The Comprehensive Guide to High-Power UV LED Curing Systems: Engineering, Application, and Strategic Selection

In the landscape of modern industrial manufacturing, the transition from traditional mercury vapor lamps to ultraviolet (UV) light-emitting diode (LED) technology represents one of the most significant shifts in process engineering. While low-power UV LEDs have dominated the consumer and small-scale assembly markets for years, the advent of high-power UV LED curing systems has opened the door to high-speed, high-volume production lines that were previously the sole domain of gas-discharge lamps.

This comprehensive guide examines the technical specifications, operational nuances, and real-world applications of high-output UV LED systems. By understanding the intersection of optical physics, thermal management, and polymer chemistry, you can optimize your production line for maximum throughput and structural bond integrity.

What Defines a High-Power UV LED Curing System?

A high-power UV LED curing system is characterized by elevated UV output and the capability to deliver high intensity over large areas or at high throughput. Unlike the low-power "spot" or "handheld" units used for intermittent manual assembly, high-power systems are engineered for continuous industrial operation.

Irradiance Thresholds

In technical terms, a system is generally classified as "high power" when its peak irradiance exceeds 12 to 16 $W/cm^2$ at the lamp window. Some state-of-the-art arrays now push into the range of 25 to 30 $W/cm^2$. This level of energy is required to initiate near-instantaneous polymerization in fast-moving web printing, fiber optic drawing, and high-speed coating lines.

Array Density

The "power" of these systems is a result of diode density. High-power heads utilize "Chip-on-Board" (COB) technology, where hundreds or even thousands of LED chips are packed into a tight configuration. This density minimizes the "dips" in intensity between individual diodes, providing a nearly uniform energy field across the entire curing width.

Continuous Duty Cycles

Unlike standard units that may require cooling periods, high-power industrial systems are designed for 100% duty cycles. They must operate 24 hours a day, 7 days a week, without experiencing a drop in UV intensity—a feat that requires sophisticated electronics and thermal management.

Core Specifications: Beyond the Marketing Numbers

When you evaluate a high-power UV LED curing system, looking at the "peak wattage" is insufficient. You must analyze several interconnected specifications to determine if a system will actually cure your material at your required line speed.

Irradiance ($W/cm^2$) vs. Energy Density ($J/cm^2$)

