What Is a UV LED Spot Curing System?

In precision manufacturing, the ability to deliver high-intensity light to a concentrated point is essential for localized bonding and assembly. While large-scale curing systems treat entire surfaces, a UV LED spot curing system provides the surgical accuracy needed for intricate components.

This guide defines these systems, explores their operational mechanics, and offers practical guidance on wavelength selection and safety. By understanding the technical parameters of spot curing, process engineers can achieve faster cycle times and superior bond strength in even the most challenging manual or automated applications.

What Is a UV LED Spot Curing System?

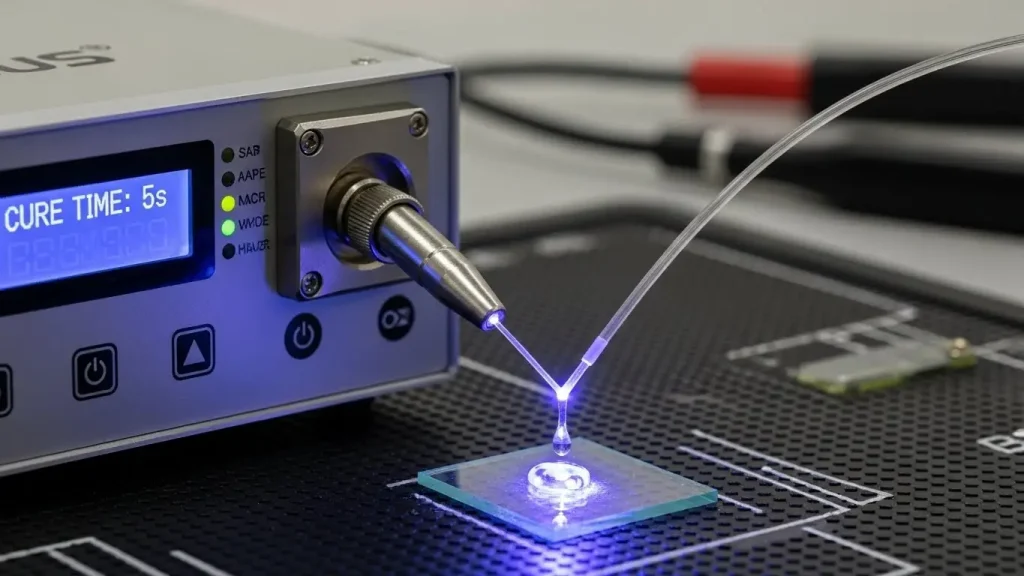

A UV LED spot curing system is a focused ultraviolet light system designed to deliver controlled UV energy to specific small areas for curing adhesives, coatings, and other materials. You will find that these systems typically consist of a controller unit and one or more LED heads or light guides that concentrate the beam into a targeted zone.

Unlike flood systems, a spot curing system provides a high-intensity "dot" of light, often as small as 3 mm in diameter. This allows you to target a single bond line on a circuit board or a medical device without exposing surrounding heat-sensitive parts to radiation. These systems are common in micro-electronics, optics assembly, and precision medical manufacturing.

How Does a UV LED Spot Curing System Work?

