What Is UV LED Printing?

One process that utilizes UV light-emitting diodes (LEDs) is UV LED printing, in which UV-sensitive inks are instantaneously cured by Ultraviolet light (UV) as the printing process proceeds. This is an alternative to traditional thermal curing, as this technique involves focused UV light and not heat, and materials are, in fact, not damaged.

The major benefits of printing machines are:

- Direct curing without warming up.

- High-resolution printing

- Energy efficiency

- Minimal heat generation

- Long operational lifespan

UV LED inkjet printing and UV LED digital printing have enabled industries to use UV printing precision in many substrates, both flat and 3D. This design has made printing technology suitable for packaging, signage, electronics, textiles, promotional objects, and medical equipment.

The Technology behind UV LED Printing

The main component in UV LED printing systems is the UV LED cure process, where a controlled wavelength is used to cure UV inks. The most popular UV LED wavelengths used in printing are:

365nm UV LED: Adhesive and fine details. Deep curing.

385nm UV LED: Coating, labeling, printing, and balancing curing.

395nm UV LED: It is the best choice when it comes to resin, 3D printing, and manufacturing in general.

405nm UV LED: Curing of temperature-sensitive materials.

UV LED print heads are made with high-performance to produce even light distribution, and UV LED optical design, UV LED thermal management, and UV LED driver circuitry are designed to ensure stable and efficient operation. The product is high-resolution printing, accurate UV printing, and proper curing on all materials.

UV LED Printing Technology

Our solutions are highly flexible with a wide range of industrial, commercial, and creative applications:

Packaging

Industrial labels, custom packaging, and branding of products are also commonly made using UV LED printers. The inks cure fast with an adjustable UV intensity and a wavelength adjustment that produces a good finish and rich coloring.

Electronics

UV LED printer electronics enable a fine application on circuit boards and electronics. The technology will make sure that there is minimal heat effect and high curing efficiency.

Signage

From big exterior signs to small interior signage, the UV LED printer of signage will provide fast printing with even coverage, sharp lines, and high adhesion.

Promotional Items

The use of UV LED inkjet printing is perfect for customized promotional items, such as pens, mugs, and electronic accessories. The UV LED digital printing system provides a good consistency in the results of different materials.

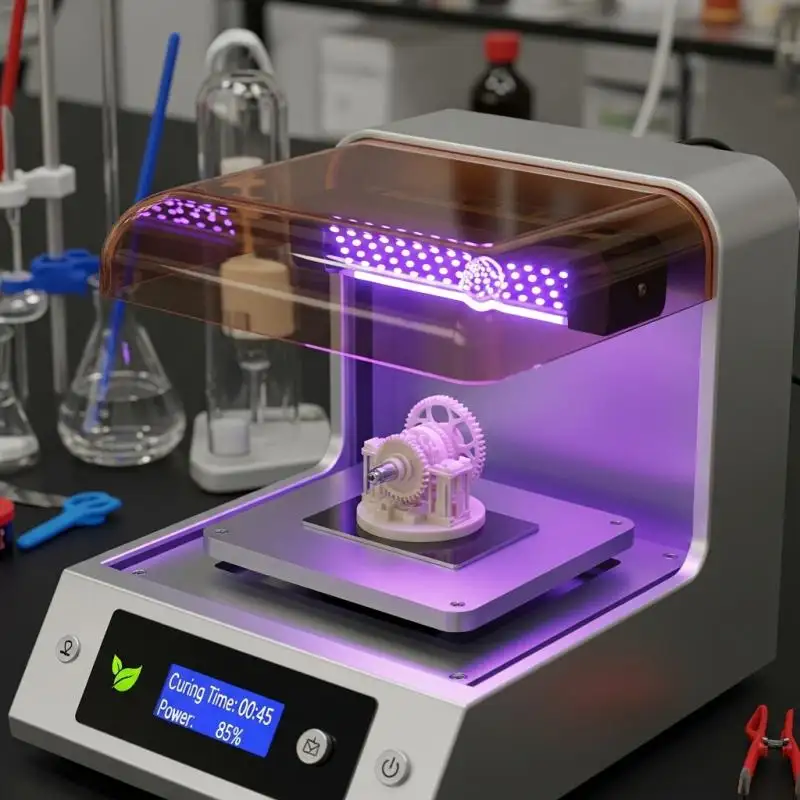

3D Printing

The fact that the printing technology is compatible with the 3D printing application allows quick curing of resins, which takes less time to print than high-resolution results.

