What is a UV LED Light Cabinet?

A UV LED light cabinet is a specialized cabinet fitted with ultraviolet LED lamps used to cure adhesives, coats, inks, and resins. These cabinets use UV LED curing modules in order to provide uniform radiation, which provides consistent UV LED radiation curing to a variety of industrial processes.

The main characteristics of the modern UV LED cabinets are:

- Adjustable Wavelength UV LED Curing: Multi-wavelength, if you want to match light output to a specific material absorption curve, multi-wavelength options are available.

- Even UV Distribution of Energy: Achieves uniform results and eliminates under-cure of coating.

- UV LED Cabinets thermal management: Water or air cooling as a means of keeping operation constant during the long-term runs.

- Modular UV LED Light System: It is expandable or reconfigurable to production requirements.

- Smart Control Interfaces: Automated UV curing cabinet systems and PLC-compatible systems to fully integrate into the production lines.

The latter characteristics render the UV LED light cabinet suitable in cases requiring high-precision UV LED curing, fast processing, and energy-saving.

Working of UV LED Light Cabinets

Polymer cross-linking with UV radiation is used to cure the material in a UV LED curing chamber. When the light of LED modules reaches the surface of coverage or glue, it initiates chemical reactions in hardening or solidifying the surface.

An extinguishing process of a UV LED cabinet is usually:

- UV modules based on LED: Provide specific wavelengths to apply to curing.

- Modular cabinet design: Facilitates the curing footprint.

- Thermal management: Maintains constant temperature in long operations.

- Evenly distributed UV energy: ensures all the parts are cured in equal measure, reducing defects.

In modular designs, manufacturers can obtain flexible UV LED curing lines that are compatible with diverse substrates that include electronics, plastics, metals, and medical-grade materials.

Benefits of UV LED Light Cabinets

- Energy Efficiency

Compared to the old mercury lamps, UV LED technology uses much less power and offers energy-saving UV LED light cabinet solutions without compromising on the speed of the curing process or product.

- Maximum Precision and Consistency

These cabinets can deliver a reliable production of UV curing and controlled UV intensity, and high-speed UV LED curing cycles with uniform results on all the parts.

- Scalable and Modular Design

Cabs are modular and can be extended and rearranged with cabinets of various LED curing units to suit various production needs.

- Flexible Integration

UV LED cabinets have automated UV curing cabinet configurations and intelligent controller interfaces, making it easy to incorporate the UV cabinets in production lines.

- Reduced Production Time

The high-intensity UV LED curing enables a reduction in the cycle time, which enhances throughput with quality.

- Durability and Reliability

Cabinets with UV LEDs have efficient thermal management that guarantees long service life and easy maintenance.

Technology UV LED Light Cabinets

The new UV light cabinets combine several new technologies to make them better:

- LED-Based UV Modules

LED modules offer instant switch-on / switch-off, adjustable wavelengths, and homogeneous energy distribution. This has the effect of providing UV LED curing free of defects on even heat-sensitive material.

- Adjustable Wavelength Cabinets

Most of the cabinets have adjustable wavelengths (365nm, 385nm, 395nm, 405nm) enabling them to match adhesives, inks, and coats to be cured as desired.

- Water-Cooled UV LED Cabinets

Water cooling will provide stable temperature, eliminate overheating, and provide stable UV LED system activity over extended periods when used in industry.

- UV LED Cabinet Hybrid Technology

Other systems are based on the integration of UV LEDs with additional curing methods to enhance the penetration and curing of thick or intricate parts.

UV LED Light Cabinets Uses

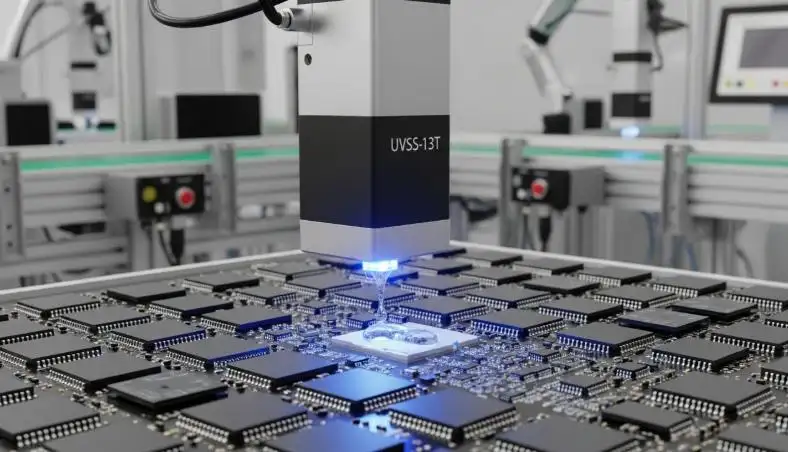

- Electronics Assembly

The best choice of UV LED curing is in the electronics assembly of PCBs, optical, and semiconductor parts. Their even distribution of light makes them cure UV LEDs without the problem of defects.

- Medical Devices

Medical-grade adhesives and coatings have the advantage of being cured by UV LED and offer consistent results without the need for excessive heat that can harm fragile parts.

- Automotive Coatings

The coating and adhesive used in automotive curing must be very consistent. UV LED curing cabinets provide high-quality adhesion and surface finish as a result of precise and regulated energy distribution.

- Printing and Packaging

UV LED cabinets can be used to cure using UV LED to print and package flexographic, screen, and inkjet. Large internal size and adjustable shelves allow the batch processing of various items.

- Optical Bonding

UV LED cabinets offer even UV LED curing of optical bonding, eliminating the thermal stress of sensitive materials on adhesives.

- 3D Printing

When making the photopolymer and resin 3D printing, the curing of the photopolymer is done by using UV LED cabinets that guarantee fast, safe, and quality production.

UV LED Curing Chamber CS300A

The CS300A UV LED curing chamber is also one of the most flexible ones, and it is used in printing as well as industrial applications.

Specifications:

- Internal Dimensions: 300 x 300 x 300 mm

- Outline Dimensions: 360 x 360 x 360 mm

- Operation: Door-activated door UV LED lamp control.

- Status Visible: Anti-UV leakage monitoring window.

Features:

- High Energy Density: Assures quick and effective curing.

- Multipurpose: Works with the different UV Lamps.

- Large Internal Size: They hold several or tall parts.

- Adjustable Shelves: Hardly fixed and can be adjusted to accommodate parts of different heights.

- Even Illumination: Reflective interior provides even lighting distribution.

The chamber aids in the precision curing of electronics, medical equipment, components that are printed components, and prototyping. It has a vertical design, adjustable shelves, which maximize interior volume and productivity, and ensure good quality curing is consistent.

Conclusion

UV LED light cabinet is an essential device in the contemporary industrial curing processes and an ideal combination of high accuracy UV LED curing, scalability by modules, energy conservation, and compatibility with automation. These cabinets have a dependable UV LED curing output, unwavering supply, and flawless results in electronics assembly and medical equipment, printing, optical bonding, and car paint treatments. Visit UVET.

- PREV: What is Precision Spot Curing?

- NEXT: Null