UV LED Spot Curing Systems: Features That Matter Most

Selecting the right ultraviolet equipment requires you to look beyond simple power ratings and focus on the technical attributes that drive process stability. A UV LED spot curing system is a precision instrument designed to deliver high-energy light to restricted bond areas without damaging sensitive surroundings.

This guide explains the hardware specifications that dictate your manufacturing throughput and bond reliability. By prioritizing features like spectral matching and thermal management, you can ensure your production line remains predictable while meeting the rigorous quality demands of modern assembly.

What Makes a UV LED Spot Curing System Valuable

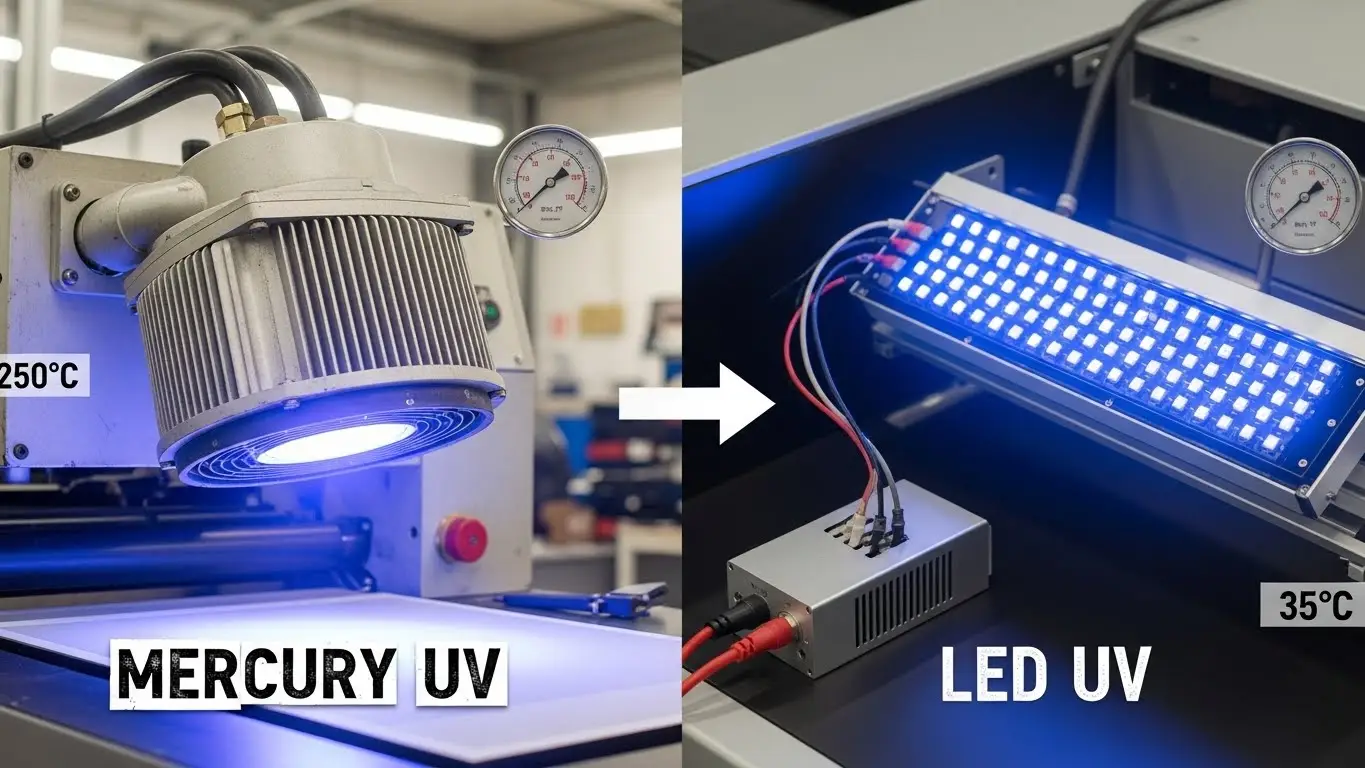

A UV LED spot curing system’s value comes from its ability to deliver controlled, focused UV energy for precise curing of adhesives and coatings. You can target a specific 3 mm bond line on a complex circuit board without exposing nearby plastic components to radiant heat. This localized approach prevents substrate warping and reduces energy waste compared to wide-area flood lamps. The concentrated beam ensures that the photoinitiators receive the energy density required to reach full mechanical strength in seconds, making these systems essential for high-precision work.

