What is a UV LED module?

The UV LED module is emerging as the gold standard in the fast-paced industrial curing, sterilization, and precision use. These small modules also provide high-power UV applications, long life, and energy efficiency as opposed to the traditional UV lamps. These modules are changing the industries, whether it is curing adhesives, sterilizing water, or 3D printing. It is a small grouping of ultraviolet light-producing diodes, which are created to generate regulated UV wavelengths for a certain end. These modules are set at 365nm, 385nm, 395nm, or 405nm to control the required curing or sterilization effect.

Modules are solid-state UV lighting systems as opposed to mercury-based UV lamps. They are green, mercury-free, and have the benefit of on/off switching in a short time. This results in their suitability for industries that involve precision and speed.

Small UV LED Module | Large Life and High Power

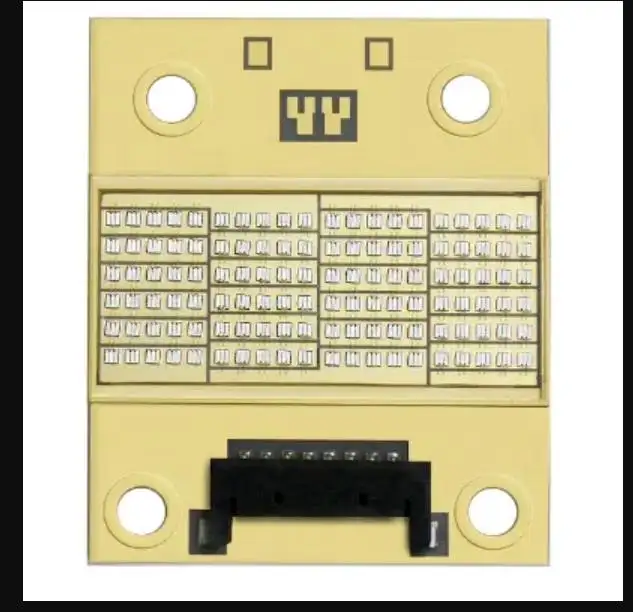

The COB LED UV Solution consists of 120 powerful LED chips bonded to a small metal core printed circuit board (MCPCB). This chip-on-board COB design is designed to offer excellent heat dissipation, UV stability, and longevity. Having a peak wavelength of 365nm, it provides high-intensity ultraviolet light that is uniform and is highly applicable in a variety of industrial, medical, and scientific uses. The COB is relatively small yet mighty, and it is the best option in case a business wants to use efficient and eco-friendly UV lighting. The most popular features of the COB LED UV solution are light-producing diodes that can produce various colors, such as red, blue, green, yellow, and pink, to mention a few:

• High UV Intensity- Provides stable and potent UV.

• Chip-on-Board Design - 120 UV LED chips fitted together into one chip.

• Superior Thermal Management - developed on MCPCB to maintain consistency.

• Long Service Life -It serves in 20,000-30,000+ hours.

• Eco-Friendly -Free of mercury, energy saving, and environmentally safe.

• Compact Size - Smaller size with no loss in power.

Advantages of the module

COB LED UV Solution is designed to produce a high density of energy in a small area. This solution has the following advantages:

• Equal distribution of UV light to achieve consistency.

• Poor thermal resistance, no overheating.

• High efficiency, which lowers the cost of operation.

Its modular UV curing solution design allows it to be installed with industrial curing systems, UV exposure devices, or medical sterilization devices.

Applications

The UV LED technology is increasing in industries. Some of the most important applications are:

• UV LED Printing Module: Ink curing in digital printers.

• 3D printing Module: Accurate resin hardening.

• UV LED Water sterilization module: Drinking water disinfection.

• UV Module PCB Exposure: Precise PCB exposure in electronics production.

• UV LED Resin Curing: Jewelry, electronics, and coating.

• Large-scale curing of adhesives and coatings: Industrial UV LED Systems.

Benefits compared to the conventional UV Lamps

The advantages of replacing mercury UV lamps with solid-state UV LED lighting are:

• Greener: No mercury or toxics.

• Precision: Narrowband UV light emission to obtain curing.

• Durability: Shock-absorbing and strong when used in tough conditions.

• Economical: Prolonged life saves on replacement expenses.

- Energy Savings: Efficiency can be converted into reduced costs of operation.

• Integration: simple to integrate into modular UV curing solutions.