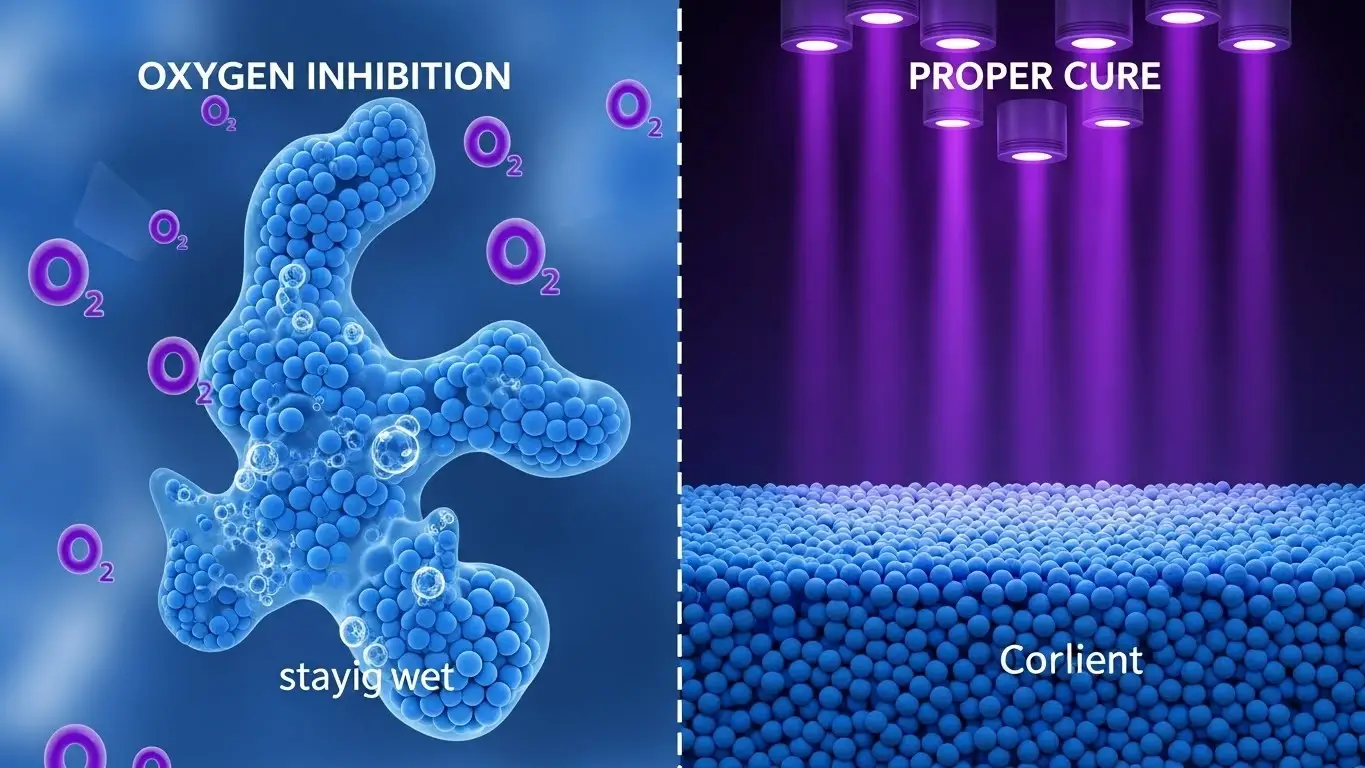

- Irradiance: This is the "instantaneous" power of the light hitting the surface. It is critical for overcoming oxygen inhibition, which can cause surface tackiness.

