UV LED Spot Curing: Accuracy and a high level of industrial uses

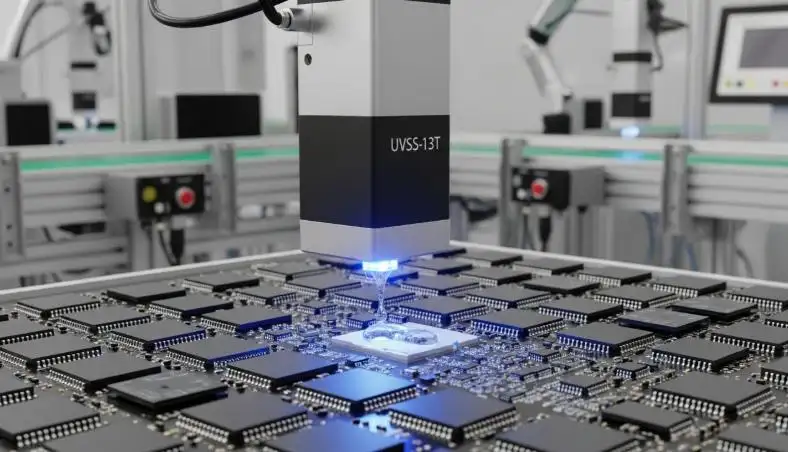

- Precision, speed, and efficiency are the main factors required in the current fast-paced manufacturing world as a way of staying competitive. UV LED spot curing is also one of the technologies that has revolutionized the process in industries. In contrast to the conventional methods of UV curing, LED UV spot curing provides focalized, high-intensity light, which provides rapid, accurate, and efficient energy-saving polymerization.

- The UV spot curing technology has transformed the electronics industry, medical devices, optics, and printing into new industries with controlled UV curing energy and lower operational costs, and reliability in production. UV spot curing system has enabled the manufacturer to have high performance with less energy use and little heat effect.

How to use UV LED Spot Curing?

UV LED spot-curing is a technique that involves using high-intensity ultraviolet light to cure adhesives, coatings, inks, and resins in a specific spot. In contrast to traditional UV lamps that use mercury, UV LED spot curing systems offer energy-efficient curing with low heat that remains consistent, eliminating thermal damage to delicate materials.

The advantages of UV spot curing technology are:

- Curing of sensitive parts with accuracy.

- Quick LED spot curing with more production cycles.

- UV LED curing is energy-efficient to lower the operational costs.

- Local UV curing to curb excessive exposure.

It provides high repeatability and consistent performance between production batches by providing consistent UV light distribution and regulating the energy curing.

Benefits of UV LED Spot Curing Systems

- Precision and Flexibility

The accurate UV spot curing method enables manufacturers to focus on the area when using high-intensity UV LED curing. This technology has made sure that curing adhesives in microelectronics and surface coating on optics is done accurately and does not have any influence on the surrounding materials.

- Rapid and Low-Heat Operation

It refers to low-heat levels to reduce thermal stress on thermal-sensitive components. Combined with quick UV LED spot curing, production cycles are also sped up, yet with a high-quality output.

- Energy Conservation and Sustainability

It consumes less energy than the normal mercury UV systems. By having eco-friendly UV spot curing and low-power UV spot curing, the manufacturers can use sustainable UV spot curing solutions that can adhere to the current environmental standards.

- Consistency and Reliability

The state-of-the-art UV LED curing modules and UV LED arrays used in spot curing are used to provide consistent light intensity and regulated curing energy. This consistency is imperative in other applications, such as electronics and health tools, where consistency in curing is an important requirement.

UV LED Industry Uses in Curing

- Adhesive UV LED Spot Curing

UV spot curing of adhesives is applied in electronics assembly, optics, and medical equipment. The process can achieve rapid and precise bonding of parts, as well as avoiding heat deformation.

- Coating and ink UV LED Spot Curing

Protective Coating coatings UV-sensitive inks, since UV LED curing of coatings offers uniform hardening and enhanced durability. On the same note, LED spot curing of inks assures clean, bright prints which have uniform adhesion.

- UV LED Spot Curing for Resins

Precision LED spot curing is needed in resins that are used in 3D printing, optical components, and coatings. When using controlled-energy spot curing, the manufacturers can obtain uniform polymerization and reduce defects.

- Electronic-UV LED Spot Curing

This method of encapsulation, conformal coating, and micro-assembly works in electronics manufacturing. The fast spot curing rate allows a reduction of time taken in manufacturing and still preserves the component.

- Ultraviolet LED Curing in Medical Equipment

In medical equipment, UV spot curing is used to offer safe, clean, and reliable bonding of delicate components like the catheters and diagnostic housings. The fact that it is low-heat spot curing eliminates the possibility of thermal damage to patients, as well as the product.

- UV LED Spot Curing in Optics and Printing

This curing in printing enhances the bond strength and rate of cure of ink, and UV spot curing of optics is required to achieve adherence and a higher curing rate of lenses and filters.

Technological Analysis of UV LED Spot Curing

- Intensive and Energy-saving LED Output

The UV LED spot curing is a high-intensity type of lighting used to increase the amount of light in a specific area. In combination with using energy-efficient UV spot curing, manufacturers will be able to save energy and, at the same time, attain the best curing depth and consistency.

- Maximized Exposure and Equalized Level of Light

Precision UV spot curing processes use a careful control of optimized exposure time and a uniform distribution of UV light to give consistent results on complex surfaces.

- Controlled-Energy Curing and Low-Heat Curing

It is also appropriate in temperature-sensitive components in electronic and medical devices because of advanced low-heat spot curing systems and controlled-energy spot curing that ensure that the material is not damaged.

Industrial Advantages

- Electronics: Quality bonding, sealing, and micro-assembly.

- Medical Devices: Catheter and diagnostic housing safe bonding.

- Optoelectronics: Mounts and fixes filters, sensors, and lenses.

The device provides a stable UV output, which provides precise spot curing of detailed surfaces and is thus suitable for the production processes that need consistency.

Handheld UV LED Spot Curing Solutions

In the case of portable applications, handheld LED spot curing devices offer flexibility, but without affecting performance. Features include:

- Mobility rechargeable operation.

- Several UV wavelengths (365nm, 385nm, 395nm, 405nm).

- Spot or wide-area spot curing optical lenses are interchangeable.

- Reduced the temperature power of temperature-sensitive elements.

These smaller instruments find wide application in field repairs, assembly of small components, and precision curing in a lab, and are commonly used to supplement larger bench-top or automated systems.

Conclusion

UV LED spot curing is revolutionizing the processes in industries because it is a combination of precision, efficiency, and sustainability. Whether it is a high-intensity LED array, small-scale UV LED curing devices, or any other application, modern technology guarantees fast, low-heat, and energy-saving polymerization. Through investment in professional UV LED curing systems and professional suppliers such as UVET, industries will improve productivity and save on energy usage, and adopt greener and sustainable manufacturing methods.

- PREV: What is Precision Spot Curing?

- NEXT: Null