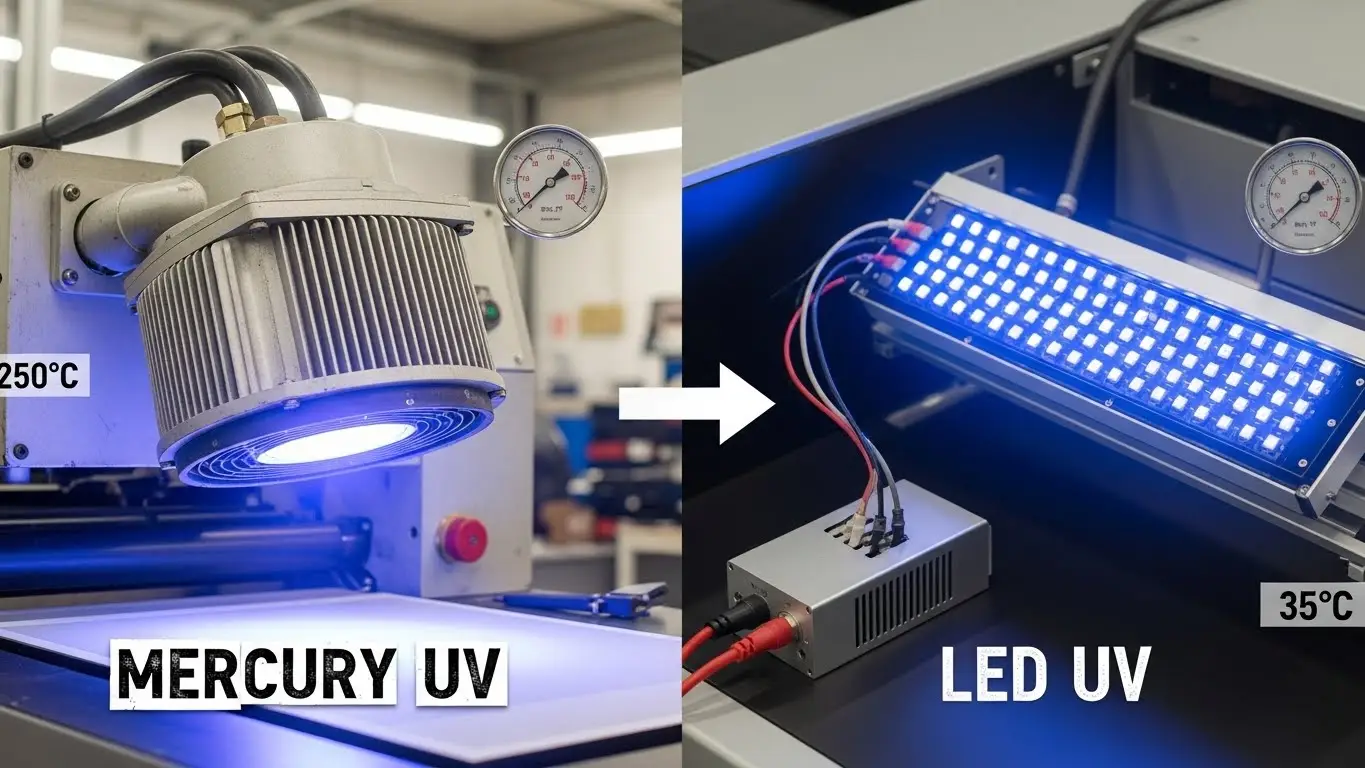

A UV LED spot curing system works by generating ultraviolet light at specific wavelengths that activate photoinitiators in adhesives and coatings to initiate polymerization. When the LED is powered, it emits a narrow band of UV light that passes through specialized optics or liquid light guides to focus the photons into a high-intensity spot.

Once these photons strike the liquid adhesive, they trigger the photoinitiators, causing a rapid chemical cross-linking that turns the liquid into a solid polymer within seconds. Because LEDs emit very little infrared heat, the process remains cool, preventing the warping or degradation of plastic substrates or delicate electronic circuits.

When Should You Use a Spot Curing System Instead of Other Options?

A spot curing system should be used when precise, small-area curing is needed and larger flood or conveyor systems are unnecessary or impractical. You will find these tools indispensable for manual assembly tasks where an operator must hold parts in place while the bond sets.

They are also ideal for "tacking" components before they move to a secondary curing stage or for making small repairs in high-value assemblies. If your part is large but the actual bond area is tiny, a spot system is far more energy-efficient and cost-effective than a wide-area flood lamp, as it concentrates all available energy only on the functional bond site.

How Do Wavelength and Adhesive Chemistry Influence Spot Curing?