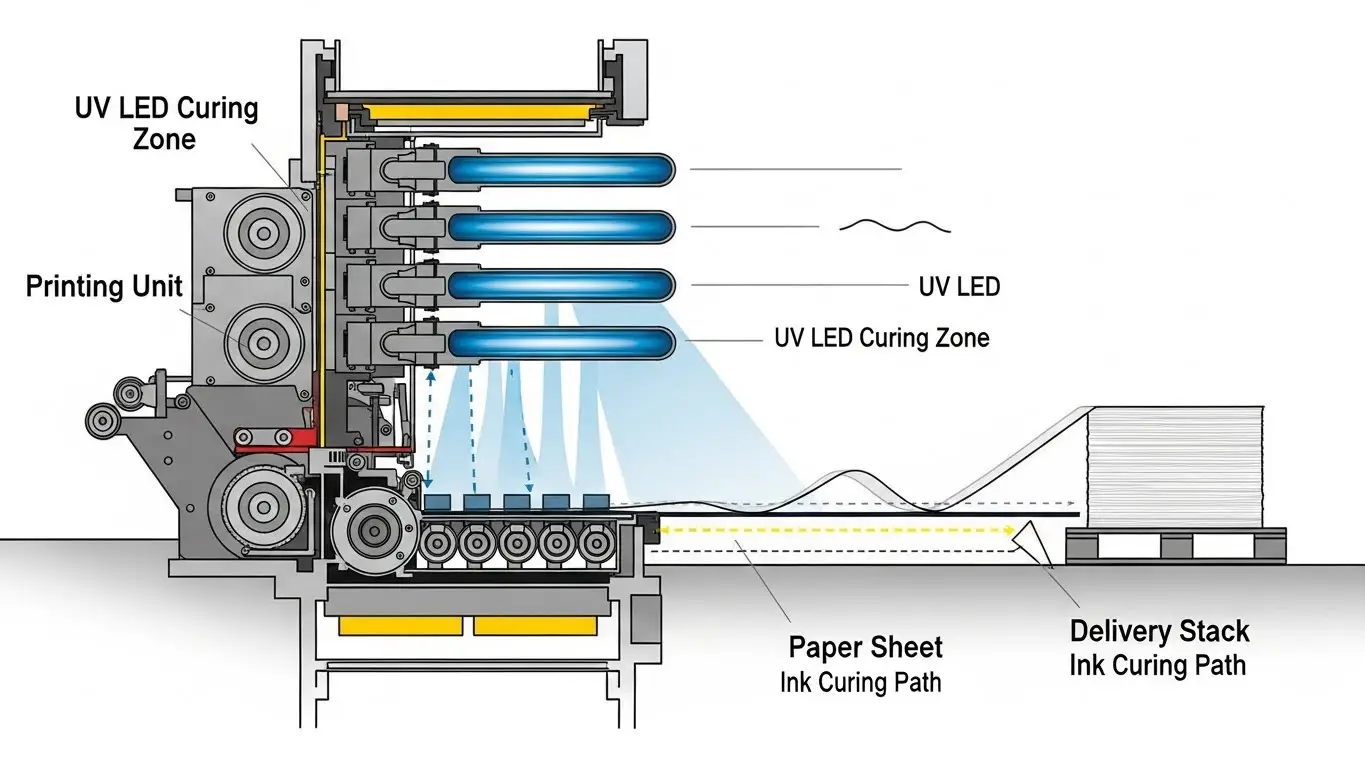

- Energy Density (Dose): This is the total amount of energy delivered over time. If your conveyor moves at 100 meters per minute, the time the part spends under the light is tiny. The system must have enough "raw power" to deliver the required dose within that split second.

Spectral Peak and FWHM

UV LEDs emit a very narrow band of light. A "365 nm" lamp actually emits a bell curve of light centered at 365 nm.

- Peak Wavelength: Must match your adhesive’s photoinitiator.

- Full Width at Half Maximum (FWHM): Usually around 10–15 nm. This narrowness is why LED systems are more energy-efficient than mercury lamps, which waste energy on wavelengths your adhesive doesn't need.

Uniformity and "Stitchability"

For wide-format applications, multiple LED heads are often "stitched" together. A high-quality system maintains a +/- 5% uniformity across the entire length. If there is a "cold spot" where the heads meet, you will see a visible line of uncured material on your product.

The Thermal Challenge: Why Cooling Is a Specification

In high-power UV LED systems, only about 30% to 40% of the electrical energy is converted into UV light; the remaining 60% to 70% is converted into heat. If this heat is not removed from the LED junction, the light output will drop, the wavelength will shift, and the diodes will eventually burn out.

Air-Cooled Systems: Limits and Use Cases

Air-cooled systems use high-speed fans and aluminum heat sinks.

- Advantages: Lower initial cost, easier integration, no plumbing required.

- Limitations: Generally capped at around 12–14 $W/cm^2$. They are also sensitive to ambient factory temperatures; if your facility gets hot in the summer, the lamp’s output may drift.

Water-Cooled Systems: The Industrial Gold Standard

For intensities above 16 $W/cm^2$, water cooling is mandatory.

- How it works: A chiller circulates a coolant (usually distilled water or a glycol mix) through micro-channels directly behind the LED COB.

- Stability: Water cooling allows the LEDs to run at a much lower, more consistent junction temperature. This stability ensures that the UV output remains identical from the first minute of the shift to the last.

Wavelength Selection: The Spectral Key to Success

The choice of wavelength is perhaps the most critical technical decision in process design. In high-power applications, the wrong wavelength won't just slow down production—it will prevent a structural cure.

