UV Curing for Medical Device Bonding: Faster and Strong

What is UV Curing?

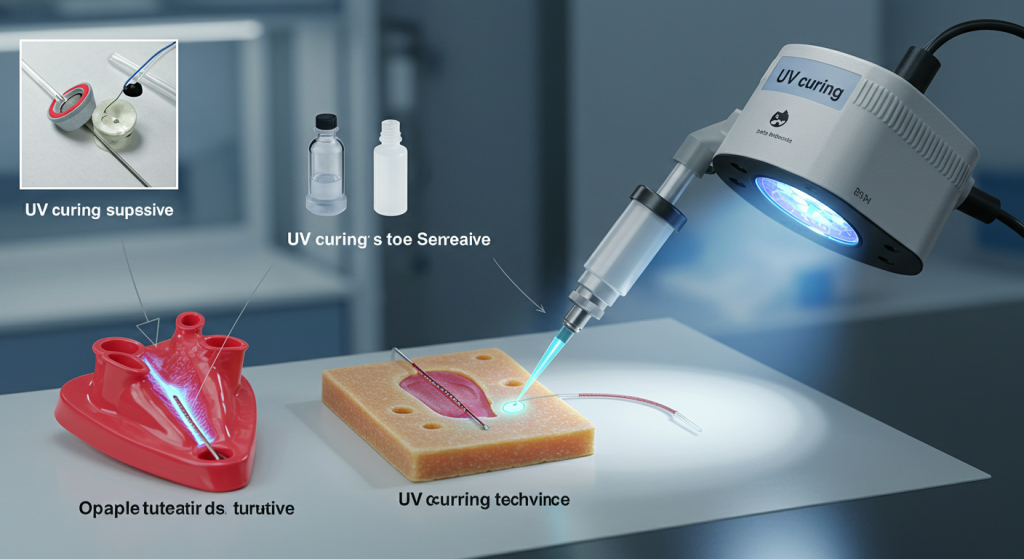

- In simple terms, UV curing for medical device bonding is a photopolymerization system-based treatment whereby the emissive UV light of selected wavelengths generates heat at a photo mask, and said heat is applied directly to specialized adhesives, enabling the latter to change state from liquid to solid quite rapidly. In most cases, this change of state is accomplished within seconds; thus, the term fast curing. Additionally, medical device manufacturers can expedite the assembly process without degrading quality.

- As opposed to traditional adhesives, which take time to dry, UV curable adhesives can be applied and cured using UV lamps or LED systems instantaneously. Thus, there are a multitude of applications for the use of curable adhesives in medicine, where accuracy, biocompatibility, and the prevention of contamination are some of the most vital factors.

The Advantages of UV Bonding for Medical Devices

The advantages of UV curing features are of significant benefit in the production of medical devices:

• Quick Assembly of Medical Devices: The use of UV adhesives permits a quick cure, which greatly increases the production rate.

• Spectrum Selection Accuracy: Accurate component assembly on a micro scale is achievable with a high degree of precision.

• Medical-grade Non-Solvent Adhesives: The absence of solvents results in lower emissions and pollutants being released into the environment.

• Structural Sturdiness of Medical Adhesives: Bonds remain intact during mechanical stress and sterilization procedures.

• Biocompatible UV Adhesives: These adhesives undergo rigorous testing of standards, such as ISO 10993, which verifies their safety when in contact with the patient.

The addition of UV curing systems allows for competitively priced medical bonding solutions without compromising product quality or compliance.

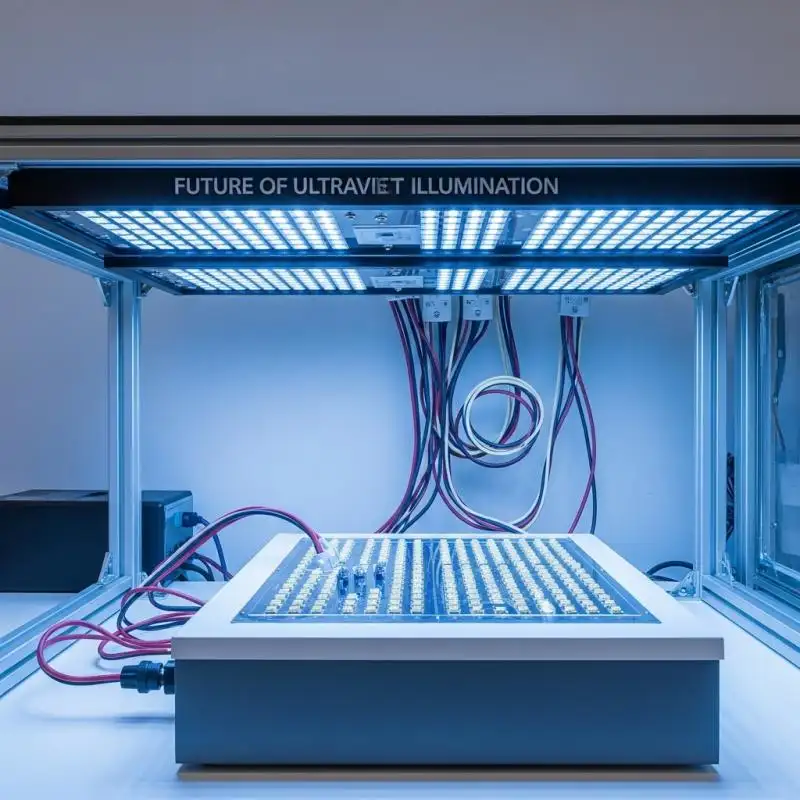

Classes of UV Curing Devices and Their Adhesives

Medical device manufacturers have the option to select from several systems for UV light curing. Each system is designed for specific applications:

• Medical UV Curing Lamps: Mercury vapor or metal halide lamps emit broad UV wavelengths for deep curing.