Why Wavelength Flexibility Matters

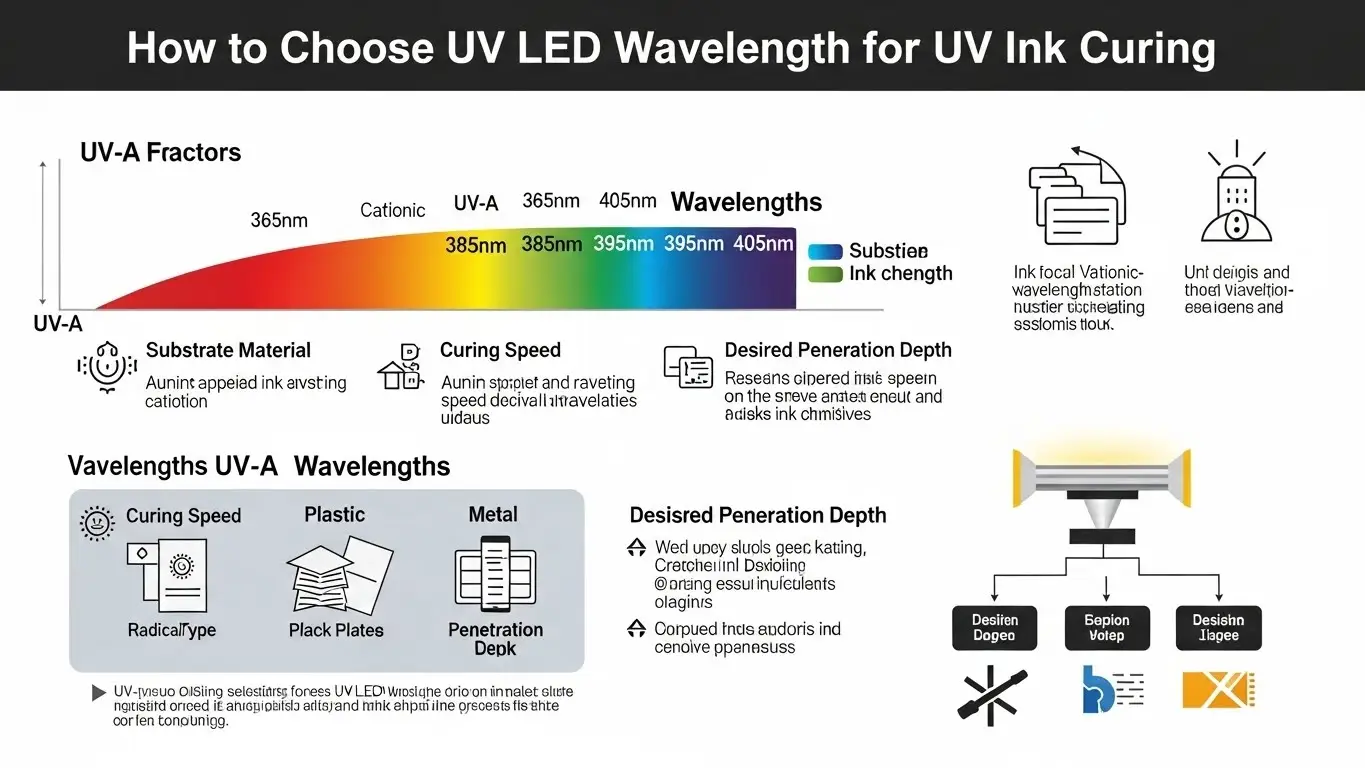

Wavelength flexibility matters because different adhesives and photoinitiators absorb UV light at specific wavelengths, and matching those increases cure effectiveness. You should verify if your resin reacts best to 365 nm, 385 nm, or 395 nm, as using a mismatched source can lead to incomplete polymerization. Many modern systems allow you to swap LED heads or use multi-wavelength controllers to accommodate varied adhesive chemistries. This adaptability ensures you can use the same base system for different products, provided the spectral peak matches the requirements of your material's technical data sheet.

How Intensity and Power Density Affect Curing

Intensity and power density affect curing because stronger output delivers the required UV dose faster and more thoroughly. You can view irradiance ($W/cm^2$) as the strength of the photons; high intensity is required to penetrate thick resin layers or deeply pigmented materials. When your system produces high power density, you can reduce exposure times, which increases your hourly throughput. Higher intensity also helps you overcome oxygen inhibition at the surface of the adhesive, preventing the sticky or gummy finish that often occurs with lower-powered curing setups.

