Do UV LED Curing Systems Need Water Cooling?

In the design of an ultraviolet curing process, thermal management is as critical as the light output itself. While modern LED technology is significantly more efficient than traditional mercury lamps, it still generates a substantial amount of heat that must be removed to protect the diodes.

This guide answers the common question of whether UV LED curing systems need water cooling by examining the technical thresholds of different cooling strategies. By understanding how intensity and duty cycles influence heat generation, you can select a cooling method that ensures long-term stability and minimizes your operational maintenance costs.

Do UV LED Curing Systems Always Need Water Cooling?

UV LED curing systems do not always need water cooling because many low-to-moderate power systems are designed to operate effectively with air cooling. You will find that the necessity for liquid cooling is driven entirely by the power density of the LED array and the environment in which it operates.

If you are using a tool for intermittent assembly or low-speed production, the heat generated by the LEDs can often be dissipated through integrated fans and high-surface-area heat sinks. However, as the irradiance levels ($W/cm^2$) increase to meet the demands of high-speed manufacturing, the thermal load exceeds what air can effectively carry away, making liquid cooling a technical requirement.

Why Cooling Matters in UV LED Curing Systems

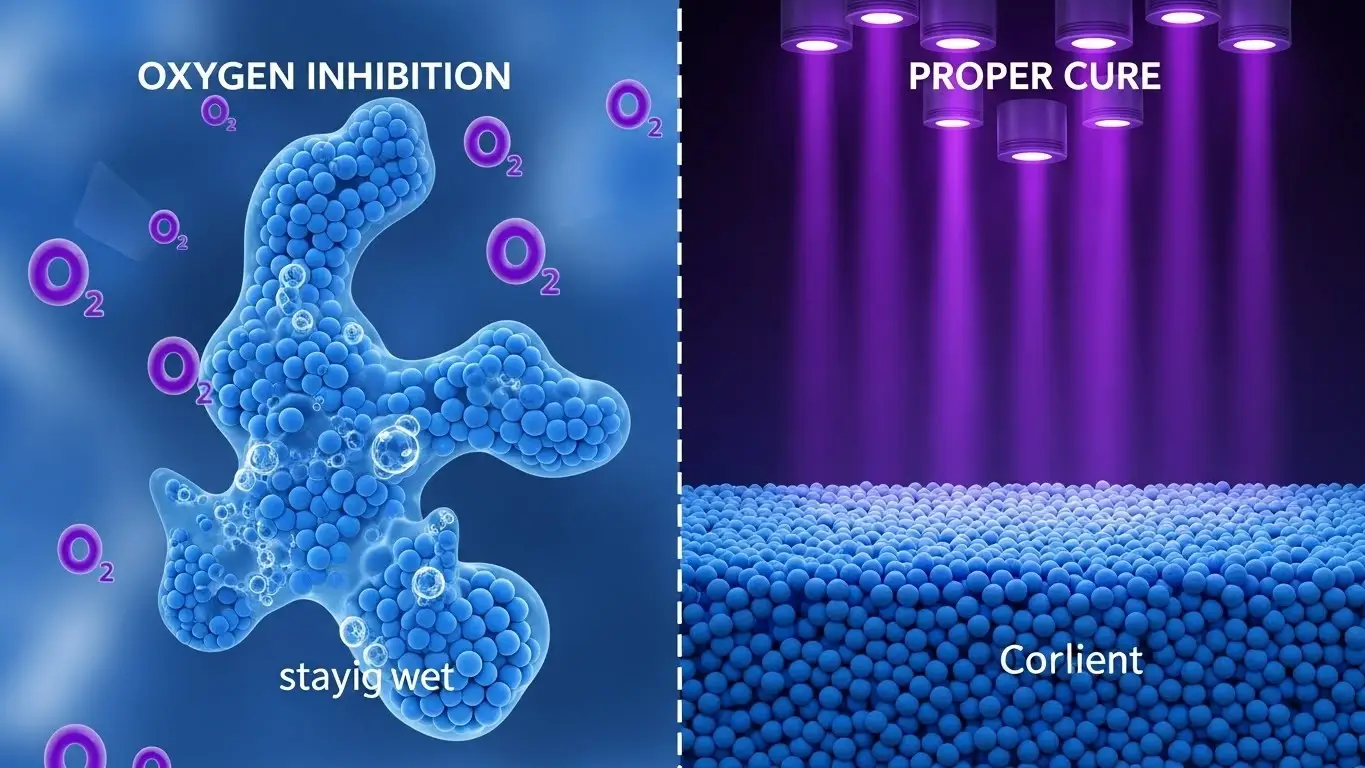

Cooling matters because excess heat can reduce UV LED output stability, shorten LED lifespan, and affect curing consistency. You should view an LED as a temperature-sensitive semiconductor; as the internal junction temperature rises, the efficiency of the light production drops.

