What Wavelength Is Best for UV Adhesive Curing?

In high-precision manufacturing, the success of a bond depends entirely on the technical alignment between the light source and the chemical resin. Choosing the wrong frequency can lead to catastrophic failures, such as delamination or internal liquid pockets.

This guide explores the critical question of what wavelength is best for UV adhesive curing by examining how different spectral bands interact with photoinitiators. By understanding the physics of light penetration and chemical absorption, you can optimize your production line for maximum bond strength and the fastest possible cycle times.

Why Wavelength Matters in UV Adhesive Curing

Wavelength matters in UV adhesive curing because the photoinitiators in the adhesive absorb UV light most effectively at specific bands, which directly affects cure speed and completeness. You can think of a photoinitiator as a lock and the UV wavelength as the key; if the photon energy does not match the absorption peak of the chemistry, the polymerization reaction will not trigger efficiently.

When the wavelengths are mismatched, the adhesive may only partially crosslink, leaving the material weak and susceptible to chemical or mechanical stress. Selecting a lamp that peaks exactly where the resin is most sensitive ensures that the maximum amount of energy is converted into a solid, durable bond.

What UV LED Wavelength Ranges Are Common for Adhesive Curing?

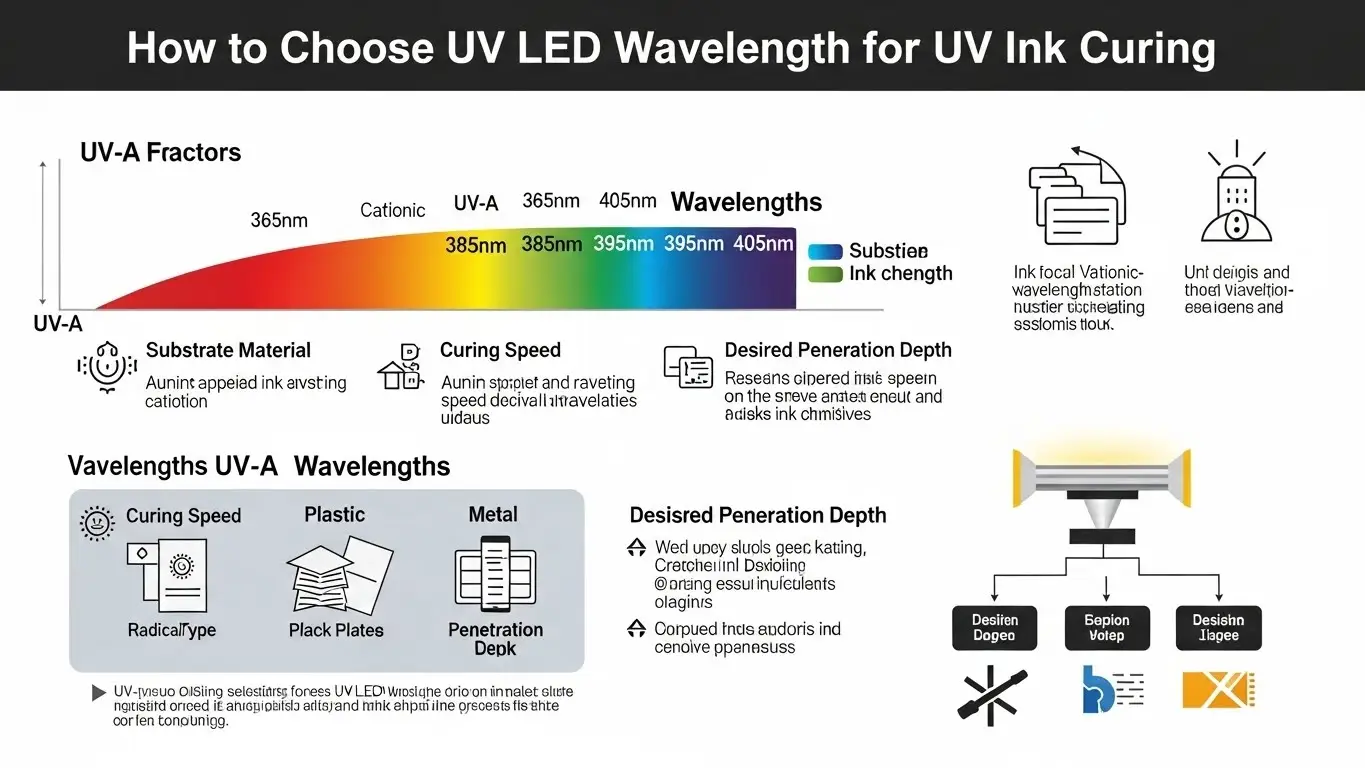

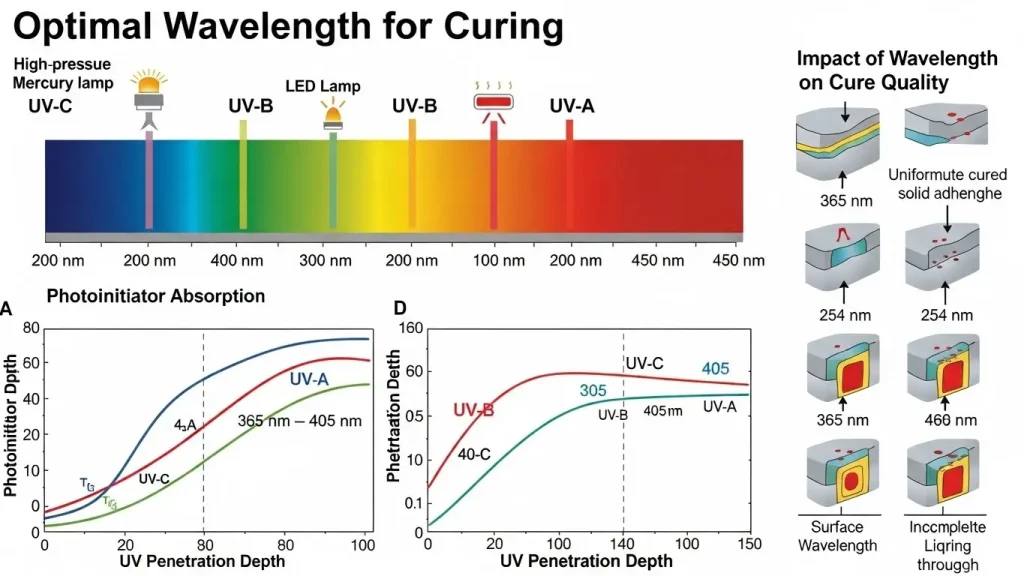

