UV LED Curing System Maintenance: Simple Checklist for Uptime

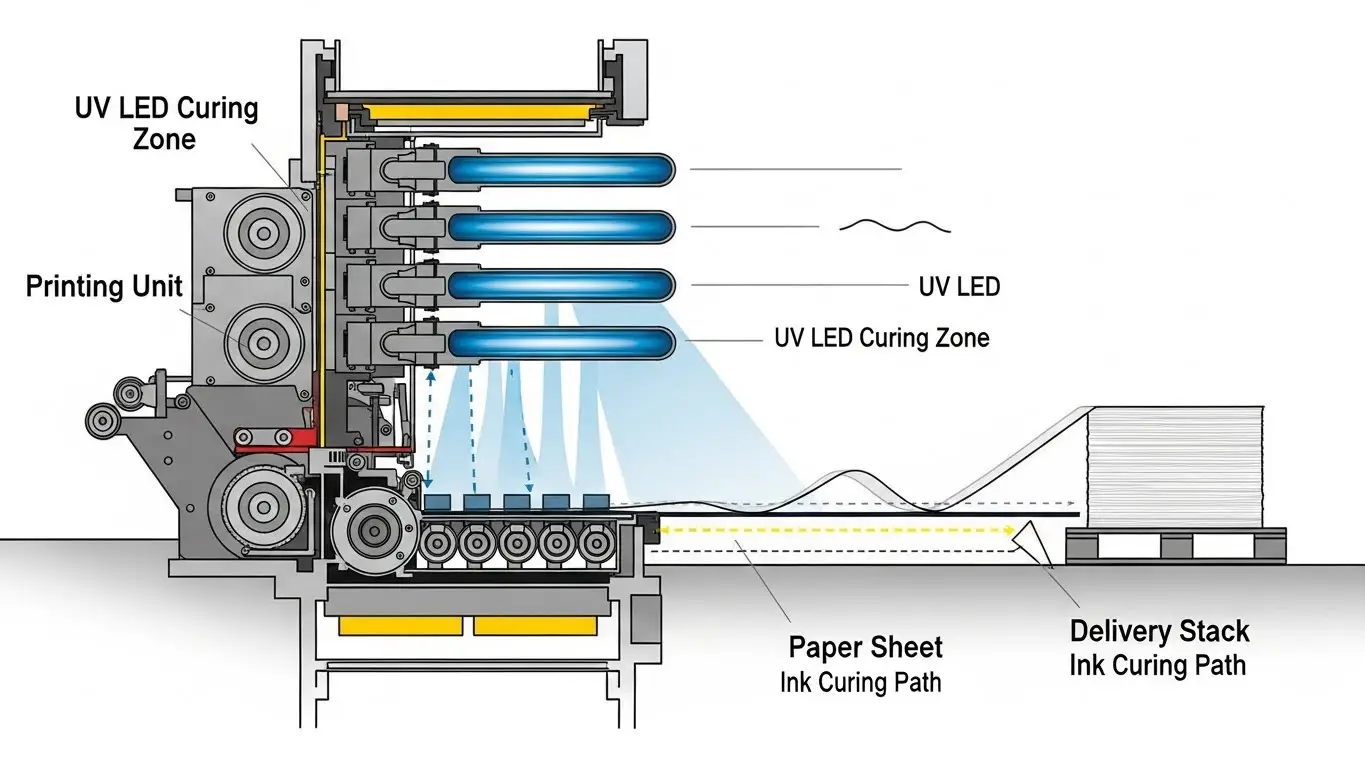

Ensuring your manufacturing process remains predictable requires a proactive approach to equipment care. While ultraviolet LED technology is known for its durability and long operational life, it is not a "set-and-forget" system.

This guide provides a structured UV LED curing system maintenance checklist designed to help you prevent intensity drift, manage thermal loads, and avoid the high costs of unplanned downtime. By implementing these simple daily and periodic checks, you can maintain the high-precision performance required for your industrial adhesives, inks, and coatings.

Why Is Regular Maintenance Critical for UV LED Curing Systems?