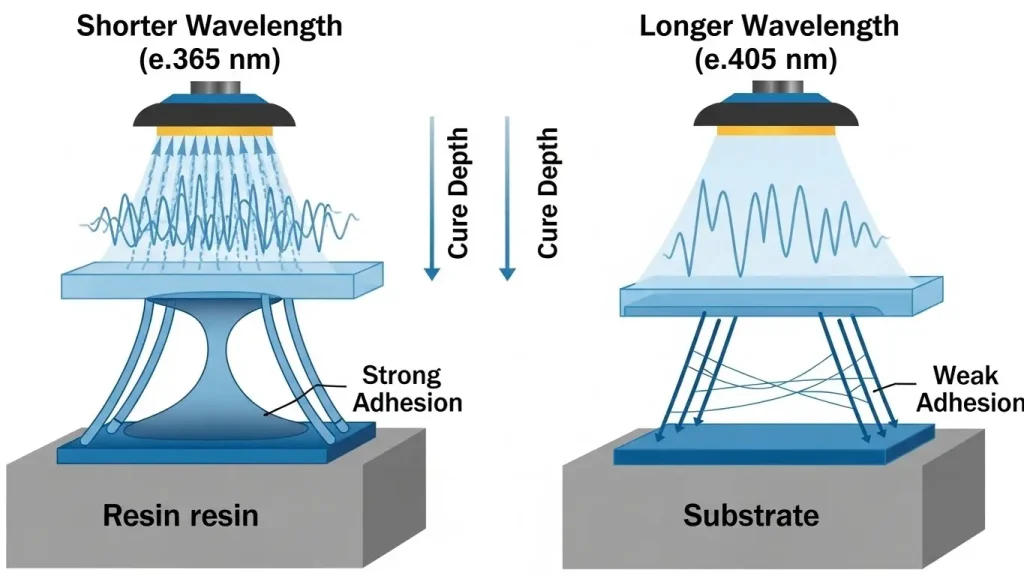

365 nm: The Surface Specialist

365 nm photons have high energy but lower penetration. They are the best choice for:

- Clear coatings and thin-film adhesives.

- Applications where you need a hard, scratch-resistant surface.

- Overcoming oxygen inhibition (the "tacky" layer).