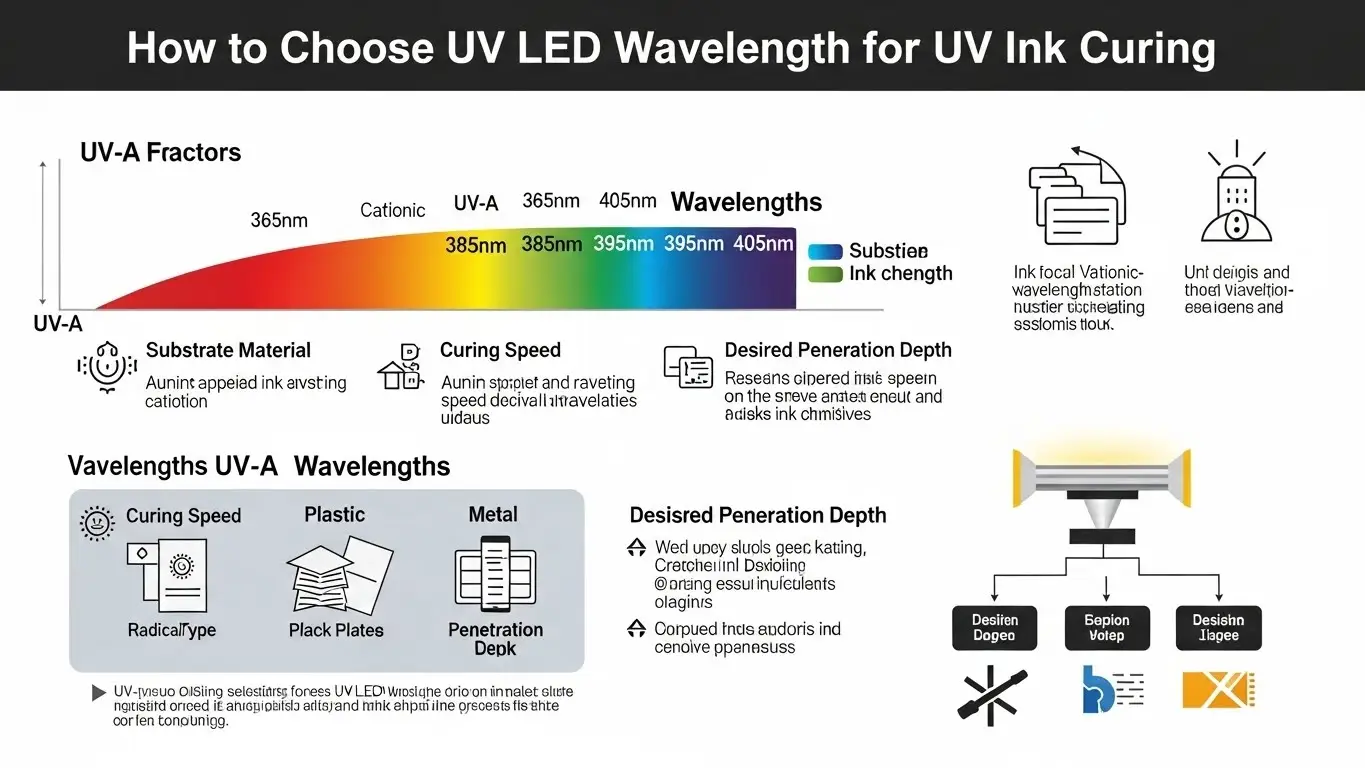

The wavelength output of a UV LED spot curing system must match the photoinitiator absorption profile of the adhesive for effective cure. You should always verify whether your resin reacts best to 365 nm, 385 nm, or 395 nm, as LEDs emit light in a very narrow spectral range compared to mercury lamps.

If you attempt to cure a 365 nm adhesive with a 395 nm lamp, the photoinitiators may not activate, leading to an incomplete cure or a bond that lacks structural integrity. Correct wavelength matching ensures that the ultraviolet energy is fully absorbed, leading to a deep, thorough cure through the entire thickness of the material without leaving liquid resin at the interface.

What Factors Affect Cure Time With a Spot Curing System?

Cure time with a UV LED spot curing system depends on the adhesive formulation, light intensity, wavelength, and distance from the surface. You will notice that as the distance between the spot lamp and the adhesive increases, the intensity drops significantly, which necessitates a longer exposure time to reach the required dose.

Thicker layers of adhesive or those containing dark pigments also require more time for the photons to penetrate to the base of the bond. To optimize throughput, you should calibrate your system to deliver the highest intensity possible at the closest safe working distance while using a wavelength that aligns perfectly with your specific chemistry.

What Practical Tips Improve Use of Spot Curing Systems?

Practical use of a UV LED spot curing system requires consistent positioning, controlled exposure, and awareness of material behavior. You can ensure repeatability in your process by following these technical guidelines:

- Use Fixturing: Utilize mechanical jigs to keep the spot lamp at a fixed height and angle for every part processed.

