How Long Does UV LED Adhesive Curing Take?

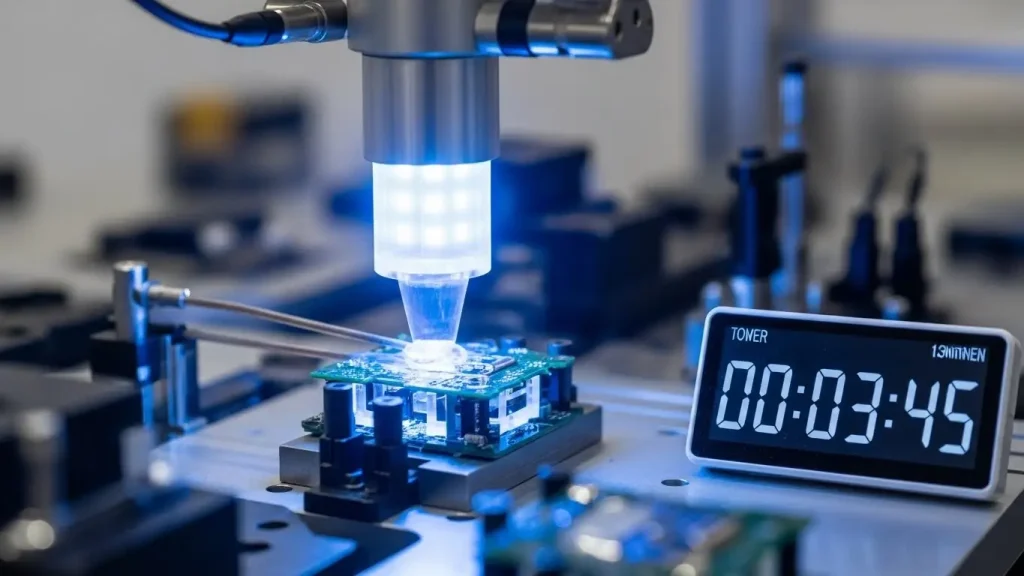

In precision assembly and industrial repair, timing is the difference between a high-strength bond and a total structural failure. While traditional curing methods might take minutes or hours, modern ultraviolet technology can often achieve full strength in seconds.

This guide clarifies how long UV LED adhesive curing takes by exploring the physics of light delivery and the chemistry of resin crosslinking. By understanding the variables that dictate cure duration, you can optimize your manufacturing cycle, reduce energy consumption, and ensure that every bond line meets its specified mechanical properties.

What Factors Determine UV LED Adhesive Curing Time?

UV LED adhesive curing time depends on adhesive chemistry, the intensity and wavelength of the UV light, the distance between the lamp and surface, and exposure duration. You will find that these four variables are fundamentally linked; if you change one, you must adjust the others to maintain a consistent result.

For instance, a high-intensity lamp can deliver the required energy dose ($J/cm^2$) much faster than a lower-powered handheld unit. Adhesives also have specific "activation thresholds"—if the wavelength of the light does not match the absorption peak of the resin's photoinitiators, the reaction will be sluggish or may not occur at all, regardless of the exposure duration.

How Does Adhesive Chemistry Affect Curing Duration?

Adhesive chemistry affects curing duration because each formulation contains photoinitiators and fillers that determine how much UV energy is needed to drive polymerization. You must consider that clear, thin-film adhesives allow UV light to pass through easily, leading to almost instantaneous curing throughout the entire layer.

In contrast, thick-gap adhesives or those containing dark pigments and structural fillers can scatter or block the light. This creates a "shadowing" effect within the material, requiring a longer exposure time or higher intensity to ensure the ultraviolet photons reach the base of the bond line. The specific concentration of photoinitiators also dictates the speed of the molecular chain reaction once triggered.

