Is UV LED Curing Worth It? Cost, Savings, and Payback

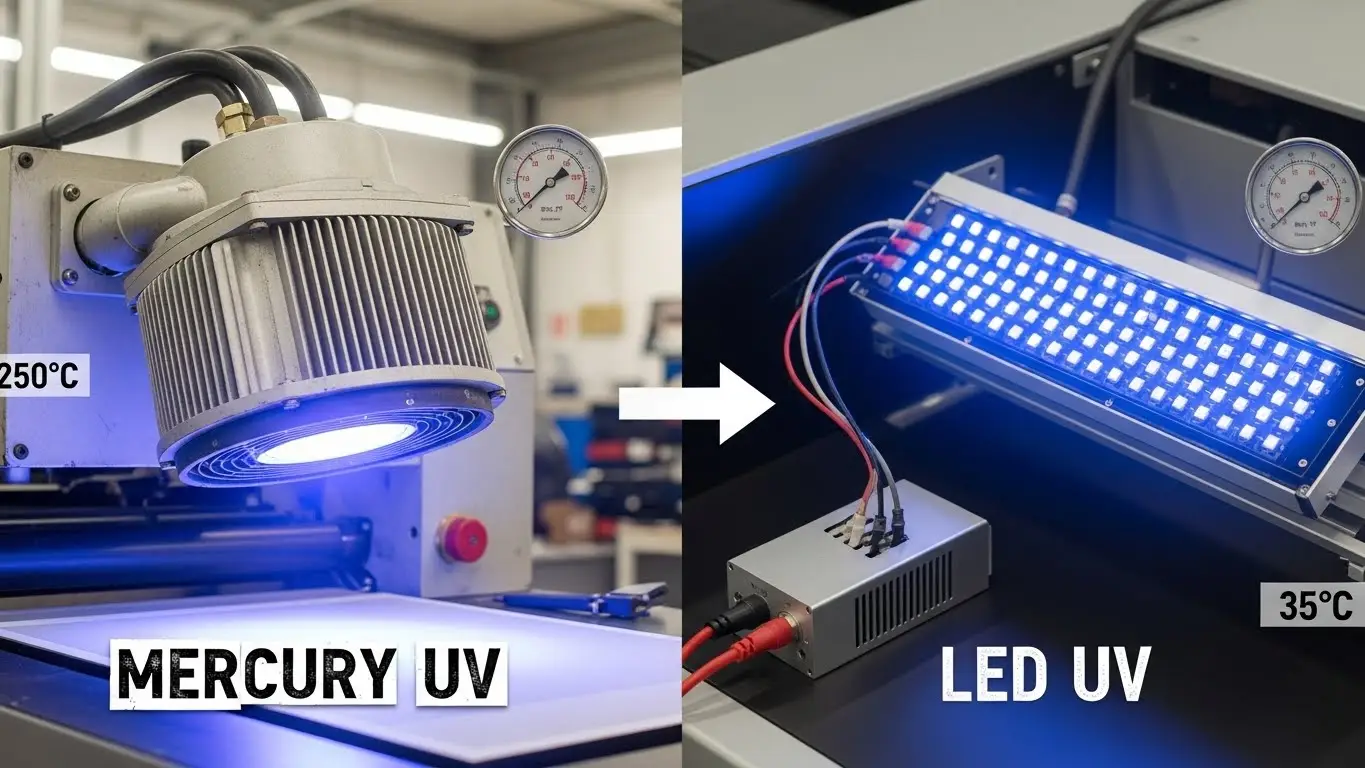

Deciding to invest in new ultraviolet technology requires you to move past technical specs and analyze the financial reality of your production floor. While traditional mercury systems have been the standard for decades, the shift toward solid-state curing is driven by a desire to reduce operational overhead.

This guide examines the UV LED curing cost savings and investment factors you should consider before making the transition. By looking at total cost of ownership rather than just the initial price tag, you can determine if the operational benefits align with your facility's long-term financial goals.

What Does UV LED Curing Cost Up Front?

The upfront cost of a UV LED curing system includes equipment purchase, installation or integration, and any ancillary hardware needed for your process. You will find that the initial price of an LED system is often higher than a comparable mercury-arc lamp due to the complexity of the semiconductor arrays and the digital controllers required to drive them.

Integration costs can also vary depending on whether you are buying a self-contained handheld unit or retrofitting a multi-lamp array into a high-speed press. However, you should account for the fact that LED systems do not require expensive ozone extraction ducting or heavy high-voltage ballasts, which can offset some of the initial facility preparation expenses.