Selecting the Optimal UV LED Module

In choosing an UV LED curing module, take into account:

1. Wavelength Needs: Match chemistry (e.g., 365nm adhesives, 395nm printing).

2. Intensity Levels: A Thick coating is more suited to high-intensity modules.

3. Cooling System: Water-cooled modules are more durable in the heavy-use environment.

4. Module Size: Compact modules are used in lab setups; wide-area modules are used in production lines.

5. Supplier Reliability: Find a cost-effective supplier of modules and of proven quality.

A Buyer's Guide

When you intend to go out shopping with a manufacturer of custom UV LED module, inquires:

• What are the wavelengths you provide?

• Do you integrate UV LED?

• How long do your modules take to average life?

• Are you capable of giving thermal management data?

How to Select the Appropriate COB LED UV Solution?

1. Identify Application, curing, sterilization, printing, or inspection.

2. Wavelength Choice Use 365nm to cure, 265-280nm to sterilize, 395-405nm to cure in general.

3. Check Output Power: Check intensity with curing or disinfection requirements.

4. Test Thermal Control- Test that the module is well cooled.

5. Establish Power Supply Compatibility- Voltage/ current should be in line with the driver.

6. Take into account the Installation Requirements, module size, shape, and IP rating of the environment.

7. Check Lifestyle/Certifications - Find certified life expectancy and safety.

UV LED Module Trends in the Industry

The UV LED market in the world will increase by more than 20 percent within the next five years. Drivers include:

Environmental Regulations: Push away mercury lamps.

Industrial Requirement: Expansion in printing, electronics, and coatings.

Healthcare: Increasing the need for UV sterilization modules.

03D printing boom, Precision UV curing additive manufacturing.

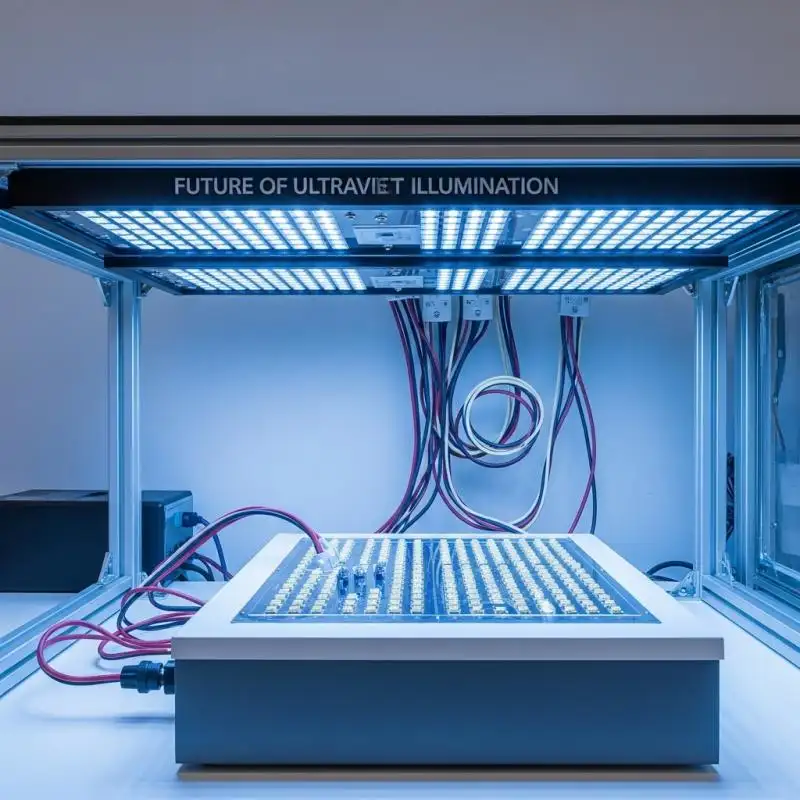

The future of UV LED Module Technology

The UV LED arrays of tomorrow will be smaller, stronger, and cheaper. The optimization of curing efficiency has already been tested with the AI-controlled UV exposure systems. The thermal management, optics, and integration will keep on changing. The future will be modular UV curing solutions - scalable, flexible, and environmentally friendly.

Conclusion

The UV LED module is not only a source of light. It forms the backbone of the contemporary curing, sterilisation, and exposure technologies. These modules provide efficiency, durability, and sustainability in printing and adhesives, healthcare, and water purification. With the selection of the appropriate high module, the businesses can save money, comply with environmental requirements, and produce superior outcomes. To see the innovative modules supporting your industry, go to UVET.

- PREV: Brief introduction

- NEXT: What Is Instant-On LED UV?