Common UV LED wavelengths for curing adhesives fall primarily in the UVA range, typically around 365nm to 405nm, with each band offering different tradeoffs in depth and speed of cure. You will find that 365nm is often considered the industrial standard for clear adhesives because it provides high photon energy for deep penetration.

As you move toward longer wavelengths like 385nm, 395nm, or 405nm, the light becomes more visible and less "aggressive," but it is often better for curing through plastics that might block shorter UV waves. These longer wavelengths are also frequently used for pigmented or highly filled resins where light scattering is a significant factor in the curing process.

How Does Wavelength Influence Depth and Speed of Cure?

Wavelength influences how deeply UV light penetrates an adhesive and how quickly it cures because different wavelengths interact with the material’s absorption and scattering properties differently. Shorter wavelengths, such as 365nm, tend to be absorbed very quickly by the top layers of the resin, which can provide an excellent surface cure but may struggle to reach the bottom of a thick bond line.

Conversely, longer wavelengths like 405nm are not absorbed as aggressively by the chemistry, allowing the photons to travel deeper into the material before they are captured by a photoinitiator. This makes longer wavelengths the preferred choice for "deep-section" curing or for bonding substrates that are not perfectly transparent to shorter ultraviolet frequencies.

How to Choose the Best Wavelength for Your Adhesive

The best wavelength for curing a specific adhesive depends on the adhesive’s photoinitiator chemistry, thickness of the bond line, and desired cure speed. You should always begin your evaluation by consulting the Technical Data Sheet (TDS) provided by the adhesive manufacturer.

