How to Avoid a Tacky Cure with UV LED Spot Curing

A tacky cure happens when a UV-curable adhesive hardens at the surface but remains partially uncured or sticky underneath. You can identify this issue when the top layer of your resin feels dry, yet the bond fails under slight mechanical stress because the base layer stays liquid.

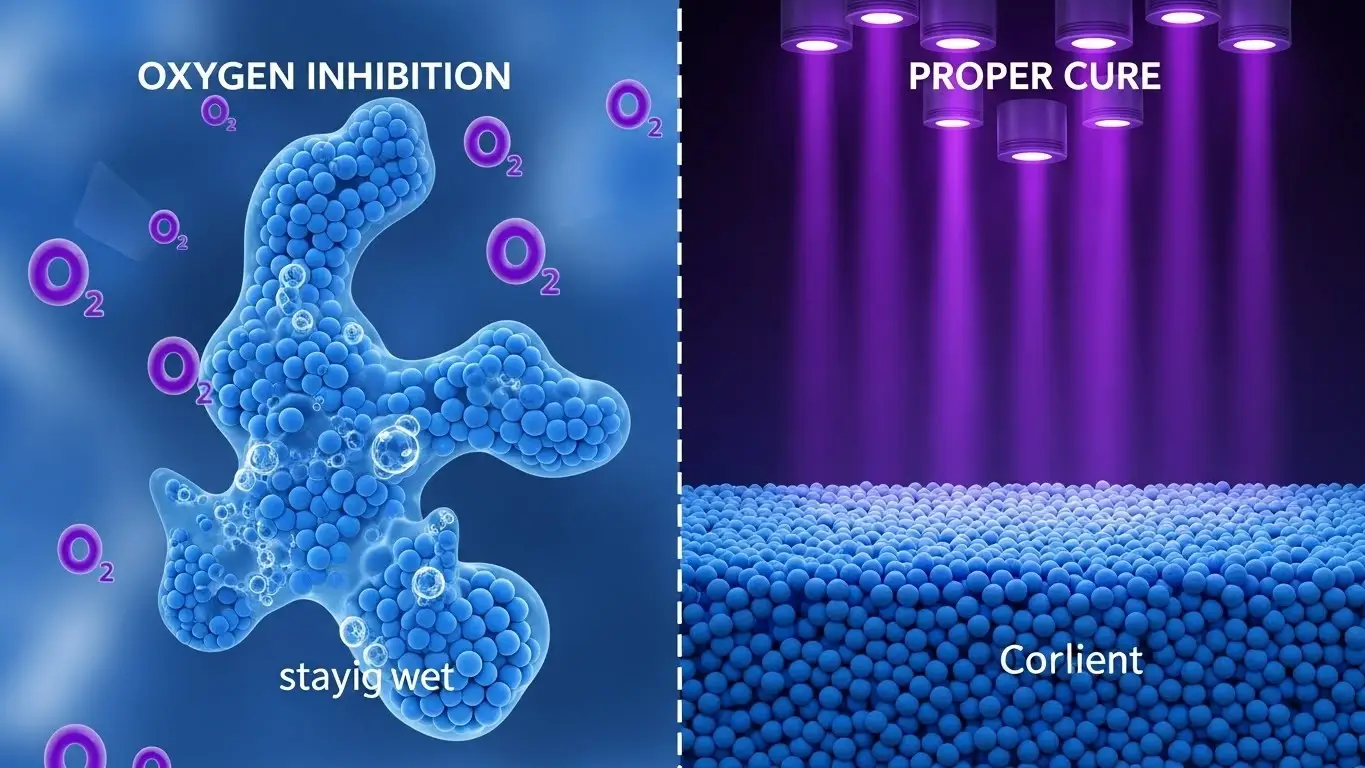

This problem often stems from oxygen inhibition at the surface or a failure of the ultraviolet photons to penetrate the full depth of the bond. To ensure your assemblies meet industrial standards, you must adjust your curing parameters to reach the bottom of the adhesive layer.

What Is a Tacky Cure in UV LED Spot Curing?

A tacky cure happens when a UV-curable adhesive hardens at the surface but remains partially uncured or sticky underneath. You will often see this when oxygen in the air reacts with the top layer of the adhesive, preventing the photoinitiators from completing the polymerization process. This results in a surface that stays slightly "wet" or gummy to the touch, which can attract dust and compromise the final aesthetic of your part. If you do not resolve this, your bond strength remains lower than specified, as the internal structure of the adhesive has not reached its intended cross-linked density.

Why Does Tacky Cure Happen With Spot Curing?