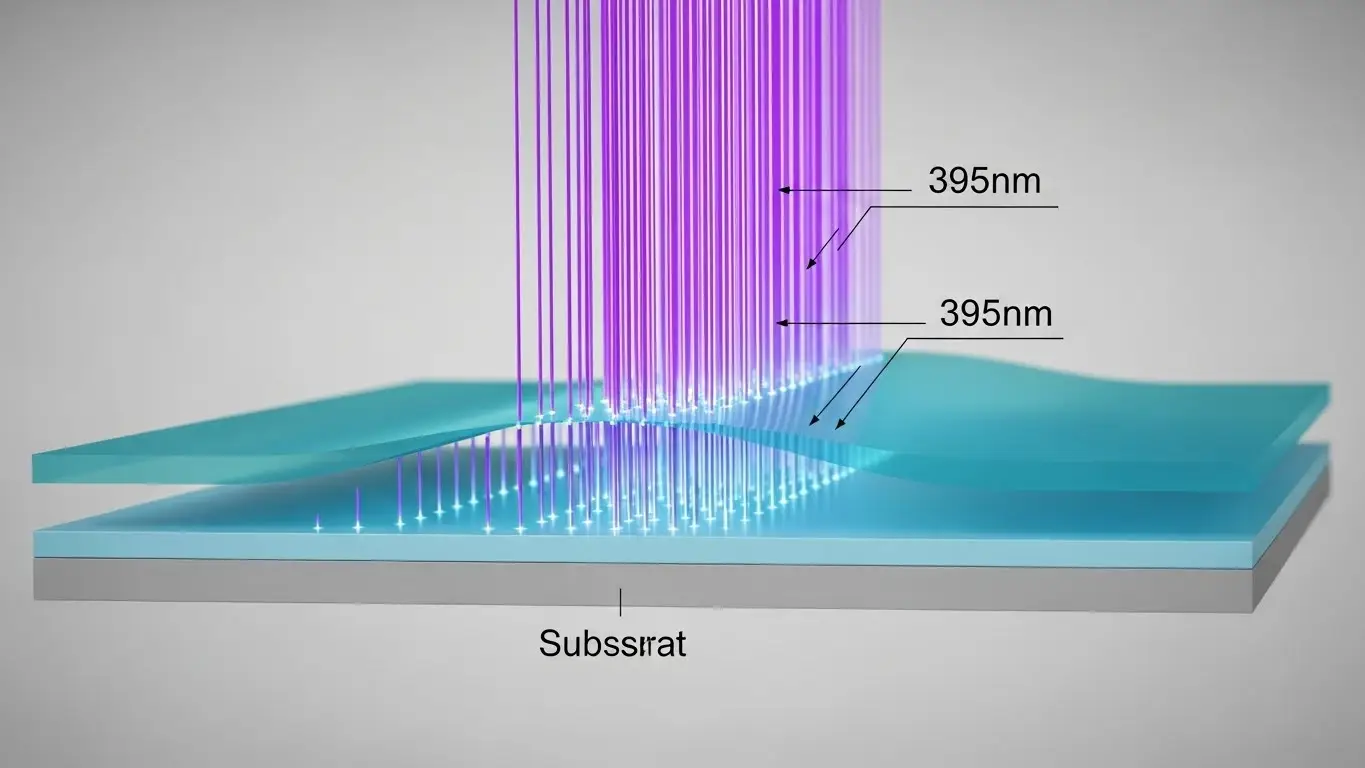

385 nm and 395 nm: The Penetration Experts

These longer wavelengths travel deeper into materials. They are used for:

- Pigmented Inks: Shorter UV is often absorbed by pigments before it reaches the bottom of the ink layer. 395 nm can "see" through the pigment.

- Thick Potting/Gap Filling: If you are curing a 5 mm thick resin, 365 nm will likely stop halfway. 395 nm or 405 nm will reach the substrate.

- Substrate Bonding: If you are curing through a plastic part, you must ensure the plastic doesn't block the UV. Many "UV-stabilized" plastics block 365 nm but allow 395 nm to pass.

Real-World Applications of High-Power Systems

Where do these "monsters" of the UV world actually live? They are found in environments where speed and reliability are non-negotiable.

High-Speed Flexographic and Digital Printing

Modern label presses run at hundreds of feet per minute. To cure the ink in the fraction of a second the substrate passes under the lamp, high-power water-cooled arrays are used. These systems allow for "low-migration" printing, essential for food packaging.

Fiber Optic and Wire Coating

In fiber optic drawing, the glass strand moves at extreme speeds. The UV-curable buffer coating must be fully cured instantly to prevent the fiber from sticking to itself on the take-up reel. Only high-power LED systems can provide the concentrated "annular" (circular) intensity required.

Automotive Headlamp and Sensor Assembly

Automotive components must survive extreme heat and vibration. High-power systems ensure that the structural adhesives used to bond headlamp lenses or sensor housings achieve a full "through-cure," preventing delamination during the vehicle's 15-year lifespan.

How to Calculate the Required Dose ($J/cm^2$)

To ensure a consistent process, you must move from "feeling" the cure to measuring it. The formula is simple, but the variables are many:

$$Dose (J/cm^2) = \frac{Irradiance (W/cm^2) \times Exposure Time (seconds)}{Substrate Speed}$$

In a high-power environment, your exposure time is often less than 0.1 seconds. If your adhesive requires 2.0 $J/cm^2$ to reach full strength, and your line speed is fixed, you must increase the irradiance. This is why "high power" is not a luxury—it is a mathematical necessity for high-speed production.

Strategic Maintenance: Protecting Your Investment

A high-power UV LED system is a precision instrument, not a simple lightbulb. If you neglect maintenance, your "20 $W/cm^2$" system can quickly become a "12 $W/cm^2$" system, leading to uncured products.

Optical Window Maintenance

The quartz window protecting the LEDs must be cleaned daily. In high-power systems, any dust, ink mist, or adhesive vapor on the window will absorb UV energy. Because of the high power density, this absorbed energy turns into heat, which can literally bake the contaminant onto the window or cause the quartz to crack.