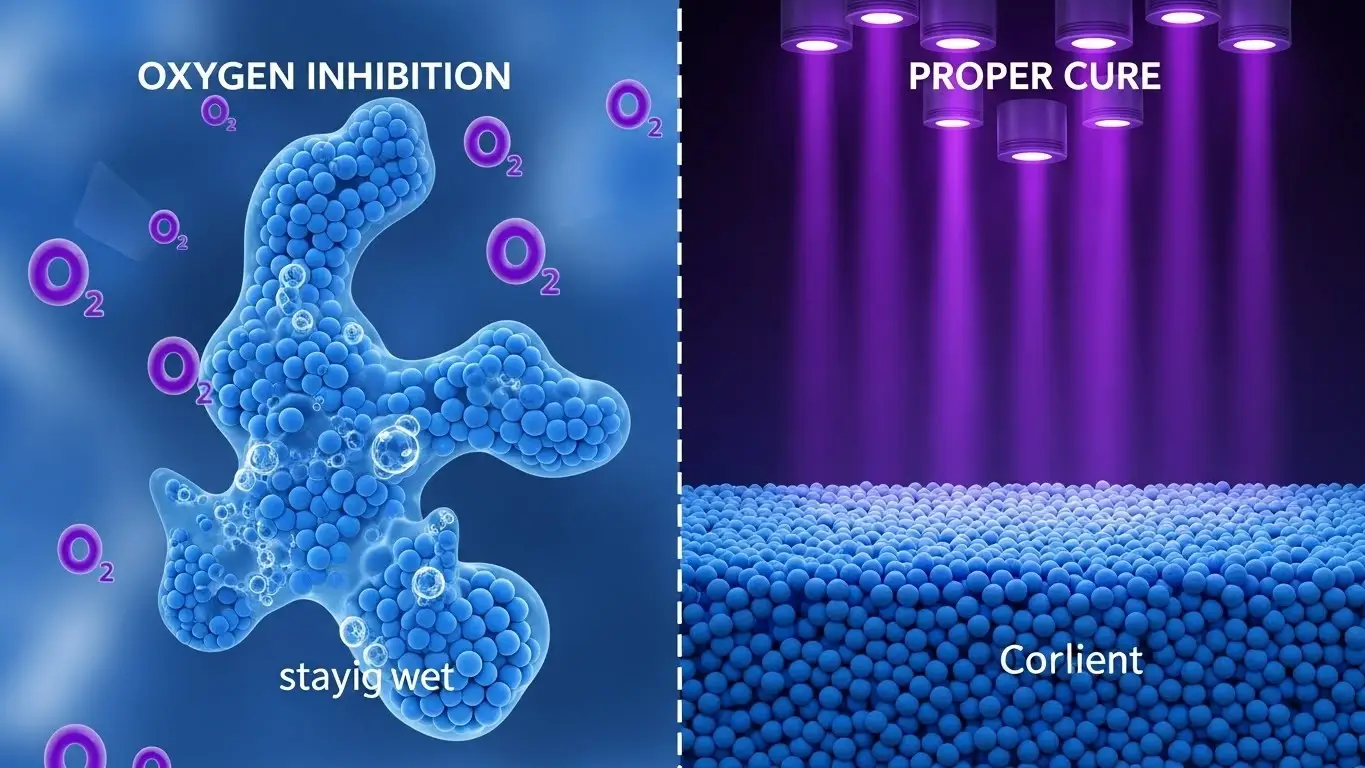

Regular maintenance is critical for UV LED curing systems because it preserves intensity stability, prevents unexpected downtime, and supports consistent curing performance throughout production. You will find that even a thin layer of dust on the output window can significantly reduce the ultraviolet energy reaching your part, leading to soft surfaces or bond failures. Furthermore, keeping the thermal management systems in peak condition ensures that the diodes do not overheat, which is the most common cause of premature LED degradation. Consistent care turns your curing station into a reliable, data-driven component of your production line.

What Daily Checks Should You Perform?

Daily checks for UV LED curing systems should include verifying airflow or coolant flow, checking for visible debris or dust on optics, and confirming that system status indicators are normal. You can integrate these tasks into your shift-start routine to ensure that every part cured that day meets your quality standards.

- Inspect the Window: Wipe away any dust, overspray, or fingerprints from the protective lens using a lint-free cloth.

- Confirm Cooling Status: Check that fans are spinning freely or that the liquid chiller shows the correct flow rate and temperature.

