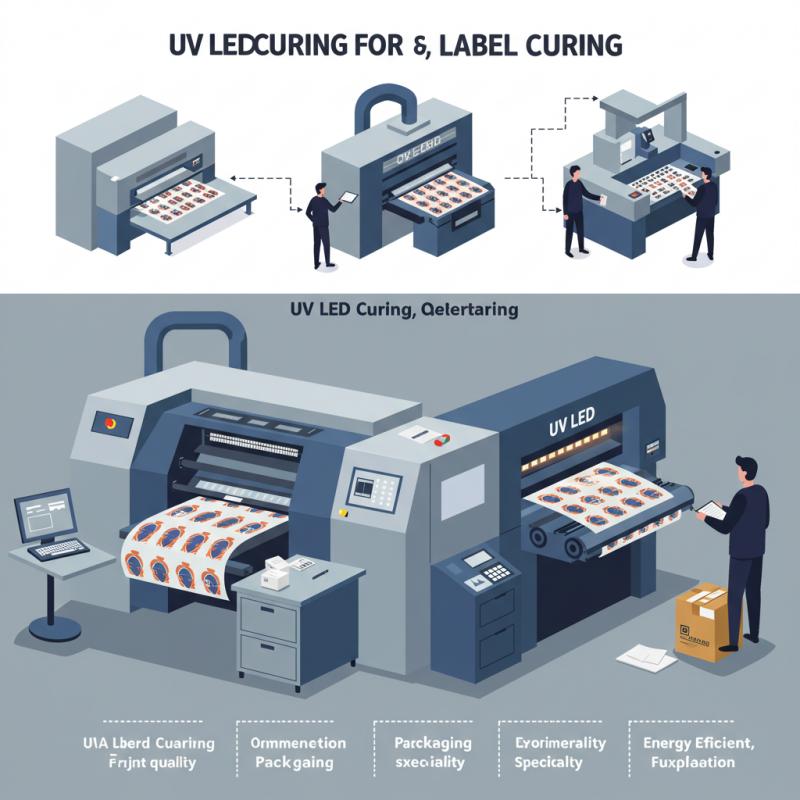

What is UV LED Curing of Labels?

- UV LED curing for Labels is a recent improvement facing the process of printing, which is carried out through the use of ultraviolet lighting-emitting packages (UV LEDs). UV LED label curing, unlike conventional drying methods of thermal heating, is energy efficient, non-thermal, and results in high-quality prints not subject to merging. The technology offers fast ink polymerization, good color stability, and increased adhesion to the substrate in commercial and packaging labels.

- Food and beverage labeling, cosmetics, pharmaceuticals, and packaging industries are among those that can exceptionally profit from the given innovative solution. UV NDT is the place to learn more about our advanced systems.

Benefits of Non-Thermal Curing

As opposed to mercury or heat-based systems, UV LED label curing is thermally neutral, and thus substrates will not distort, nor will any heat-sensitive materials be damaged. PVC, PET flexible films and foils, as well as smooth paper, maintained their originality whilst they were drying quickly.

- Overnight Dry-Ink

The UV LED curing is high speed; thus, production downtimes are minimized. It handles micro portable curing and also large-scale level label presses.

- Enables Accelerated Manufacturing with Instant Curing

UV LED curing technology is much faster than the conventional printing technique. The manufacturers have the opportunity to produce at high speeds continuously with UV inks by taking advantage of their quick-drying properties, enabling the instant polymerization of the inks. The immediate curing eliminates downtime, smudging, and makes the prints ready to be handled or finished immediately. UV LEDs allow large-scale commercial printers, as well as on-demand label presses, to gain higher productivity and maintain the quality of output.

Sensitive Materials are preserved under Low-Heat Operation.

As opposed to more conventional curing technologies that involve too much heat, UV LED systems produce negligible heat radiation, hence usable in heat-sensitive materials like films, PVC, PET, and even coated papers. This guarantees there is no warping, distorting, or spoilage of sensitive materials and results in fine, crisp images.