This thermal decay means that an uncooled or poorly cooled lamp will lose intensity over the course of a production shift, leading to under-cured parts. Furthermore, excessive heat causes physical stress on the diode packaging and internal connections, which can lead to premature equipment failure. Proper heat dissipation is the only way to ensure that the ultraviolet dose remains identical from the first part of the day to the last.

When Air Cooling Is Usually Sufficient

Air cooling is usually sufficient for handheld lamps, spot curing systems, and intermittent-use applications with moderate UV output. You will notice that these systems are often self-contained, using internal fans to pull air across aluminum or copper fins attached to the LED board.

This method is ideal for manual workbenches, field repairs, or automated lines with significant "dwell time" between parts, allowing the lamp to cool down. Air cooling provides the benefit of a smaller footprint and lower initial cost, as you do not need to install an external chiller, hoses, or specialized coolant monitoring systems.

When Water Cooling Becomes Necessary

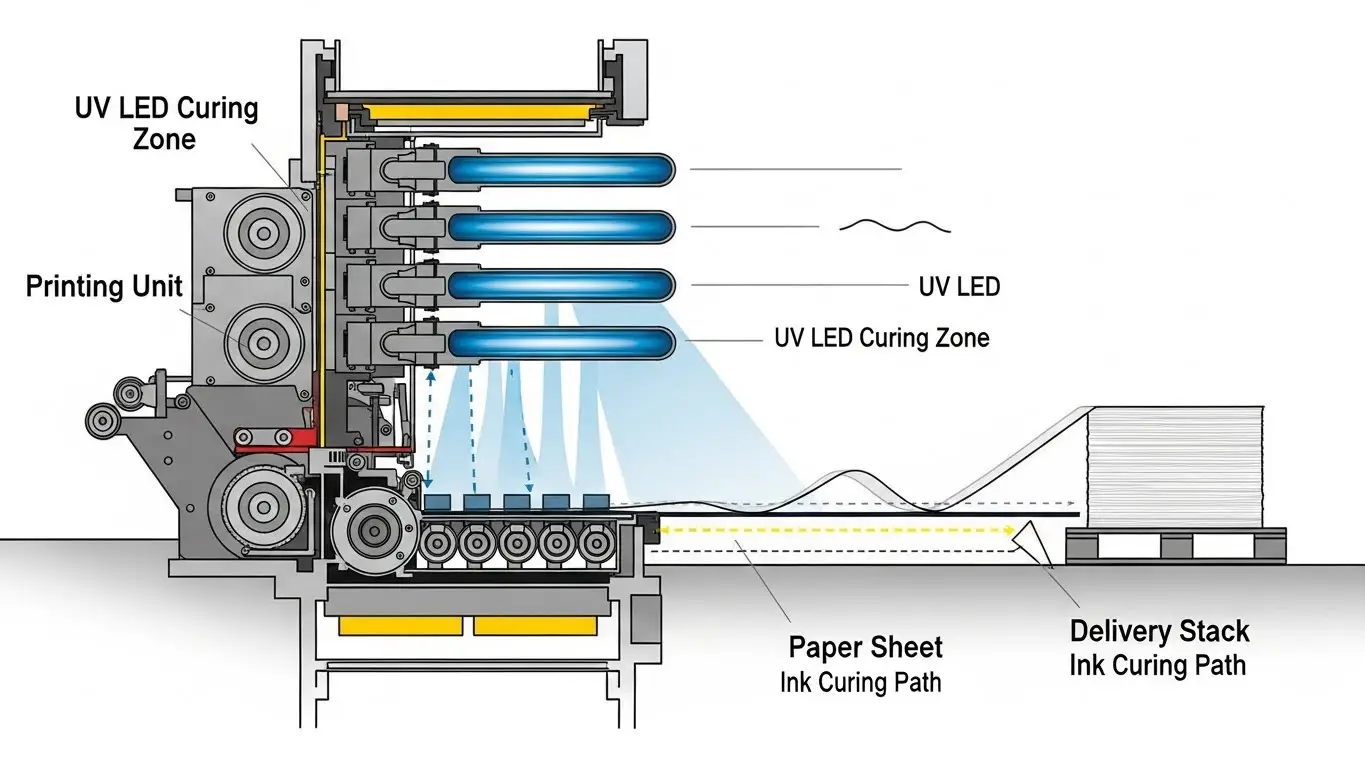

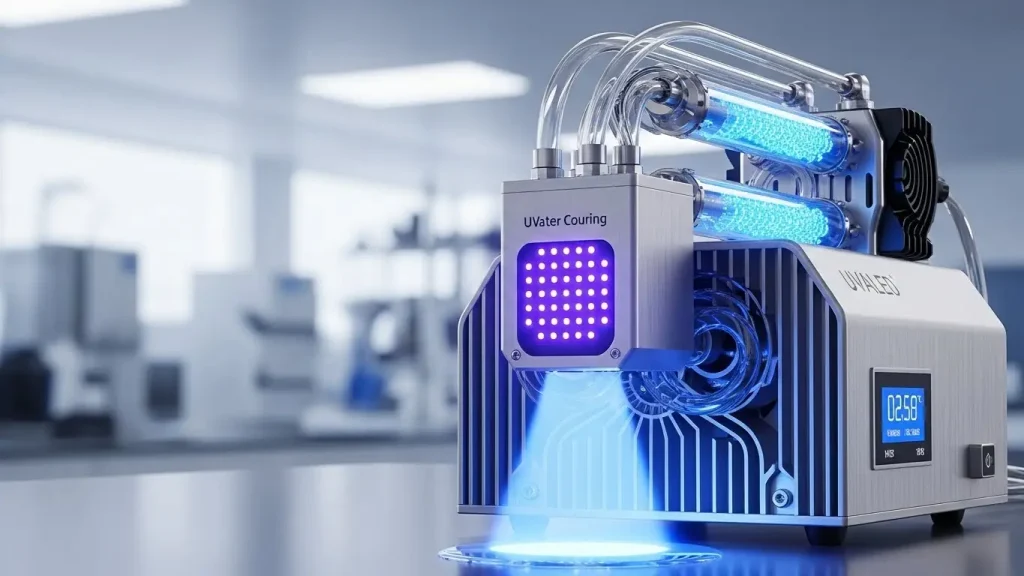

Water cooling becomes necessary when UV LED curing systems operate at high output levels, run continuously, or are integrated into high-throughput production environments. You should expect to use water cooling for any system exceeding 12–16 $W/cm^2$ of peak irradiance or for lines that run 24/7 without pauses.

Water is a much more effective heat transfer medium than air, allowing it to absorb and transport large amounts of thermal energy from a very small area. By circulating a chilled coolant directly behind the LED chips, you can maintain a very low and stable junction temperature. This stability is mandatory for high-speed printing, fiber coating, and other processes where even a 5% drop in UV output would compromise the product's quality.

How Cooling Choice Affects Performance and Maintenance

Cooling choice affects system performance, maintenance complexity, and installation requirements. You must balance the simplicity of air cooling against the high thermal capacity of water cooling when planning your facility.