- Monitor Indicators: Look for any warning lights or error codes on the power supply unit that might indicate a fluctuating voltage or thermal issue.

- Listen for Irregularities: Note any unusual fan noise or pump vibrations that could signal a developing mechanical failure.

What Weekly or Monthly Tasks Support Reliability?

Weekly or monthly maintenance tasks typically include cleaning optical surfaces, inspecting electrical connections, and measuring output intensity to detect drift or degradation. You should use a calibrated radiometer to map the light output across the curing field, as this allows you to catch any localized "cold spots" before they affect your product quality. Checking the integrity of high-voltage cables and connectors prevents intermittent power issues that could lead to flickering or total lamp failure. These periodic audits provide the data necessary to predict when a component might need replacement, allowing you to schedule maintenance during planned shutdowns.

How Should You Manage Cooling and Thermal Conditions?

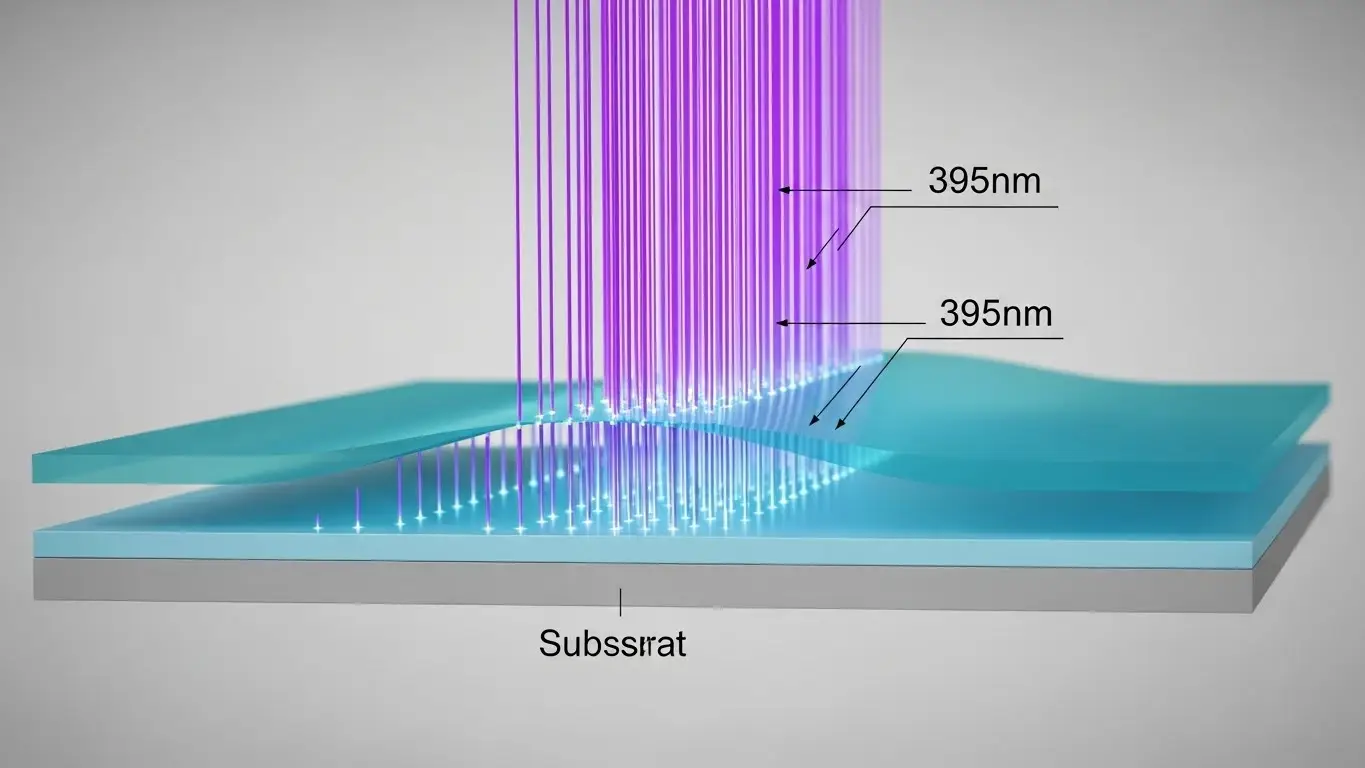

Managing cooling and thermal conditions involves ensuring that fans, filters, or water-cooling loops are functioning properly, free of obstruction, and matched to operating demands. You must clean or replace air intake filters regularly, as a clogged filter forces the system to run hotter, which directly reduces the UV intensity output of the diodes. For liquid-cooled systems, you should monitor the coolant level and clarity, ensuring that no biological growth or sediment is restricting the flow through the narrow channels of the lamp head. Maintaining a stable temperature is the only way to ensure the peak wavelength of your LEDs remains perfectly aligned with your photoinitiator's requirements.