Tacky cure occurs because the UV energy delivered was not enough in intensity or duration to fully initiate polymerization throughout the adhesive. You might experience this if you use a lamp that does not produce enough irradiance to overcome the chemical resistance of the resin. When the light is too weak, the photons are absorbed by the top few microns of the material, leaving nothing for the deeper sections. Poor positioning of the spot wand or holding the light at an extreme angle can also create "shadowed" areas where the adhesive receives almost no energy, resulting in liquid pockets.

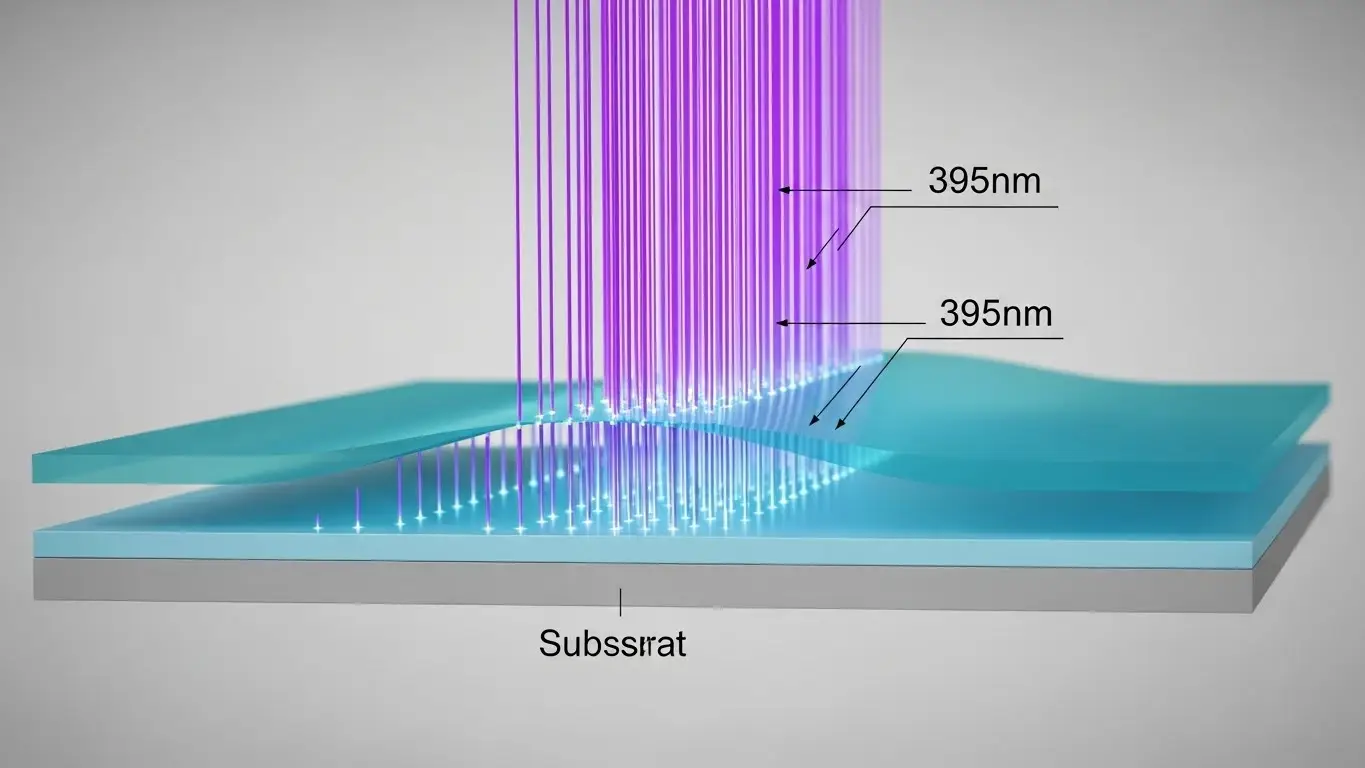

How Does Wavelength Affect the Risk of Tacky Cure?

Wavelength affects tacky cure because photoinitiators in adhesives respond strongly to specific UV wavelengths and mismatches reduce cure efficiency. You must ensure that the peak output of your LED lamp matches the absorption profile of your adhesive, typically at 365nm, 385nm, or 395nm. If you use a 405nm lamp on an adhesive designed for 365nm, the chemical reaction will be sluggish. This spectral mismatch often leads to a surface-only cure where the top looks dry but the lack of energy absorption prevents the base from hardening correctly.

How Do Exposure Time and Intensity Influence Tacky Cure?