- Air-Cooled: Requires clean ambient air and regular filter changes to prevent dust from clogging the heat sinks. If your factory is dusty or hot, air cooling efficiency will drop.

- Water-Cooled: Requires an external chiller, periodic coolant checks, and leak inspections. It offers a much higher "ceiling" for intensity and is unaffected by the ambient temperature of your factory floor.

- Installation: Air systems are often "plug-and-play," whereas water systems require plumbing and electrical integration for the chiller unit.

What Are the Key Takeaways on UV LED Cooling Requirements

UV LED curing systems may use air or water cooling depending on power level, duty cycle, and application demands. Selecting the right method is a matter of matching the cooling capacity to the heat generation of your specific curing task.

- Air cooling is the standard for portability and moderate industrial use.

- Water cooling is mandatory for high-power, continuous production lines.

- Thermal stability directly correlates to the consistency of your final cure quality.

- Environmental conditions like dust and ambient heat should dictate your final choice.

How Do UV LED Spot and Handheld Curing Systems Manage Heat?

How do UV LED spot and handheld curing systems handle heat during operation? Most UV LED spot and handheld curing tools utilize internal fans or passive metal heat sinks to keep the diodes within their safe operating range during manual assembly tasks.

How Do UV LED Spot Curing Systems Differ in Cooling Design?

How do UV LED spot curing systems vary in cooling approach based on output? You can find both air-cooled and water-cooled UV LED spot curing systems, with a specific UV LED spot curing system often being chosen based on the required irradiance and duty cycle.

How Do Handheld UV LED Curing Lamps Handle Thermal Load?

How do handheld UV LED curing lamps manage heat without water cooling? A handheld UV LED curing lamp is designed for portability, so it relies on efficient handheld lamp usage and internal airflow to prevent overheating during manual repair or assembly.