Where Do Savings Typically Come From?

Savings with UV LED curing typically come from lower energy use, reduced maintenance, and longer usable life of key components. You will see the most significant impact in your utility bills, as LEDs convert electricity to UV light much more efficiently and only draw power when they are actually curing.

Unlike mercury bulbs that require replacement every 1,000 to 2,000 hours, LED diodes are rated for 20,000 hours or more. This longevity eliminates the frequent cost of replacement bulbs and the labor associated with swapping them. Because LEDs generate less radiant heat, you also save on the energy required to cool your substrates or maintain your factory's ambient temperature.

How UV LED Curing Can Affect Throughput and Efficiency

UV LED curing can influence throughput and efficiency because LEDs turn on instantly and hold consistent output without warm-up delays. You can eliminate the 15-to-30-minute waiting period required by mercury lamps to reach full intensity, allowing you to start production immediately.

This "instant-on/off" capability is especially valuable in intermittent workflows where the light can be cycled with the movement of the product. By removing these idle periods, you increase your total daily machine uptime. Consistent output over the life of the diodes also means you spend less time troubleshooting under-cured parts, which helps maintain a high first-pass yield and reduces the cost of scrap.

What Determines Payback Period?

Payback period for a UV LED curing investment depends on usage intensity, energy costs, maintenance requirements, and how quickly savings from operation offset upfront cost. If your facility runs two or three shifts a day, your high utilization rate will allow the energy and maintenance savings to recover the initial investment much faster.

Facilities with high electricity rates or strict environmental compliance costs often see a shorter payback window. You should also factor in the "hidden" savings of reduced downtime; if your line no longer stops for lamp failures or shutter jams, that reclaimed production time contributes directly to your return on investment.

When UV LED Curing May Not Be the Best Fit

UV LED curing may not be worth the investment when production volume is low, existing equipment already meets needs, or the specific process isn’t well matched to LED output. You should carefully assess your utilization; if you only use your curing lamp once a week for small repairs, the long-term energy savings may never offset the higher initial purchase price.

Some specialized chemistries still require the broad-spectrum "UVC" energy that only mercury lamps provide. If your material supplier does not offer an LED-compatible version of your resin, the cost of reformulating your chemistry might outweigh the operational benefits of the hardware. In these cases, maintaining your current setup is often the more fiscally responsible choice.

How to Evaluate Value for Your Operation

Evaluating the value of UV LED curing requires comparing total cost of ownership, expected operational savings, and how the system supports your production goals. You should start by collecting real-world data from your current curing process, including annual bulb costs, energy consumption, and maintenance hours.

- Define Usage: Estimate your actual "lamp-on" hours per year.

- Model Energy Savings: Compare the wattage of your current system against an LED alternative.

- Calculate Maintenance: Include the price of bulbs, filters, and the labor to install them.

- Consider Quality: Factor in the cost reduction from fewer rejects due to thermal damage.

- Request an ROI Model: Ask suppliers to provide a detailed payback analysis based on your specific production data.

What Are the Key Takeaways on Cost, Savings, and Payback?

UV LED curing can be financially worthwhile when its operational advantages align with actual production needs, usage frequency, and cost structures. It is a technical upgrade that pays for itself through discipline and high utilization.

- Upfront investment is higher, but the long-term cost of ownership is lower.

- Energy and maintenance are the primary drivers of your operational savings.

- Instant-on capability improves machine uptime and daily throughput.

- High-volume users see the fastest payback and the greatest return on investment.

How Do UV LED Spot and Handheld Curing Systems Affect Cost Profile?

How do UV LED spot and handheld curing systems influence cost and savings? Using UV LED spot and handheld curing tools for manual assembly or repairs can reduce costs by allowing for localized energy delivery. This precision ensures you only pay for the energy needed for the bond itself, rather than heating an entire part.

How Do UV LED Spot Curing Systems Compare in Investment Level?

How do different UV LED spot curing systems vary in purchase and operating cost? You can choose between a single-wand UV LED spot curing system for low-volume work or multi-channel spot curing systems for automated lines, where the higher initial cost is offset by faster cycle times.

How Do Handheld UV LED Curing Lamps Influence Payback?

How do handheld UV LED curing lamps affect expected savings? While the initial handheld lamp purchase is modest, the real payback comes from its versatile usage in field repairs, potentially saving you the cost of transporting large assemblies back to a factory for fix-ups.