Self-Power and Eco-friendly

UV LED curing removes mercury lamps and lowers the production of ozone, and saves more than 50 percent of energy use. LED lamps have also been noted to have a long life span beyond 20,000 hours, and this reduces their maintenance and running costs.

UV LED Cure Label Types of Systems:

There are many ways that labels can be cured using UV Led Curing For Labels, but two major categories: types of label printing and types of label application There is no single system to cure labels because there are several possible ways to print labels and then discharge the labels, and because there are several possible ways to apply labels to the substrate.

LED UV Curing Presses at High Velocity

The systems are commercial-grade industrial systems developed to label large volumes and achieve good results with fast ink polymerization and constant quality printing results throughout the production batch.

Handheld and mobile UV LED Curing Solutions.

With low weight and energy requirements, transportable machines are best suited to on-demand and specialized label production, where one can cure small lots immediately without a full press.

UV LED Modules Label Presses

Existing presses can be retrofitted with modular LEDs to scale, make flexible and efficient use of their label production processes, allowing manufacturers to scale without having to change their whole system.

Benefits of UV LED label curing

- Energy Efficiency: Uses more than 50 percent less energy than conventional mercury lamps.

- Eco-Friendly: mercury-free, ozone-free, and sustainable.

- Fast Curing: Shortens production time and improves throughput.

- Strong Adhesion and durability: This makes sure of strong and long-lasting prints of the labels.

- Non-Destructive: Does not use heat to work on sensitive substrates.

UV LED Curing of Label Applications

- Printing Labels Commercial

Applied to large-scale production of beverages, food, and consumer labeling.

- Packaging Label Manufacturing

UV LED label curing delivers consistent bright colors to cartons, foils, and flexible packages.

- Curable Labels

Any stronger bonding of pressure-sensitive or specialty adhesive labels.

- Flexible, Specialty Labels

It is best suited for shrink sleeves, stretchable films, and customized packaging.

UV LED Curing Performance & Productivity Advantages

- Unified Quality of Color and Prints

UV LED curing guarantees very even polymerization of inks and vivid, striking colors on all prints. Such consistency plays a crucial role in branding and quality packaging use.

- Energy Efficiency

UV LED systems have lower power consumption than traditional mercury lamps, hence making the operations less expensive and environmentally friendly.

- Quicker Throughput and Shorter Meltdowns

Instant curing of chemicals in the ink enables handling of the print instantly, shortening the production plan. Fast curing eliminates time lapses and makes the printing operation easy in commercial premises.

- Low Cost of Maintenance

The lamps used, LED lamps, last more than 20,000 hours, and this means that there is less need to change them, and less maintenance takes place, hence, overall savings in operating costs.

- Safer Operations and Low Heat Emission

UV LED systems produce low thermal radiation that is applied in preserving the integrity of heat-sensitive products like films, PVC, PET, and coated papers without compromising the safety of the operator.

UV LED label curing Tools & Equipment

- UV LED Press Label Curing

These industrial presses are high-speed, suitable for continuous one-label production, and come with immediate ink curing and steady output quality on huge volumes. Very good at commercial packaging operations.

- Handheld Curing Lamps

Mobile or handheld UV LED lamps are ideal to be used for on-demand or small-scale applications, where labels can be printed and immediately cured with the use of portable UV LED energy without the need to invest in a full-scale press.

- LED Building Blocks

The retrofit modules are flexible enough to be inserted into the existing label presses. The modules allow effective upgrades in the system without having to replace the system as a whole. They facilitate power savings, curing, and customizable designs.

Conclusion

UV LED curing for Labels is changing the label printing industry by ensuring these characteristics of speed, efficiency, and high-quality output. Instant ink polymerization, non-thermal curing, and low-energy requirements give manufacturers the ability to manufacturers to provide consistent color, high adhesion, and robust labels with a wide variety of substrates. It is also environmentally friendly, mercury-free, and in concurrence with current trends of sustainability. Visit UVET.