Medical Devices

The technology of UV LED printing medical device printing is designed to provide clean, precise, and contamination-free printing, and meets the strict requirements of the medical device industry.

The UV LED System of UVET Printing: Best-in-Print UV LED System

The UV LED System of 650x20mm series of UVET provides up to 12W/cm2 of UV intensity, providing a high rate of reliable curing of a variety of UV inks and materials. It is very flexible and has high accuracy in design, and is used in flatbed inkjet printing systems.

Key Features

Higher curing efficiency: Provides as much as 12W/cm2, and provides a fast and even curing rate.

Flexible wavelengths: 365nm, 385nm, 395nm, and 405nm are available with various materials.

Adjustable controls: UV intensity and exposure time can be easily adjusted to achieve specific results.

Flexibility in terms of coverage: The size of 650x20 mm covers a large area, thus providing a consistent curing across large prints.

Why Choose UVET's System?

Energy-saving: Uses less power, yet it is highly performing.

Low intensity heat: Safeguards temperature-sensitive media.

3D printable: Multimedia UV printing.

Easy to use: Can be integrated with the current printing systems.

Trustworthy quality curing: Repeatability in small and large formats.

Having the capability of printing using UV LED, the system guarantees fast production, good quality prints, and low costs of operation.

The advantages of UV LED Printing Systems

Printing machines based on UV LED have several benefits over the older models:

Instant Curing

UV LEDs cure inks immediately, therefore, eliminating delays that are created by conventional bulbs.

High-Resolution Printing

Accurate UV LED print heads allow print details even on complicated surfaces.

Energy Efficiency

UV printing consumes less energy and gives maximum performance, especially when powered by high power.

Minimal Heat Impact

Non-damaging to heat-sensitive substrates.

Long Operational Lifespan

UV LED modules have an extended lifespan of thousands of hours, lowering the maintenance and operation expenses.

Technical Requirements for Best Performance

In determining a UV LED printing system, the following are technical factors to be considered:

Printing wavelength: Adjust UV output to ink and paper.

UV intensity control: Regulate energy and curing speed.

Design of print heads: Uniform coverage and resolution.

Thermal control: avoid excessive heating and increase the life of the LEDs.

Driver circuitry: Stable performance.

Module size and optical system: Fit system to workflow requirements

Our solutions are highly efficient, precise, and reliable by tuning these parameters to the optimum.

State of the Art Manufacturing Applications

The solutions of industrial printing fit:

Fast assembly lines: Boost the volume with no compromise on quality.

Multi-material printing: Plastic, metals, ceramics, and composites.

Custom packaging: Special machines to meet brand-specific needs.

Precision: Electronics, optical components, and medical devices.

UV LED flatbed printing systems and custom UV LED printing systems guarantee scaled printing systems for both small and large-scale operations.

Future of UV LED Printing

Our systems that are highly efficient in energy usage and can be customized have the future of printing. Industries can attain: with innovations of UV LED flatbed printers, UV LED digital printing, and UV LED inkjet systems.

- Reduced operational costs

- Faster production times

- Sustainable manufacturing

- Stable quality production.

Firms such as UVET are at the forefront of this change, and they are providing high-quality UV printing, industrial systems, and high-speed UV LED printers that use less power.

Conclusion

The printing industry is changing its face, and UV LED printing is one of the companies that is changing the printing sector by providing faster curing, high resolution, energy-saving, and environmentally friendly operation. The UV LED System of Printing (650x20 mm series) by UVET is an example of the novel technology, which features 12W/cm2 of UV intensity, adjustable wavelengths (365-405nm), adjustable UV intensity, and an extensive coverage to provide the best performance. The combination of these systems would help manufacturers increase the efficiency of production, assure high consistency, and save energy.