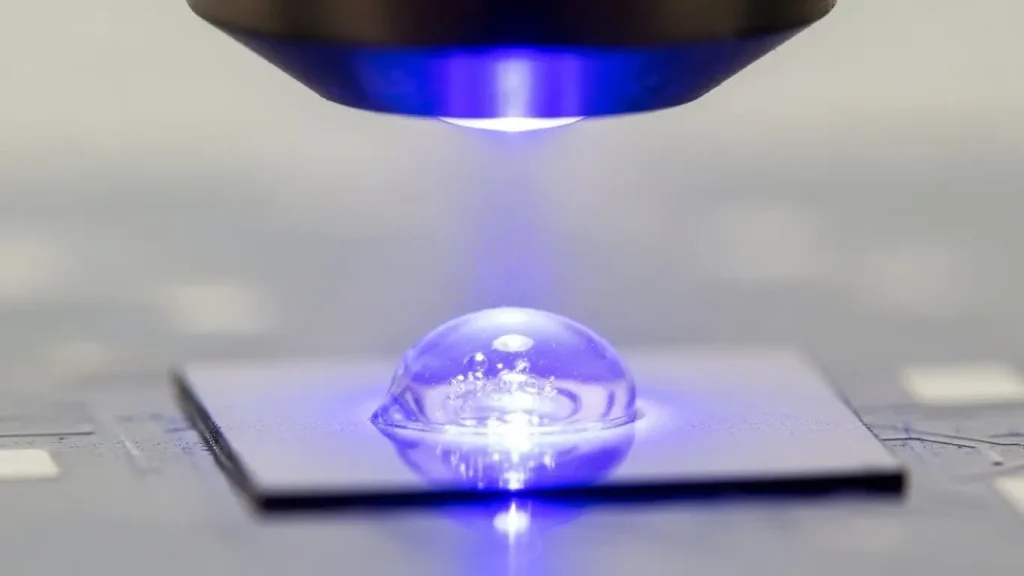

Both exposure time and UV intensity influence tacky cure risk because adequate dose must reach the adhesive to convert it fully from liquid to solid. You can think of intensity as the "power" behind the photons and time as the "volume" of energy delivered. If your intensity is too low, the photons cannot push through the surface layer to cure the base. Conversely, even with high intensity, if your exposure duration is too short, the chemical chain reaction will stall before completion. Finding the right balance ensures that every part of the bond receives the required Joules per square centimeter.

What Practical Techniques Reduce Tacky Cure in Spot Curing?

Preventing a tacky cure requires consistent positioning, correct distance, matched wavelength, and thoughtful exposure planning. You can improve your results by following these steps:

- Standardize Your Distance: Use a spacer to keep the lamp head at the same height for every part to maintain stable intensity.

- Boost Intensity: Increase the power setting on your controller to help photons overcome oxygen inhibition at the surface.

- Extend Dwell Time: Use a programmed timer instead of manual activation to ensure the adhesive receives a full energy dose.

- Maintain Your Optics: Clean the tip of your light guide daily to ensure no adhesive residue is blocking the UV beam.

- Verify with Test Strips: Use UV-sensitive labels to confirm that the energy is reaching the bottom of your bond line.

What Are the Key Takeaways for Avoiding Tacky Cure With UV LED Spot Curing?

Avoiding tacky cure with UV LED spot curing depends on matching the right wavelength, delivering sufficient UV dose, and applying consistent technique. You get the most reliable bonds when you treat the curing process as a data-driven manufacturing step.

- Match your LED wavelength exactly to the adhesive's photoinitiators.

- Keep the lamp close to the surface to maximize energy delivery.

- Use programmed timers to eliminate variations in exposure duration.

- Monitor your equipment's output with a radiometer to catch intensity drops.