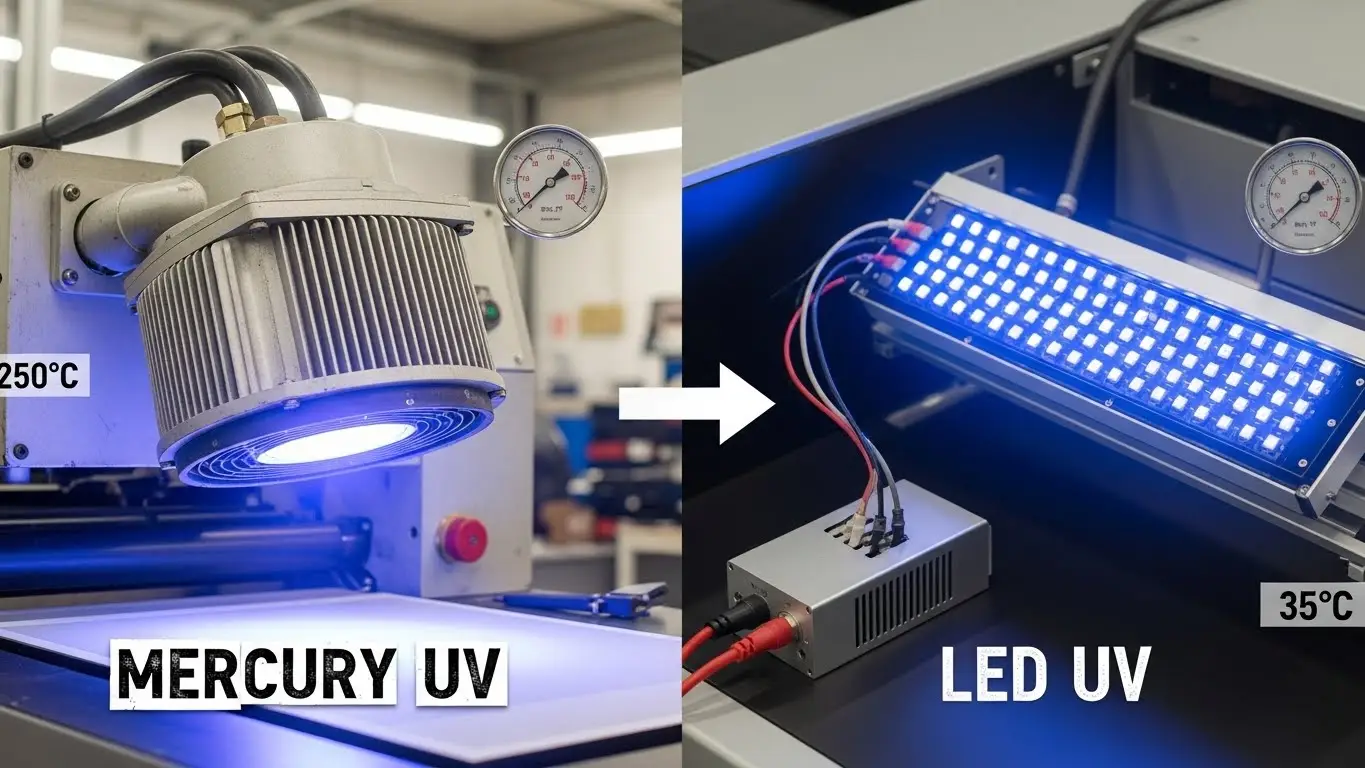

Why Do Wavelength and UV Intensity Matter for Cure Time?

Wavelength and UV intensity matter for cure time because photoinitiators only absorb specific wavelengths and higher intensity delivers the necessary energy more quickly. You can view intensity as the "pressure" of the light; the higher the $W/cm^2$, the faster the photoinitiators are "sparked" into action.

