What is UV Tape Curing?

- UV tape curing can be described as a process involving curing via an ultraviolet (UV) lamp of an adhesive tape. The difference lies in the fact that, unlike the conventional process of heat curing, where the curing mechanism occurs by heating that adhesive, in this instance, the presence of the photo initiators in this adhesive is activated by using the UV LED technology. The result? Immediate adhesion, superior adhesion, tensile strength, and resistance.

- The application of UV curing is destined to become part of the norm in industries like electronics, medical equipment, automotive, optics, and flexible packaging. The technology will ensure energy efficiency, even curing, precision, and minimize curing time.

Advanced UV curing solutions

UV Tape curing is a printing industry method of drying the ink and paper. It is carried out by the use of ultraviolet light, which is applied in drying the printed papers and other related materials. This is referred to as curing of UV Tape.

- The UV curing method is conveyed simply by placing the tapes on the plates of the surfaces that are going to be printed. The plates are then dried via the UV curing machine, such that the ink and the paper become dry.

- Also unusual, wafers may be mounted on the process utilizing wafer dicing involving fixing to wafer dicing tapes; back grinding may involve using UV-sensitive tapes. Such tapes show structural deformations immediately after being under UV light exposure, and the adhesive of these tapes becomes weaker.

- This makes and eases the procedure of picking the chips, hence eradicating the possibilities of breaking the material. The resultant effect is that UV curing, as well enables ease of handling of semiconductors, and a high yield is registered.

Great Portability of Materials

Among the primary advantages of the UV tape curing systems, one will have to specify that the systems are able to work with different substrates. Treated UV dicing tapes can treat:

- Semiconductor wafers

- Plates made of glass

- Ceramic materials

- Sensitive or heat-sensitive surfaces, others

This multi-functional aspect ensures that, in many applications, manufacturers will always be assured of one system that will save production costs and time.

Key Attributes and Technical Specs

The current UV curing systems are high-end, sophisticated systems of high efficiency and precision:

- Even UV Exposure: Gives evenness of curing over the entire tape face.

- Adjustable Wavelengths (365nm /405nm): applicable in a wide range of different tape and adhesive requirements.

- Compact design: It can be easily added to the existing semiconductor manufacturing lines.

- Energy Efficiency: By the superior performance of light sources, the quantity of power is reduced, and this is achieved without lowering the efficiency of curing.

Advantages of UV Tape Curing

- Increased and Reliable Adhesive Bonding: Enhances adhesive curing and hard-earned wafer bond.

- Increased Process Efficiency: By reducing curing times, hold times can be reduced to increase throughput.

- Cleaner Chip Release: Reduces adhesive masses as the die is divided.

- Scalability: Capable of performing small-scale studies and also large-scale semiconductor fabrication.

There are a variety of UV Tape Curing Systems.

1. Handheld UV cure machine

Little, thick, designed to be held aside for the discipline of repairs or small touch-ups.

2. The Portable UV Tape Curing Units

They targeted middle-to-large catalytic areas, e.g., automotive adhesive tapes.

3. UV Tape Curing Machines

Used in the roll-to-roll processing (packaging, assembly of electronics).

4. UV LEDs

It was manufactured to fit the optical bonding tapes, the microelectronics, and high-speed processing and curing.

Uses of UV Tape Curing

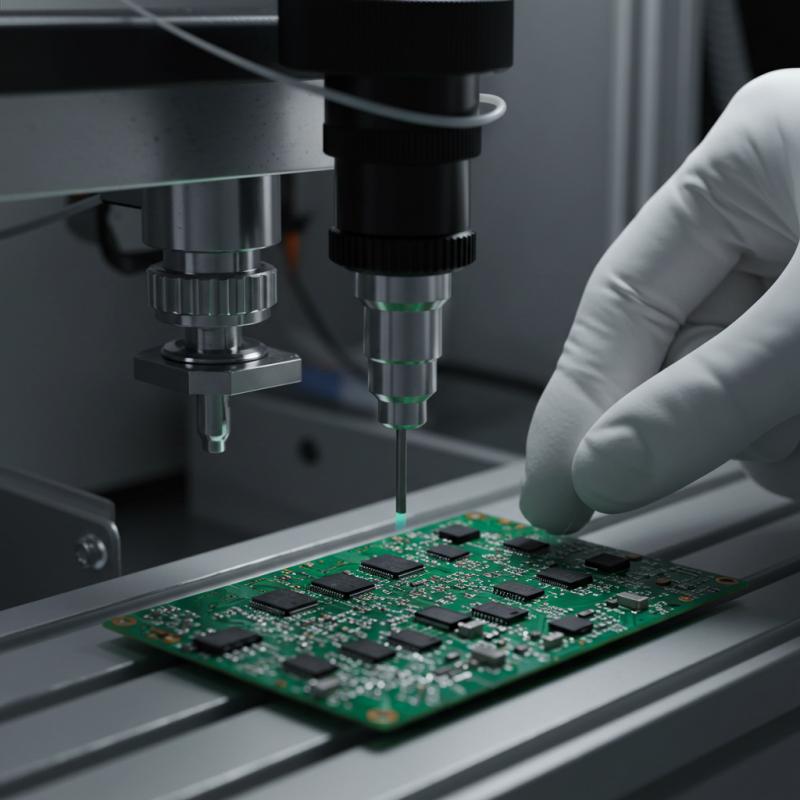

- Electronics Assembly

Accuracy and safety are a big concern for the electronics industry. UV tape curing has the potential to guarantee good clarity in both the microelectronics and the fragile printed circuit boards (PCBs) without the involvement of very high temperatures. This ensures protection of sensibilities and a solid and durable intimacy.

- Production of Medical Products

The medical industry needs tough and biocompatible adhesives. UV curable tapes are widely used in the bonding of surgical equipment, disposable medical equipment, catheters, etc. Since there is minimal heat generation during the curing process, products can be used to preserve sensitive substrates and can meet even the most demanding medical safety standards.

- Automotive Industry

UV-cure tape has been used in the automotive sector, which encompasses headlight curing, labeling, as well as finishing of surfaces. Its adhesion properties comprise rapid curing and high bonding strength, and enable the manufacturers to diminish production duration without jeopardizing the durability and quality of the products even in the most severe environmental settings.

- Optical Applications

When it is about optical devices, crystal-clear is all they need. These UV-cured optical bonding tapes, when applied, are transparent and do not cause bubbles to form as they are adhesive. This is well adapted to be applied in lenses, displays, and touch screens with a greater capability to perform better as well as to the eye.

Guidelines on Maintenance Keeping

- UV protective glasses are also essential; they should always be worn.

- All the surfaces, lenses, and panels should be cleaned regularly to yield the maximum amount of light.-

- Store devices in dry places and cooling spaces.

- The portable curing units do not need to have their lithium-ion battery overcharged.

Conclusion

UV taping of the adhesive curing is reshaping how the industries have been addressing challenges, such as bonding with an adhesive. It has also increased its popularity because of its rapid curing rate, energy efficiency, environmentally friendly characteristics, and that it can be used in many fields, which has made it the most sought in the electronic, medical, automobile industry, optics, and packaging industry. When you require solutions in high-performance UV curing, which is innovative and capable of taking care of tomorrow, see what UVET can do.