UV LED Spot Curing: Fast, Precise & Efficient Curing Solutions

Enhancing Precision and Productivity in Modern Manufacturing

Considerations for diagnostics and automated manufacturing systems require speed, accuracy, and dependability. The medical device assembly, electronics bonding, and automotive part manufacturing industries have been early adopters of UV LED spot curing technologies. For those businesses wishing to obtain the advantages of energy efficiency and reduced environmental impact, UV LED curing will meet those needs.

Explaining LED UV Spot Curing

LED Lamps in Photo-Curing Units

This forms the structure of the handout concerning curing in light-emitting diodes. The blue light LEDs fitted in the photo curing head are helpful for quick and gentle curing of the material that is placed on the rotary table, which can be cured in stages. Precision sculpting of complex shapes can be achieved quite rapidly with laser beams of specific wavelengths focused on carved resin, and sensitive surfaces are not damaged because the heat produced is non-excessive.

Complete and Soft UV Curing Thermoforming

Working in teams with the basic photo curing machines, assisted surgeons to do the dental extractions and retentively and operatively set and cure them in a much more rapid fashion. The lasers employ LEDs, which lead to the curing of chloroplasts, which generate thermal effects on the neighbouring tooth, which leads to overheating the structure. Soft start mode is the level of laser incision above the peri-oral Nano capillaries from which jet streams emanate from the teeth. This leads to cavity creation being soft and highly accurate. It was achieved the refined hydrodynamic profile of the tooth was achieved while increasing the look with a surgical polish over the prosthesis.

Center of Interest: Health and the Environment

The UV LED Spot Curing System has surpassed previous model UV Lamps because of several features. Apart from minimal damage during curing, ozone emission is at near-negligible levels. Even the most delicate modern industrial components receive gentler care due to the curing process's gentleness.

Furthermore, the system can be equipped with fiber-optic tubing of different diameters, as well as switched between automatic and manual modes. To meet industry standards, the system has high-power UV LEDs that are capable of instantaneous on-off transitions to save radiant energy at the lens fibers.

Ecologically Beneficial and for the Conservation of Energy

Companies looking to improve their operations and profit margins will find UV LED Curing Systems advantageous, considering the low energy consumption as well as the absence of ozone, mercury, and other unfit waste materials. This has the benefit of reducing costs, but also lowers the company’s carbon footprint.

Precision curing is a restorative type of curing that applies curing only to specific areas, allowing greater detail than general curing. This is critical for smaller parts or even complex assemblies. Cross UV curing of fiber optics or even micro assembling is an example.

UV LEDs perform the same functions and, like other types of LEDs, accomplish them more economically than traditional UV lamps, thereby saving on maintenance and downtime due to long operational life. Also, their claimed dependability in achieving consistent output throughout a UV cure cycle supports these claims.

Considerations for the Selection Criteria for the Spot UV LED Curing System

The following suggestions are proposed as an addition to the design of a new Spot UV LED Curing System with specific criteria in mind. These particular pointers require special attention:

• Information Target Wavelengths: The curing wavelengths for the meshed products recorded in the Product datasheets shall be appended to fit the adhesive or resin used.

• Temperature: There is a need for moderation of power levels regarding other sensitive materials that incur excess heat.

• Production milestones must be met: The milestones for a system’s changeable parameters must be met at the expected rate of the production process that is being analyzed.

• System Dimensional Considerations: Handy devices become invaluable for some Handheld tasks for small-scale jobs.

• Results of Strenuous Work: Based on the enduring environment’s task loads and conditions, select air-cooled or water-cooled systems appropriate for the operational environment.

What Contemporary Methods of Spot UV LED Curing From the Conventional Methods of UV Curing?

Spot UV curing is a more recent development that builds on the previous methods of UV curing. Traditional curing UV systems incorporate mercury vapour lamps, which emit UV radiation at random, meaning it will be harmful and useful light at the same time. That serves the purpose of blasting UV to harmful, and useful, to fundamental parts of mercury UV-based vapour lamps. There is no such issue with LED spot curing systems. The diodes in LED spot curing systems yield light at the curing wavelengths of interest (365 nm, 395 nm, 405 nm), which permits effective curing of materials.

Going back to the advantages of UV LED Spot Curing Devices on the energy efficiency side, unlike traditional LED systems, mercury lamps use far more energy, operate at a higher temperature, and have a shorter functional life. The use of medical devices, electronics, and bonding requires less energy to form and does not overheat to the extent of protecting materials that are used to seal off sensitive parts.

What are the Benefits of Choosing UV LED Spot Curing?

As a result of its acceleration in processing duration, the technology is made more advanced in eco-friendliness. It can be found in medical assembly, automotive sensor bonding, and even 3D printing because UV spot LED curing is done at low temperatures and rapidly.

Such systems can heal with almost surgical precision and accomplish it with unparalleled effectiveness, which means great utility for the intended purpose.

The Technologies Innovations include the design of sophisticated systems for curing with UV LED, including systems for ventilation for industrial processes that are solar-powered and of high precision. Such systems improve productivity and aid in the frugal preservation of resources.

Conclusion

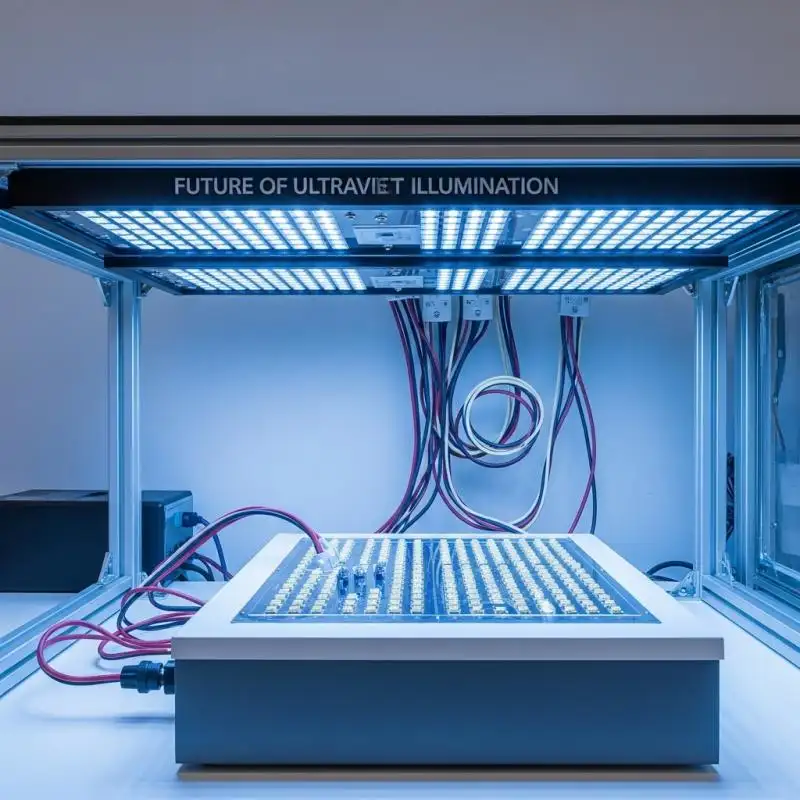

The UV LED curing System offers a powerful solution for wide area ultraviolet curing of UV-exposed materials. It offers high-accuracy focusable LED technology, which yields high-intensity UV radiation over a broad surface area, which is preferred in complex production lines and accurate fabrication processes.