Chiller Health

In water-cooled systems, the coolant must be checked for conductivity and microbial growth. Scale buildup inside the LED head is catastrophic; it acts as an insulator, preventing the water from removing heat. A "thermal alarm" on a high-power system is an emergency that must be addressed immediately to prevent diode degradation.

Radiometric Mapping

You should map the output of your system weekly using a high-speed radiometer. This allows you to catch "dead zones" or gradual intensity decay before they result in failed bonds. In high-power systems, a 10% drop in intensity is enough to move your process outside the validated quality window.

Safety in the High-Power Zone

The sheer volume of photons emitted by these systems makes safety a primary engineering concern. We are no longer talking about simple "eye irritation."

- Specular Reflection: At 20 $W/cm^2$, even light reflecting off a shiny aluminum part can cause a permanent retina burn in milliseconds.

- Ozone-Free Benefits: Unlike mercury lamps, LEDs do not produce ozone. This eliminates the need for expensive ducting and exhaust systems, making the workplace much safer for operators.

- Shielding: High-power systems should always be enclosed in a UV-opaque light box with safety interlocks that kill the power if a door is opened.

Key Takeaways for Process Engineers

When you are tasked with specifying a high-power UV LED curing system, keep these four principles in mind:

- Intensity Triggers the Cure: High irradiance is what overcomes oxygen inhibition and gives you a tack-free surface.

- Dose Completes the Cure: You must have enough total energy to reach the required cross-link density at your maximum line speed.

- Cooling Dictates Stability: For high-output applications, water cooling provides the thermal baseline needed for 24/7 consistency.

- Wavelength is the Lock: You must match the spectral peak of the lamp to the chemical absorption of the adhesive.

What System Specifications Should You Look at in UV LED Curing Systems?

Evaluating a system requires looking at the irradiance at your specific working distance, the spectral FWHM, and the uniformity across the entire array. You can learn more about interpreting UV LED curing system specs to ensure your equipment matches your process needs.

How Does Water Cooling Work in High-Power Systems?

For systems exceeding 16 $W/cm^2$, liquid thermal management is essential. Read about the mechanics of UV LED water cooling to understand how chillers and micro-channels preserve diode life.

How Do Air-Cooled and Water-Cooled Systems Compare for High-Power Use?

Choosing between the two depends on your intensity "ceiling" and the ambient environment of your factory. Review our side-by-side comparison of cooling methods for more technical context.

How Does Intensity Affect Curing in High-Power Applications?

Higher intensity leads directly to faster cure speeds and deeper through-cure in pigmented resins. Review how UV LED intensity levels affect the final physical properties of your materials.

How Is UV LED Dose Calculated in High-Power Settings?

At high conveyor speeds, the relationship between time and power is critical. Use our guide to calculate UV LED dose to maintain your quality standards.

How Does Uniformity Affect Curing Quality in High-Power Systems?

Even energy distribution across the curing width prevents "soft spots" and bond failure. Learn why UV LED curing uniformity is a key performance indicator for high-throughput lines.

How Does Lamp Temperature Influence High-Power Operation?

Heat is the enemy of stable UV output. Explore the relationship between lamp temperature and performance to see why thermal management is the foundation of consistency.

What Maintenance Practices Support Consistent Performance in High-Power Systems?

Proactive care is the only way to protect a high-value LED investment. Follow our UV LED curing system maintenance checklist for industrial-grade uptime and reliability.

Final Thoughts

The adoption of high-power UV LED curing systems is more than a simple equipment upgrade; it is an investment in process control. While the initial capital expenditure for a water-cooled, high-intensity system is higher than for traditional lamps, the long-term benefits are undeniable. You get 20,000+ hours of lamp life, zero mercury disposal costs, and a significantly lower carbon footprint.

The best system for your line is the one that provides exactly enough irradiance to overcome the chemical inhibitors of your resin while maintaining a stable thermal baseline. By focusing on the data—irradiance, dose, and wavelength—you remove the guesswork and ensure that your production line is as efficient as the chemistry it employs.