What Performance Indicators Should You Monitor?

Key performance indicators to monitor include changes in intensity output, uniformity of the cured field, and any shifts in dose or exposure consistency. You will notice that if the intensity ($W/cm^2$) begins to drop, you may need to slow down your conveyor to maintain the required energy dose ($J/cm^2$). Tracking these numbers in a logbook allows you to see the "decay curve" of your LEDs over time, helping you plan for equipment upgrades or repairs well in advance. Significant shifts in uniformity often indicate that a specific LED module within the array is failing or that the internal optics have become misaligned.

What Common Problems Can Maintenance Help Prevent?

Consistent maintenance helps prevent problems such as overheating, loss of intensity, uneven curing, and unexpected system shutdowns. You can avoid "tacky" surface defects by ensuring your lenses are clean and your power levels are stable. Proper thermal management prevents the LED chips from reaching a "thermal runaway" state, which can permanently destroy an expensive array in a matter of minutes. By addressing small issues like a noisy fan or a slightly cloudy window early, you prevent them from cascading into major production failures that halt your entire manufacturing line.

How Does Maintenance Affect Operational Costs and Life Span?

Good maintenance practices can lower operational costs and extend system life by reducing stress on components and avoiding premature failures. You will find that an optimized and clean system requires less electrical power to achieve the same cure results as a dirty, struggling unit. While LEDs are rated for 20,000+ hours, this lifespan assumes they are kept within their ideal thermal and environmental windows. By investing a few minutes each day in maintenance, you maximize the return on your capital equipment investment and ensure that your cost-per-part remains low and predictable.

What Are the Key Takeaways for UV LED Curing System Maintenance?

Successful industrial curing is the result of keeping your equipment in its original, calibrated state through disciplined routine care. You get the most reliable results when you prioritize the cleanliness and cooling efficiency of your UV LED systems.

- Daily inspections of optics and cooling are your first line of defense against defects.

- Radiometer mapping is essential for detecting intensity drift and ensuring uniformity.

- Thermal stability directly dictates the longevity of your LED chips and the quality of your cure.

- Preventive tasks are significantly cheaper than reactive repairs and lost production time.

What System Specifications Influence Maintenance Needs?

Different hardware designs have different upkeep requirements. You can learn more about how UV LED curing system specs dictate your maintenance schedule.

How Do Cooling Systems Impact Maintenance?

Your upkeep routine changes depending on whether you use air or liquid. Compare the needs of water-cooled systems versus air-cooled units.

How Does Intensity Affect System Wear?

Driving your lamps at maximum power increases the need for thermal monitoring. Review how UV LED intensity levels impact your system's aging process.

How Does Dose Calculation Tie Into Ongoing System Checks?

Inconsistent dose delivery is often a sign of a maintenance issue. Learn how to calculate UV LED dose to help you verify your system's health.

How Is Output Uniformity Affected by System Health?

A dirty lens or a failing module creates uneven spots across your width. Explore why UV LED curing uniformity is a key maintenance indicator.

Why Does Lamp Temperature Matter for Maintenance?

Excess heat is the primary cause of LED failure. Read about how lamp temperature serves as the ultimate diagnostic tool for your equipment.

Final Thoughts on Maintenance Routine

Finalizing your maintenance checklist is a commitment to the long-term quality of your manufacturing output. While UV LED systems are remarkably robust, their performance is ultimately limited by how well you manage their operating environment and the cleanliness of their optical paths.

By treating these checklists as mandatory rather than optional, you empower your team to spot problems before they affect your customers. The most efficient production lines are those where the equipment is always ready, always clean, and always performing exactly as the technical data sheet promises.