- Check the Absorption Peak: Identify whether the resin is optimized for 365nm, 385nm, or 395nm.

- Evaluate Substrate Transparency: Ensure the light can pass through your parts; for example, many plastics block 365nm but allow 405nm to pass.

- Measure Bond Thickness: Use shorter wavelengths for thin films and longer wavelengths for deep potting or thick gaps.

- Assess Production Speed: Match the wavelength to your lamp's peak output to achieve the shortest possible dwell time.

What Happens When You Use the Wrong Wavelength

Using a UV wavelength that does not match an adhesive’s absorption profile can lead to incomplete cure, extended cure times, or weaker bond strength. You may observe "surface skinning," where the top layer is hard but the material underneath remains a liquid or a gel.

This leads to a phenomenon called "outgassing," where unreacted monomers escape the bond, potentially contaminating sensitive electronics or optics. Furthermore, a mismatched wavelength often results in a "tacky" surface that attracts dust and debris, compromising both the aesthetic and the functional quality of the finished assembly.

What Are the Key Takeaways on Wavelength Selection

Selecting the right UV LED wavelength is essential for consistent, effective curing because it directly affects how photoinitiators respond and how the adhesive crosslinks. Achieving a structural bond is only possible when the light source and the adhesive chemistry are in perfect spectral alignment.

- Match the peak wavelength to the adhesive manufacturer's specifications.

- Consider 365nm for high-energy, clear-bond applications.

- Use 395nm or 405nm for deep penetration or when curing through UV-stabilized plastics.

- Validate the cure through adhesion and hardness testing to ensure complete polymerization.

What Are Handheld UV LED Curing Lamps and How Do They Relate to Wavelength Choice?

How do handheld UV LED curing lamps function and why does wavelength consideration matter with these tools? A handheld UV LED curing lamp provides portable energy, but because it is often used for manual repairs, selecting a wavelength that matches your repair resin is critical for ensuring the bond is permanent.

What Wavelengths Do UV LED Spot Curing Systems Typically Use?

What wavelengths are common in UV LED spot curing systems and how do they compare? Most UV LED spot curing systems are available in 365nm, 385nm, and 395nm versions, allowing you to choose the exact spectral peak that aligns with your specific adhesive photoinitiators.

How Does Cure Time Change With Different Wavelengths?

How does UV LED wavelength influence the time required to cure an adhesive? Understanding UV adhesive curing time involves knowing that a spectral mismatch can increase exposure requirements from seconds to minutes, significantly slowing down your production throughput.

When Are Battery-Operated UV LED Curing Lights Useful?

When are battery-operated UV LED curing lights helpful? Choosing a battery-operated UV LED curing light or other battery UV LED curing lights is best for field work where you must bring the correct wavelength to the part rather than moving the part to a fixed station.

What Is Tacky Cure and How Can You Prevent It With Proper Wavelength?

What is tacky cure and how does correct wavelength selection help avoid it? A tacky cure often happens when the surface doesn't receive enough energy to overcome oxygen inhibition; using a high-intensity lamp with a properly matched wavelength is the most effective solution.

What Safety Gear Should You Use When Working With UV LED Curing Lights?

What safety gear is recommended when using UV LED curing lights at effective wavelengths? Proper UV LED curing safety gear, including UV-rated eyewear and skin protection, is mandatory regardless of which wavelength you choose, as all UVA bands can be hazardous to the eyes and skin.

Final Thoughts on Wavelength Selection

Finalizing your wavelength choice is a technical commitment to the quality of your manufacturing process. While 365nm remains the versatile choice for many clear adhesives, the shift toward longer wavelengths like 395nm and 405nm is opening new possibilities for bonding UV-opaque materials and deep-section potting.

By treating wavelength selection as a core engineering specification rather than a secondary detail, you eliminate the guesswork that leads to bond failure. The best wavelength is the one that consistently delivers a deep, through-cured bond that withstands the environmental demands of your final application.