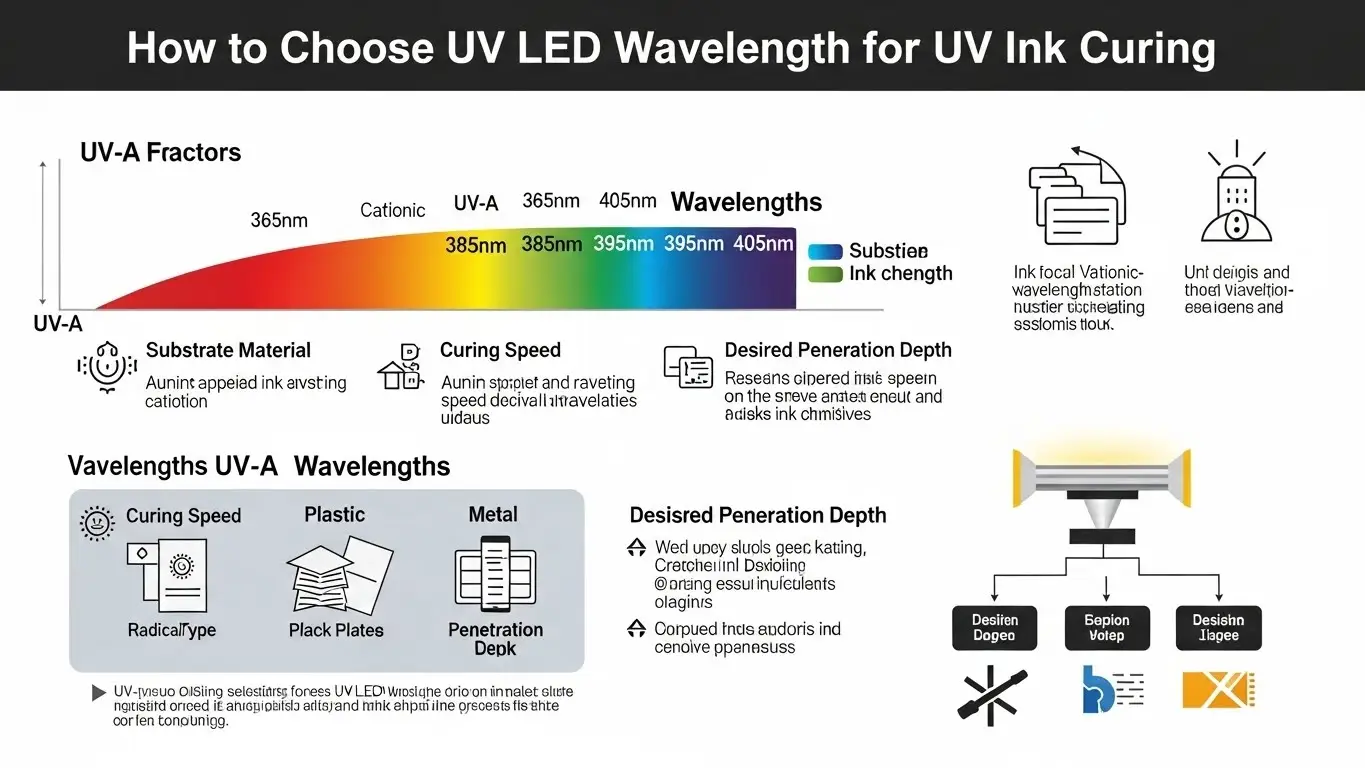

How Do Wavelength and Cure Time Influence Operating Costs?

How do wavelength and cure time affect your costs? Selecting the correct UV adhesive curing wavelengths ensures the most efficient energy absorption. A perfect match reduces your required UV adhesive curing time, which directly lowers the electricity consumed per part.

Can Battery-Operated UV LED Curing Lights Change the Cost Equation?

Do battery-powered units change your financial planning? Using a battery-operated UV LED curing light or other battery UV LED curing lights eliminates the cost of running power lines to remote areas, though you must account for the long-term cost of replacement battery packs.

Final Thoughts

Finalizing your decision on UV LED technology is a matter of aligning your production volume with the system's efficiency gains. While the high initial cost can be a hurdle, the elimination of mercury bulb changes and the dramatic reduction in energy consumption create a compelling case for high-volume manufacturers. By running a detailed total cost of ownership analysis, you move from an emotional purchase to a data-driven business decision. The most valuable system is the one that not only cures your adhesive perfectly but also contributes to a more profitable and sustainable manufacturing operation.

- PREV: How to Retrofit from Mercury UV to LED UV (What to Expect)

- NEXT: Null