How Do Wavelength and Cure Time Affect Heat Generation?

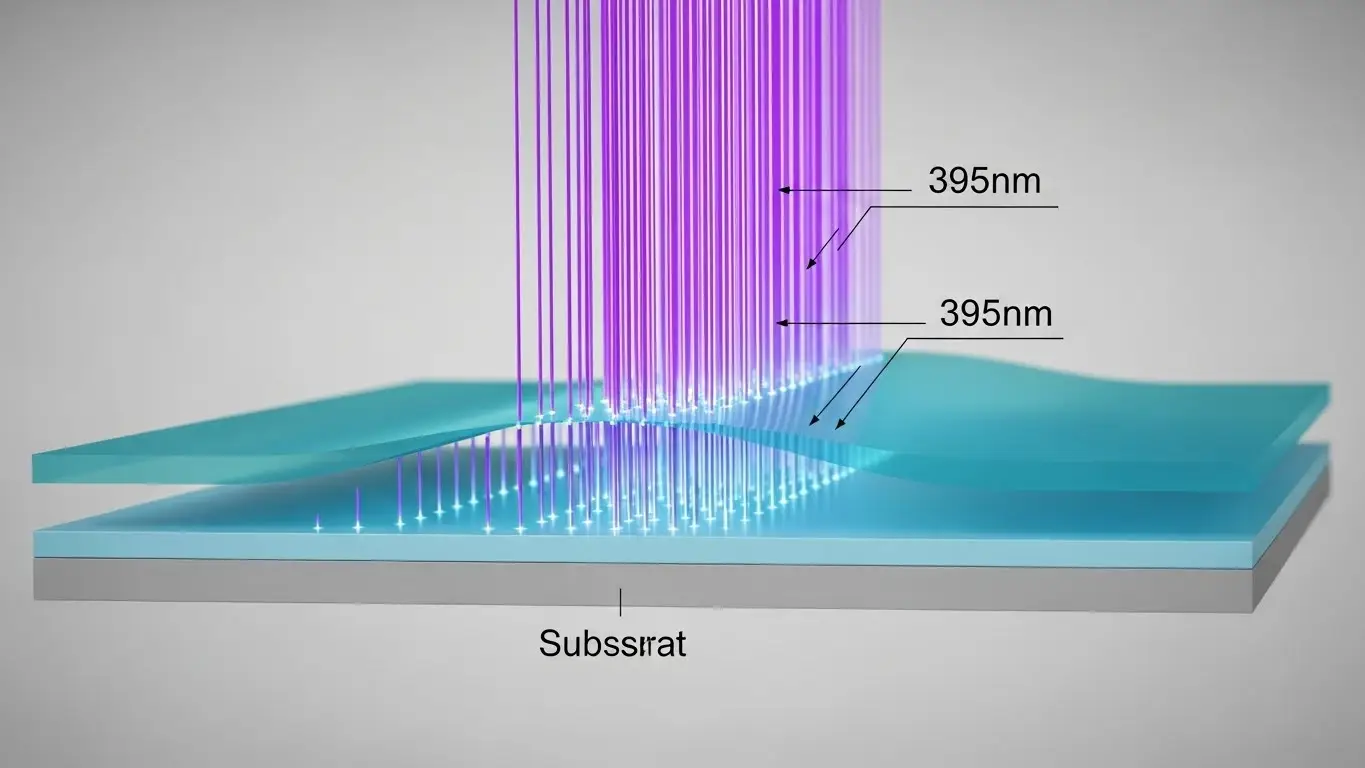

How do wavelength selection and exposure duration influence heat buildup? Choosing the wrong UV adhesive curing wavelengths or having an excessively long UV adhesive curing time can increase the thermal load on your system, requiring more robust cooling to prevent output decay.

Are Battery-Operated UV LED Curing Lights More Likely to Be Air-Cooled?

Do battery-operated UV LED curing lights typically rely on air cooling? Because they are built for mobility, a battery-operated UV LED curing light or other battery UV LED curing lights almost exclusively use air cooling to maintain their cordless profile.

Final Thoughts

Finalizing your cooling strategy is an investment in the longevity and predictability of your manufacturing line. While it is tempting to choose air cooling for its simplicity, you must ensure it can handle the maximum energy output your process requires. If you are pushing the limits of LED intensity to achieve faster line speeds, water cooling provides the thermal headroom necessary to prevent "thermal drift" and equipment failure. By aligning your cooling method with your system's power density and duty cycle, you create a stable environment where your ultraviolet chemistry can perform at its peak efficiency.