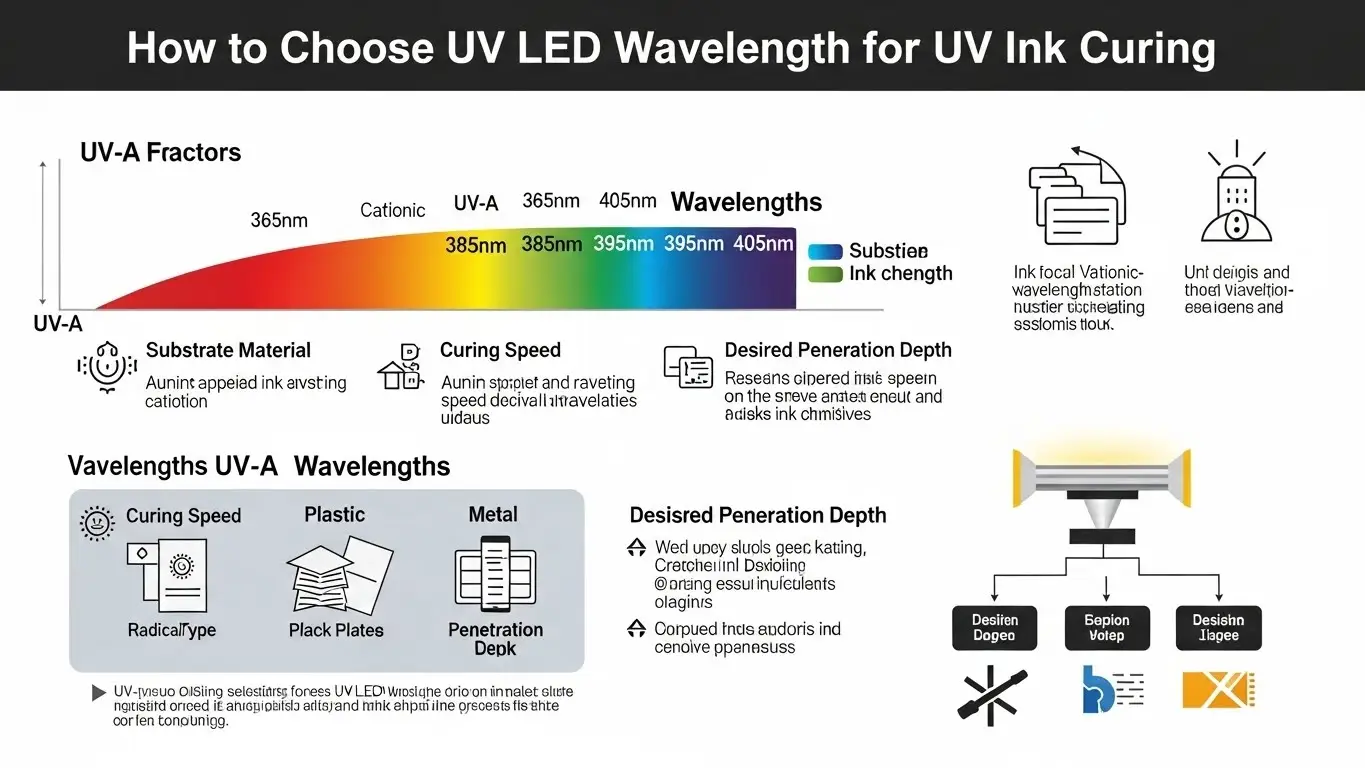

Matching the lamp’s peak wavelength (typically 365 nm, 385 nm, or 395 nm) to the adhesive’s sensitivity is critical for efficiency. If you use a lamp with a wavelength that is only partially absorbed by the chemistry, you will need to significantly increase the exposure time to compensate for the lost energy, which can lead to heat buildup and slower production speeds.

How Does Distance Between Lamp and Surface Change Cure Time?

The distance between the UV LED lamp and the surface changes cure time because intensity drops with distance, reducing the effective dose reaching the adhesive. According to the inverse-square law, doubling the distance between the lamp head and the substrate doesn't just halve the light intensity—it can reduce it to one-fourth of its original strength.