• LED UV Curing: LEDs have greater energy efficiency, longer lifespan, and emit targeted wavelengths, making them more efficient.

• UV Spot Curing: Optimal for small area precision bonding tasks such as sensor attachment.

• UV Flood Curing: Suitable for larger surface areas or batch processing.

Within adhesives, there are formulations of medical-grade UV curable resins for medical devices, which are UV adhesive irradiated grades with superior sterilization resistance (autoclave, ETO, gamma). These adhesives exhibit good bond strength to a variety of substrates, including medical plastics (PC, PVC, and PMMA), biocompatible polymers, stainless steel, and glass.

Applications in Medical Device Manufacturing

The versatility of UV curing for medical device bonding is evident in the numerous assembly adhesive applications as follows:

• Catheter Bonding: Achieves secure, leak-proof seals on tubing joints.

• Syringe Assembly and Needle Bonding: Minimizing production bottlenecks with fast curing.

• Medical Tubing Bonding: Durable, flexible seals.

• Endoscope Assembly: Low shrinkage and optical clarity.

• Wearable Medical Device Bonding: Requires biocompatible and non-irritating to skin adhesives.

• Microfluidic Device Bonding: Bonding of micro-scale channels and sensors with precision.

• Respiratory Mask Assembly and IV Set Bonding: Critical need for sterilization resistance and strength.

Compatibility and Operative Performance

Affixing to medical substrates is very important. UV adhesives have good bonds with common materials like polycarbonate (PC), PVC, polymethyl methacrylate (PMMA), polyethylene (PE), stainless steel, and glass. The adhesives must have the following properties:

• Sterilization resistance: Bonds survive autoclaving, ethylene oxide (EtO), gamma, and E-beam sterilization effects without deterioration.

• Low shrinkage adhesives: Guarantees no undue stress is placed on primary, delicate components.

• Optical clarity: Essential in medical optics and other diagnostic apparatus.

• Tack-free cure: Avoids contamination during assembly processes.

Compliance and Regulatory Standards

All industry segments have a set of rules or standards that must be followed as legally binding for any undertaking. In the case of medical devices, the requirements are highly prescribed. The bonding done using UV adhesives is regulated by:

• ISO 10993 ascribable to biocompatibility.

• USP Class VI implantable device marking.

• Relevant regulations on medical devices concerning patient safety and dependability of the product.

Automation and Production Efficiency

Automated systems for bonding with UV have their fitting inside the process of manufacturing medical products, and so enhance:

• Increased rate of production.

• Consistency and precision in the process of bonding.

• Lowered costs incurred for labor and human error.

For those considering the enhancement of the process of medical bonding at minimal costs, the combination of automation with UV curing stands out the most.

Choosing the Best UV Curing Solutions for Medical Device Bonding

Bonding medical devices requires precise ant disinfectant biocompatibility. Polymeric medical-grade UV adhesives are ideal since they are instant bonded using proprietary techniques that require UV light exposure for curing, chargeable, measurable polymerization.

Key Features to Follow

While searching for a UV medical device curing solution, pay attention to:

• Polymer Compatibility: Ensure that the polymer to be bonded, such as medical devices which involve PC, PVC, stainless steel, and glass, is favorable as a substrate to guarantee proper adhesion.

• Adhesive: Select medical-grade polymer UV adhesives fulfilling the ISO 10993 epoxy and USS classification of IV. These materials are proven flammable for patient-contact applications.

• Curing apparatus: Employ Cast Ray Dutch medical grade UV lamps or systems of LED UV curing medics, which have a high guarantee of delivering of constant magnitude of ultraviolet light throughout the curing period for maximum strength and speed of curing.

• Sterilization Resistance: The adhesive in question has to survive procedures like autoclaving, EtO, and gamma radiation without losing its integrity.

Benefits of the Right UV Curing Solution

The optimal UV curing for medical device bonding elevates production speed, strengthens the reliability of the bond formed, and facilitates economical medical bonding. It also guarantees adherence to stringent regulatory requirements important for medical device fabrication. Tailored UV curing solutions are available at UVNDT, where advanced UV adhesives are designed to improve the medical device bonding process.

Conclusion

Medical device bonding UV curing is arguably the most sophisticated blend of speed, accuracy, and adherence to regulations. Ranging from flexible tubing to intricate microfluidics, UV curable adhesives pose numerous advantages for the medical devices market by making them safer, faster, and more reliable to produce. Step into the new age of medical devices, UV bonding, and enhance your manufacturing processes with the integration of advanced UV curing technologies. Visit UVET.