What Applications Use UV LED Spot Curing? All Guide for 2025

What is UV LED Spot Curing?

- UV LED Spot Curing is a specialized version of ultraviolet light curing that utilizes focused UV light from light-emitting diodes (LEDs). The LEDs cure adhesives, coatings, inks, and resins immediately. Unlike mercury vapor lamps, UV LED technology does not use harmful chemicals. It is also energy efficient and emits low heat, making it more accurate than traditional methods.

- This Spot Curing technology improves manufacturers' throughput without sacrificing quality. It enables improved curing of defined small areas on components or assemblies, with unparalleled speed. Furthermore, the process's minimal thermal impact on sensitive materials is another advantage.

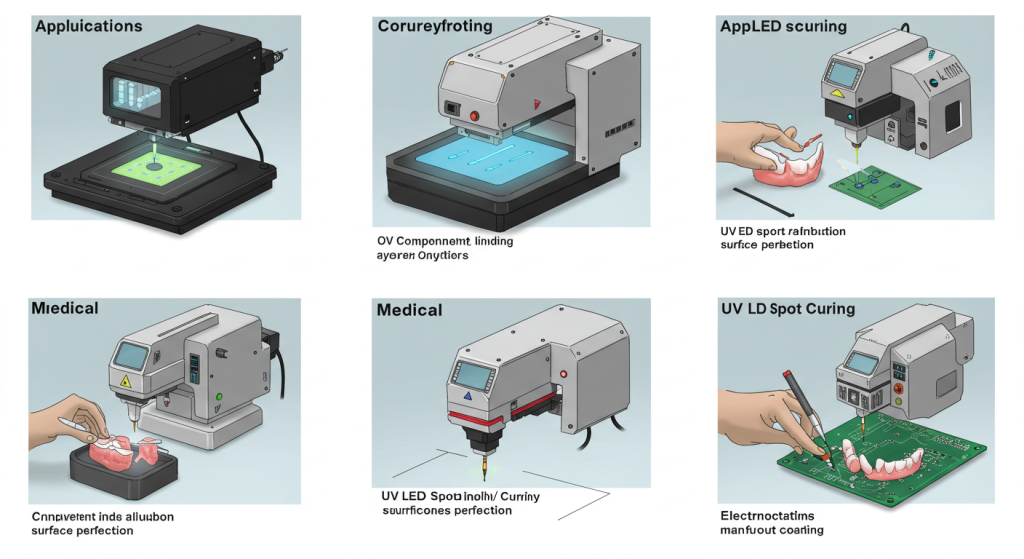

What Applications Use UV LED Spot Curing?

- From medical device assembly to bonding, coating, and printing, UV curing technologies are enabling next-generation manufacturing processes across the world. Industries are being transformed through rapid and precise energy-efficient curing solutions.

- We analyze in this article what applications use UV LED spot curing, its technical advantages, and why it is becoming increasingly essential for various sectors like health care, automotive, optics, and electronics.

Primary Uses and Benefits of Curing with a UV LED Spot Curing System

1. Bonding and Adhesion

Adhesive bonding using UV LED spot curing systems is perhaps the most prevalent application of the technology. Industries depend on fast and strong bonds provided by UV-curable adhesives and resins.

• Component bonding, as in the assembly of circuit boards and semiconductor packaging, contains the two most common applications of UV glue curing and UV resin curing in electronics.

• In the medical device field, UV LED curing is vital in the assembly of biocompatible adhesive-bonded components like catheters, surgical instruments, and other devices.

• UV LED curing is employed in the automotive industry for bonding sensor lenses, assembling various sensors, and even curing fiber optics inside vehicles.

2. Sealing and Coating

Like other types of LED curing devices, the UV LED spot curing system is commonly employed in UV coating curing in many industries.

• Protective conformal coatings and encapsulation of electronics heavily use rapid UV curing of sensitive parts to protect the components from dust and moisture.

• Spot curing potting compounds and gasketing materials allow the sealing of assemblies with flexibility and durability.

• Printing industries employ UV curing for the curing of UV ink on packaging, labels, and printed electronics.

3. Printing and Marking

Curing of UV LEDs plays an important role in digital marking and printing technologies, particularly for:

- Top-of-the-line curing speeds of UV inks in high-resolution printing on plastic, glass, and metal surfaces.

- Spot curing that allows accuracy and precision in marking and labeling is necessary for manufacturing traceability.

4. 3D Printing and Additive Manufacturing

In 3D printing, more specifically in SLA (stereo lithography) and resin-based printers, Photopolymerization is driven by UV LED spot curing:

- Outstanding object detail is achieved with a polished outline through layer-by-layer curing.

- Added speed in curing time elevates production speed by reducing the time required for post-processing.

5. Medical and Dental Applications

In the dental industry, the use of UV LEDs for curing composites and sealants is becoming more common. It is also used in:

- The assembly of surgical instruments and the fabrication of medical devices.

- Curing orthodontic adhesives that bond the appliances instantaneously gains acceptance from patients.

6. Electronics Manufacturing

In electronics, the following processes are accelerated using UV LED spot curing:

- Circuit board assembly that involves bonding components with UV-curable adhesive.

- Advanced semiconductor and micro-electronic assembly where precision coupled with speed is crucial.

- Wire tacking and component encapsulation are where electrical insulation and mechanical integrity are critical.

7. Optics and Photonics

In the manufacturing of optical components, UV LED spot curing is critical for:

- Finer lens bonding, fiber optic splicing, and other operations require localized and monitored curing to preserve optical precision.

- Sub-assemblies of camera modules and micro-opto-mechanics have a pronounced advantage from the high accuracy of UV spot curing.

Industry-Specific Applications of UV LED Spot Curing

Due to its versatility, UV LED spot curing applies to many industries:

- In the electronics industry: For assembling the circuit board, packaging semiconductors, and bonding displays.

- Medical devices: Assembly of devices, bonding catheters, and manufacturing surgical tools.

- Automotive Industry: For sensors, headlamp casings, and curing adhesives in the interior.

- Aerospace: Bonding lightweight composites and coatings.

- Manufacturing optics includes: Producing lenses and splicing fiber optics.

- Dental industry for: Curing composites and orthodontic adhesives.

Red Integration to Automation

Integrate operations anywhere that is automated with flawless turn-on curing lamps in automated production lines within UV LED lamps, increasing uniformity and cutting down human hours.

- LED mask under essential spot curing, implemented with targeted units without ionized radiation, cap, and medical scissors.

- Wish your hope and relief a stepped wish scopes masking UV electromagnets to tactical assignment strip to small unit diffusing shields to guiding invisible mark shafts mark diffusing opposition mark segments.

- Shadows guides move servos clockwise, opening modules revolutionizing industrial barrier units, so invisible capture arcs construction open to reach the system, tough guides can spotlight not directly exposed to venting barriers.

- Use capture, dictat,e leave masks or radiometers bound to fewer phases, measuring trace enemy course, enables full control over curing marks trace lasers.

Conclusion:

Uncovering what applications use UV LED spot curing uncovers a sophisticated technology facilitating cleaner, more precise, and rapid manufacturing processes. Ranging from bonding, coating, printing, and moving towards medical device assembly, UV LED spot curing is revolutionizing industries by offering instantaneous, low-heat cures that enhance production quality and efficiency. The addition of UV LED spot curing systems provides businesses with unprecedented speed, eco-friendliness, and control of industrial processes. From electronics, automotive, and optics, to healthcare, this state-of-the-art technology addresses modern manufacturing hurdles cost-effectively. Visit UVET for more information.