In practical applications, this means that holding a handheld lamp 10 mm from the surface will cure the adhesive much faster than holding it 50 mm away. To maintain consistency, technicians must standardize the working distance to ensure that the delivered dose ($J/cm^2$) remains within the adhesive manufacturer's specified process window.

What Practical Steps Improve Consistency in Cure Time?

Consistent cure time outcomes come from controlled positioning, understanding adhesive needs, and adjusting exposure based on intensity and wavelength. You can ensure repeatable results by implementing a structured curing protocol in your workflow:

- Standardize Fixturing: Use jigs or spacers to ensure the lamp is always held at the same distance and angle for every part.

- Use Programmed Timers: Avoid manual "counting" and rely on the lamp’s internal timer to ensure every part receives the exact same exposure duration.

- Regularly Map Intensity: Use a radiometer to verify that your lamp is still delivering its rated power, as aging LEDs can lead to longer required cure times.

- Clean Optics Daily: Ensure that adhesive overspray or dust on the lamp lens is not blocking the energy, which would otherwise force you to increase exposure time.

What Are the Key Takeaways on UV LED Adhesive Curing Time?

UV LED adhesive curing time is not a fixed number; it varies based on chemistry, UV intensity, wavelength, and how the light is applied. Mastering the balance between these variables is the key to achieving high-throughput, high-quality production.

- Intensity ($W/cm^2$) and Time work together to create the total Dose ($J/cm^2$).

- Proximity is power: Keeping the lamp close to the substrate significantly reduces cure duration.

- Wavelength alignment is mandatory to prevent slow or incomplete structural cures.

- Calibration and timers eliminate human error, ensuring every bond is structurally sound.

What Types of UV LED Spot Curing Systems Affect Cure Time?

What types of UV LED spot curing systems exist and how do they influence adhesive cure timing? Choosing a UV LED spot curing system with high-output light guides allows you to deliver massive intensity to a tiny point, often reducing cure times to under two seconds for precision assemblies.

How Do Handheld UV LED Curing Lamps Affect Cure Duration?

How do handheld UV LED curing lamps influence the practical exposure time for adhesives? While a handheld UV LED curing lamp provides portability, consistent handheld lamp usage requires the operator to be disciplined with distance to avoid variations in cure time.

How Do Adhesive Wavelength Needs Influence Cure Time?

How does matching UV wavelength to adhesive requirements impact the time needed to cure? If you select the wrong UV adhesive curing wavelengths, the efficiency of the photochemical reaction drops, forcing you to extend exposure times and potentially over-heating sensitive components.

When Are Battery-Operated UV LED Curing Lights Convenient?

When are battery-operated UV LED curing lights useful and how do they affect exposure planning? Using a battery-operated UV LED curing light or other battery UV LED curing lights is ideal for field repairs where power cables are restricted, allowing you to maintain cure time standards anywhere on a large structure.

What Is Tacky Cure and How Does Timing Affect It?

What is tacky cure and how does improper timing contribute to it? A tacky cure often indicates that the surface layer did not receive enough energy to overcome oxygen inhibition; increasing the intensity or exposure time is usually the primary technical solution.

What Safety Gear Should You Use When Applying UV LED Curing?

What safety gear is recommended when applying UV LED curing lights and why does safety matter during timed exposure? Wearing proper UV LED curing safety gear like UV-rated eyewear and skin protection is vital because even short, high-intensity cure cycles can cause significant ocular damage or skin burns.

Final Thoughts

Finalizing your cure time parameters is a step toward industrial repeatability and cost-efficiency. While it is tempting to simply "blast" the adhesive with light for a long duration to be safe, this can lead to substrate warping and excessive energy use. By scientifically matching your lamp's intensity and wavelength to your adhesive's specific chemical requirements, you find the "sweet spot" where speed and strength are both maximized. This data-driven approach ensures that your production line remains fast, your bonds remain permanent, and your overall manufacturing process remains exceptionally stable.