What Spot Size and Beam Uniformity Mean for Results

Spot size and beam uniformity matter because they determine how evenly UV energy covers the work area, influencing cure consistency. You need a beam that delivers the same intensity at the edges as it does in the center to avoid soft spots in your bond. If the beam is not uniform, the center of your adhesive might be brittle while the perimeter remains under-cured. Selecting the correct spot size for your specific part geometry ensures that all the light you pay for is applied to the bond line, rather than being wasted on the surrounding substrate.

Why Ergonomics and User Control Influence Performance

Ergonomics and user control features matter because comfortable handling, adjustable settings, and intuitive controls help operators apply curing more consistently. You should look for systems with programmable timers and adjustable power levels to eliminate the guesswork of manual counting. Digital displays that show real-time intensity help you maintain a stable process window across different shifts. Ergonomic wand designs and foot-pedal activation reduce operator fatigue, which is a common cause of positioning errors and inconsistent bond quality during long production runs.

What Maintenance and Reliability Features Lower Downtime

Maintenance and reliability features matter because regular upkeep, clean optics, and stable output help systems stay productive over time. You should prioritize systems with easily replaceable protective windows or modular LED heads that can be swapped without a complete teardown. Built-in diagnostics that monitor the internal temperature of the LED array help you prevent premature diode failure. A system that is easy to clean and monitor ensures that your light output remains within calibration, protecting your equipment and preventing the shipment of under-cured products to your customers.

What Are the Key Takeaways on UV LED Spot Curing System Features

The most impactful features of UV LED spot curing systems include wavelength match, intensity, beam quality, user control, and maintainability. Selecting a system that offers the right balance of these attributes is your best path toward a repeatable and high-quality bond.

- Wavelength Matching: Match the LED peak to your adhesive's photoinitiators.

- Irradiance Strength: Use high intensity to drive faster cure speeds and deeper penetration.

- Beam Profile: Ensure your beam is uniform to prevent localized under-curing.

- Calibration Tools: Use digital controls and radiometers to verify your energy delivery.

What UV LED Spot Curing Systems Are Available?

What kinds of UV LED spot curing systems exist and what are their typical form factors? You can find a UV LED spot curing system in various setups, from single-wand units for benchtop repairs to multi-channel spot curing systems integrated into automated assembly lines.

How Do Handheld UV LED Curing Lamps Fit Into Spot Curing Workflows?

How do handheld UV LED curing lamps operate and how do their features compare? A handheld UV LED curing lamp provides portability for field work, but you must follow proper handheld lamp usage protocols to match the precision of a fixed spot curing station.

How Does Wavelength Choice Affect Adhesive Curing?

How does selecting the correct UV LED wavelength influence the curing outcome? Choosing the right UV adhesive curing wavelengths is your most important technical decision, as an incorrect spectral match prevents the molecular cross-linking required for structural strength.

How Does Cure Time Relate to System Features?

How do intensity and wavelength choices influence how long curing takes? Understanding UV adhesive curing time helps you calibrate your production speed, as higher intensity and a perfect wavelength match allow you to achieve a full cure in fewer seconds.

When Are Battery-Operated UV LED Curing Lights Useful?

When are battery-operated UV LED curing lights useful and how do their features compare? Using battery UV LED curing lights or a battery-operated UV LED curing light is ideal for on-site repairs where power cables are restricted, though you must monitor battery levels to prevent intensity drops.

What Is Tacky Cure and How Do System Features Help Prevent It?

What is tacky cure and how do intensity and beam quality help avoid it? A UV LED spot curing tacky cure usually happens when the surface receives insufficient energy to overcome oxygen inhibition; high intensity and a uniform beam are the primary solutions.

Final Thoughts

Finalizing your equipment choice means finding a system that matches your specific adhesive chemistry and your operator's workflow. While it is tempting to focus only on the initial purchase price, the features that drive reliability—like thermal monitoring and optics accessibility—will determine your long-term operational costs. By ensuring your system provides a uniform beam and a perfect wavelength match, you remove the hidden variables that lead to bond failure. This focus on technical specifications ensures your curing station is a stable and profitable part of your manufacturing facility.