Accurate Tools used in Ind-ITC and Quality Control

In modern-day high-precision manufacturing and industrial processes, UV fluorescence inspection has become a vital technique used to identify defects, cracks, and contaminants on surfaces. This technique utilizes the ultraviolet light characteristic of having the ability to reveal otherwise invisible defects to produce high-resolution UV imaging of a broad selection of materials, such as metals, polymers, coatings, and adhesives.

Industries are able to determine quality, compliance, and safety by using ultraviolet fluorescence inspection systems to enhance efficiency. These systems involve the usage of UV light inspection, fluorescent dye inspection, and high-level non-destructive UV testing (NDT) in order to provide consistent, reliable results.

The Insight into UV Fluorescence Inspection

The UV fluorescence inspection is a non-destructive testing (NDT) technique, which employs the use of ultraviolet (UV) light to produce fluorescence with dyes, coatings, adhesives, or some materials. The imperfections or contaminants fluoresce when UV light is thrown on a surface, and can be detected by the inspectors.

The main benefits of the approach are:

- Small cracks or defects. High-resolution UV inspection.

- Quick UV fluorescent analysis with real-time visual display.

- Sensitive materials inspection to controlled UV exposure.

- Handheld UV inspection systems.

The process finds extensive use in UV fluorescent dye inspection, UV penetrant inspection, and UV defect detection systems. By integrating accurate UV light source inspection and surface flaw fluorescence testing, industries can recognize defects that cannot be observed under standard lighting conditions.

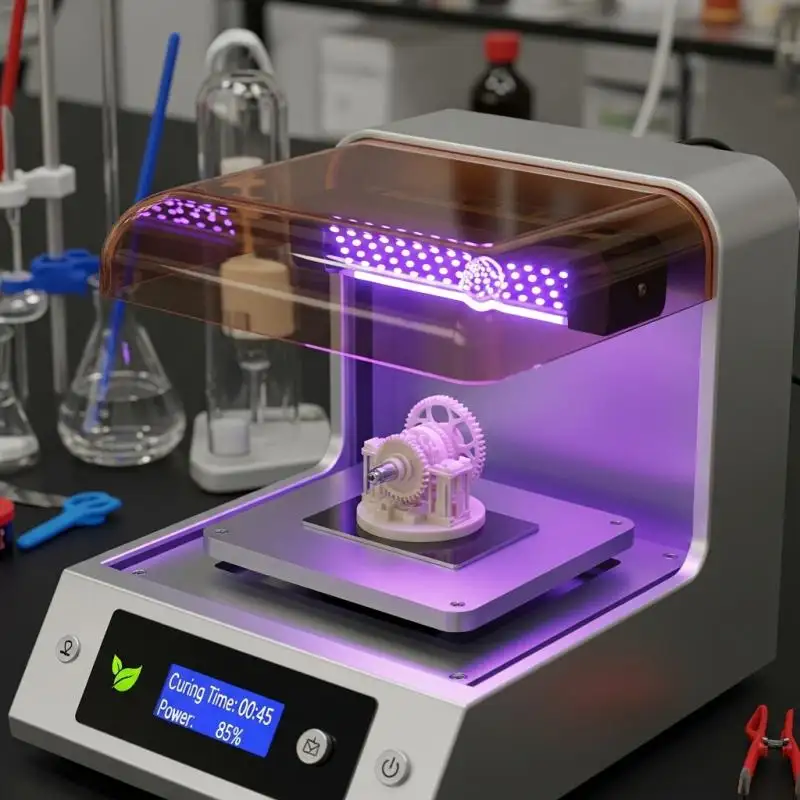

UV Inspection Systems are automated

The automated UV fluorescence inspection systems automate the quality control in production lines. Features include:

- LED UV inspection technology provides accurate and consistent UV illumination.

- UV inspection to prevent damage to delicate parts due to temperature changes.

- Non-invasive high-resolution UV fluorescence tracking in human intervention.

- Continuous monitoring by incorporating industrial UV monitoring equipment.

The systems have found extensive applications in semiconductor UV inspection systems, PCB UV inspection, and optical component UV inspection to ensure high-precision UV fluorescent tests.

Materials

The inspection by UV fluorescence can be adapted to particular materials:

UV inspection of metals - Cracks, surface, and corrosion detection.

Polymer fluorescence inspection - Determines discrepancies in coating or adhesive layers.

UV adhesive fluorescence inspection - Provides the correct connection in electronics and medical equipment.