- Monitor Intensity: Check the output regularly with a radiometer, as even small drops in intensity can lead to under-cured parts.

- Prevent Shadowing: Ensure the light path is completely clear, as any area blocked by a component will remain liquid.

- Manage Dwell Time: Use the system’s digital timer to ensure every part receives an identical exposure duration for consistent quality.

What Safety Considerations Are Important With UV LED Spot Curing?

Safety considerations with UV LED spot curing include safeguarding eyes and skin from direct UV exposure and using proper protective gear. Because these systems are highly focused, the intensity at the point of cure is extremely high, and even reflected light from metallic surfaces can be hazardous.

You must ensure that operators wear UV-rated safety glasses and opaque gloves to prevent skin burns and long-term ocular damage. Using localized shielding, such as UV-absorbing curtains or opaque enclosures around the curing station, is a best practice that protects nearby personnel from stray radiation while the system is active.

What Are the Key Takeaways on UV LED Spot Curing Systems?

UV LED spot curing systems deliver controlled, focused UV energy to cure adhesives and coatings with precision. Success in high-stakes assembly relies on the correct alignment of light output, material chemistry, and operator safety protocols.

- Precision Targeting: Ideal for small areas, intricate bonds, and heat-sensitive components.

- Wavelength Matching: Critical to match the LED peak with the adhesive's specific photoinitiator needs.

- Process Stability: Use calibrated radiometers and digital timers to ensure consistent energy delivery.

- Safety First: Protect operators with appropriate UV-rated PPE and localized station shielding.

What Types of UV LED Spot Curing Systems Are Available?

What types of UV LED spot curing systems exist? You will typically choose between single-channel units for simple tasks and multi-channel controllers that can drive several light guides for complex, multi-point assembly. You can explore a detailed UV LED spot curing system guide to see which form factor fits your workbench or automated cell.

How Do Handheld UV LED Curing Lamps Compare to Spot Systems?

How do handheld UV LED curing lamps differ from fixed spot curing systems? While spot systems are usually stationary or integrated, a handheld UV LED curing lamp provides maximum mobility for repairs or large structures. They are less precise than a wand-based spot system but offer greater flexibility for non-standard geometries.

When Are Battery UV LED Curing Lights Useful?

When are battery-operated UV LED curing lights useful? Choosing battery UV LED curing lights or a battery-operated UV LED curing light is best for field work where power cables cannot reach. These cordless tools are ideal for inspecting or repairing large parts where a tethered system would be a safety hazard.

How Do UV Adhesive Wavelength Needs Affect Spot Curing?

How do adhesive wavelength requirements affect spot curing choices? Because of the narrow spectral output of LEDs, selecting the correct UV adhesive curing wavelengths is the most critical technical decision. If the wavelength is slightly off, the bond may fail under mechanical stress despite looking cured.

How Does Cure Time Vary With Intensity and Exposure?

How does UV intensity and exposure duration affect cure time with a spot system? Understanding UV adhesive curing time helps you balance conveyor speed or manual dwell time. This ensures every part receives the proper energy dose ($J/cm^2$) needed for a complete chemical cross-linking.

What Is Tacky Cure and How Can Spot Tools Help?

What is tacky cure and how does targeted UV LED spot curing help resolve it? Surface tackiness occurs when oxygen inhibits the top layer; a specialized UV LED spot curing tacky cure approach can often overcome this layer using high intensity to produce a hard, dry finish.

What Safety Gear Should Operators Use With UV LED Spot Curing?

What safety gear should operators use when working with UV LED spot curing systems? Using correct UV LED curing safety gear, such as specialized eyewear and skin protection, is mandatory. High-intensity spot systems pose a significant risk of accidental exposure if not handled with proper PPE.

Final Thoughts on Spot Curing Systems

Finalizing your spot curing process requires a holistic view of how light, chemistry, and handling interact on the shop floor. While the hardware provides the intense energy needed for rapid production, your discipline in maintaining working distances and verifying wavelengths ensures that every part meets your quality standards. By treating the spot curing system as a precision instrument rather than a simple light source, you eliminate the variables that lead to bond failures. This data-driven approach allows you to scale your production with confidence, knowing that your curing process is both safe and remarkably consistent.