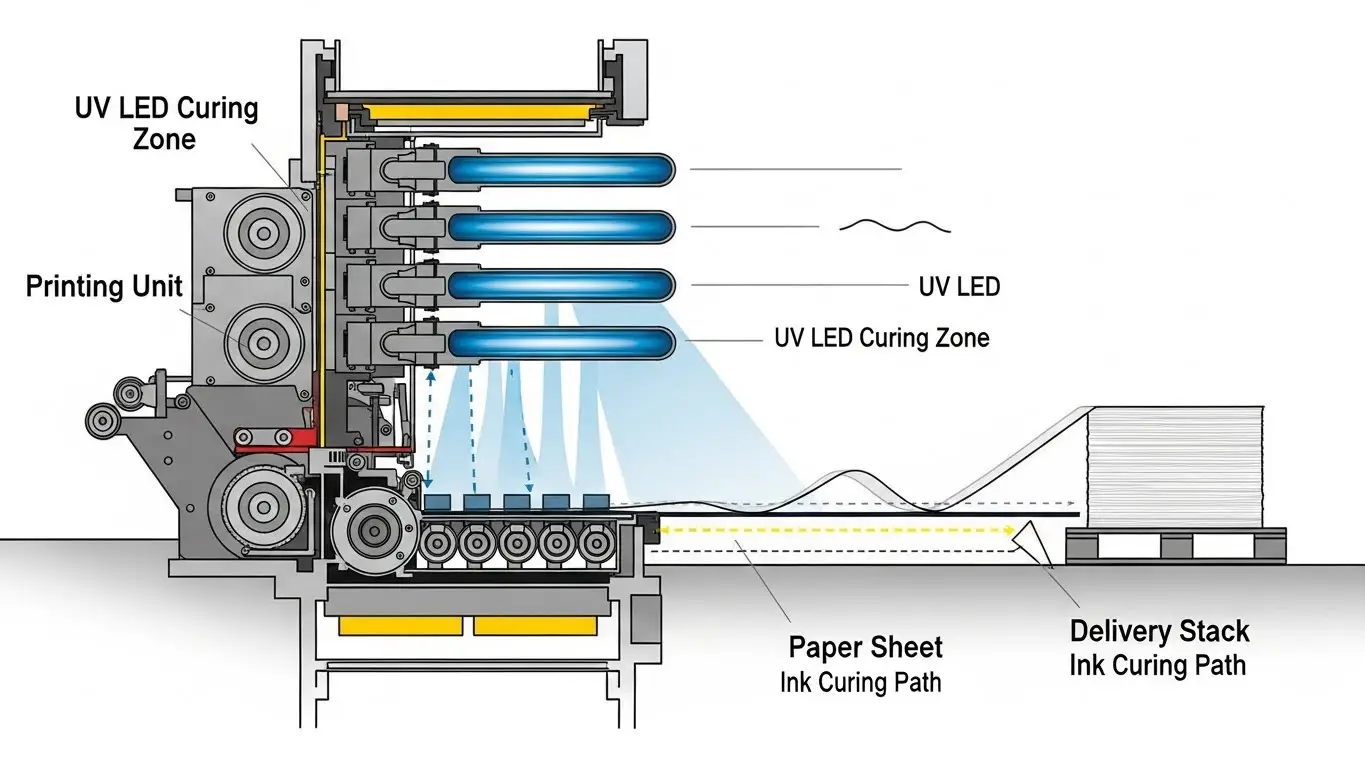

What Types of UV LED Spot Curing Systems Are There?

What kinds of UV LED spot curing systems exist and what are their form factors? You can choose between single-channel units for simple tasks or multi-channel controllers that drive several light guides for complex assembly. For more details on equipment types, see our guide on the UV LED spot curing system or explore various spot curing options.

How Do Handheld UV LED Curing Lamps Work and Affect Cure Quality?

How do handheld UV LED curing lamps operate and how does handling influence tacky cure risk? These tools provide portability but require you to maintain a steady hand; improper handheld lamp usage can cause intensity variations. Learn more about how a handheld UV LED curing lamp functions to prevent surface defects.

How Do Wavelength Choices Influence Adhesive Cure?

How does selecting the correct UV wavelength influence adhesive curing and reduce surface-only cure? Because LEDs have narrow spectral bands, choosing the right UV adhesive curing wavelengths is the most important step in ensuring a deep, thorough cure without leaving the surface tacky.

How Does Cure Time Relate to Tacky Cure?

How does adjusting exposure duration and intensity impact whether tacky cure develops? Understanding the UV adhesive curing time requirements for your specific chemistry helps you set the correct dwell time, ensuring the energy dose reaches the base of the bond.

When Are Battery-Operated UV LED Curing Lights Helpful and What Does That Mean for Tacky Cure?

When are battery-operated UV LED curing lights helpful and how does their intensity affect tacky cure? These cordless tools are excellent for field work, but you must monitor the charge of a battery-operated UV LED curing light or other battery UV curing lights to ensure intensity doesn't drop and cause a sticky finish.

What Safety Gear Should Operators Use With UV LED Spot Curing?

What safety gear should you use when working with UV LED spot curing systems? High-intensity beams can cause accidental exposure, so wearing proper UV LED curing safety gear like UV-rated eyewear and gloves is mandatory to protect your eyes and skin while you solve curing issues.

Final Thoughts

Solving the problem of a tacky cure turns your manual assembly into a high-precision process. While the chemistry of oxygen inhibition is complex, your solution remains simple: provide enough intensity and the correct wavelength to force the reaction to completion. By standardizing your distance and using timed exposures, you remove the human variables that lead to sticky bonds. A hard, dry finish is the ultimate proof that your curing system is operating within its ideal technical window.