UV inspection of coatings - Pinholes, scratches, and contamination detection.

Ultraviolet dye penetrant testing – this method can reveal cracks and defects on hard surfaces that are not easily visible to the naked eye.

With the help of fluorescent penetrant testing under controlled UV exposure, inspectors can obtain the accuracy of UV defect detection and surface flaw fluorescence inspection of a large range of industrial materials.

Industry Applications

Semiconductor Industry Electronics

UV inspection is applied to PCB inspections, semiconductor wafer defects inspection, and microelectronics quality control in electronics. Fluorescent-UV testing guarantees that adhesives, coatings, and solder joints are of high quality, and therefore, they do not fail and lead to higher reliability of any device.

Automotive & Aerospace

Auto UV inspection machines are applied in testing the surface cracks, paint defects, and adhesive failures in high-precision components. Likewise, aerospace UV fluorescence is used to make sure that safety-critical components are devoid of structural defects.

Oil & Gas Industry

The UV fluorescence examination is used in the identification of leakages, corrosion, and cracks in pipelines and equipment. The portable UV inspection systems enable the inspector to use high-intensity UV examination and conduct rapid UV fluorescent tests in the field.

Medical Equipment and Optical Parts

Medical devices and optical components manufacturers refer to UV fluorescence testing in order to identify correct adhesive hardening, the surface condition, and flawless assemblies. High-resolution UV inspection systems allow accurate UV defect detection, which is crucial for safety and performance.

The benefits of UV Fluorescence Inspection

- Good Precision and Resolution

- Identifies micro-cracks, surface defects, and cracks in adhesive.

- Good in case of very precise UV fluorescent analysis.

Fast and Efficient

- On-site inspection of defects.

- Facilitates fast UV examination.

Non-Destructive Testing

- NDT does not destroy materials.

- Applicable to metals, polymers, coating and adhesives.

Portable and Versatile

- Field inspection can be done with devices such as the UV150B UV LED Inspection Lamp.

- Durable, rechargeable, and light.

Energy-Efficient and Safe

- LED UV inspection technology consumes less power.

- UV inspection allows the protection of delicate substrates in the case of a temperature-sensitive system.

UV LED Inspection Lamp (UV150B)

The UV150B UV LED Inspection Lamp is a portable device that is used to examine UV fluorescence.

Key Features:

- 365nm UV-A LED light source

- Peak intensity: 6000uW/cm2 at 380mm

- UV beam size: Ph150mm

- Battery: rechargeable lithium-ion, about 2.5 hours of operation.

- The body is made of anodized aluminum that is durable.

Applications:

- Nondestructive testing (NDT)

- Fluorescent leak detection

- Forensic inspection

- Industrial and laboratory quality control.

Advantages:

- High-intensity UV light at an instant.

- Durability, anti-corrosive design.

- Small size, lightweight, and extended power.

In accordance with ASTM UV-A standards of LPT and MPT.

The lamp will be used to obtain accuracy in the identification of defects in industrial UV fluorescence inspection based on precision UV lighting, where the lamp is capable of delivering quick, consistent, and reliable check-ups even in harsh conditions.

Selection of the correct Inspection Tool

When picking a UV inspection system, it should take into consideration:

Material Compatibility - Metals, polymers, coatings, or adhesives.

Type of Inspection - Portable, stationary, or automated.

Resolution and Sensitivity - To detect defects with high precision.

UV Light Source, LED, UV-A, or other wavelengths.

Compliance & Standards - ASTM or ISO standards of NDT.

High-quality UV fluorescent inspection equipment can be used to guarantee maximum optimization in the UV inspection process, detection of surface flaws, and high-intensity UV inspection to get reliable and reproducible results.

Conclusion

UV fluorescence inspection is an essential instrument to use in industrial, electronics, automotive, aerospace, and medical industries. With portable UV LED inspection lamps to automated high-resolution UV inspection systems, the technologies have offered non-destructive, accurate, and efficient testing on a large variety of materials.

These systems permit accurate UV defects detection and surface defects fluorescence that are out of the strict industrial standards using advanced LED UV inspection technology, controlled UV exposure, and high-intensity light. The UVET UV150B UV LED Inspection Lamp is a portable device, designed to be durable and meet the ASTM standards, which is why the UV150B is suitable for conducting field inspections, NDT, quality control, and forensic work.

Browse our UV inspection systems and take the inspection processes up a notch.