What are the Advantages of Spot UV LED Curing? Fast & Durable

What are the Pros of Spot UV LED Curing?

Manufacturing and printing industries are always changing and evolving: among these transformations, one that stands out is Spot UV LED curing. LED Spot UV curing: what is so captivating about it? What are the advantages of spot UV LED curing? On the off chance you are still weighing its advantages, this grinding of text will help enlighten you about the prospects, technology, and application of LED spot UV curing, as well as make it clear why numerous industries are inclined towards adopting this technology.

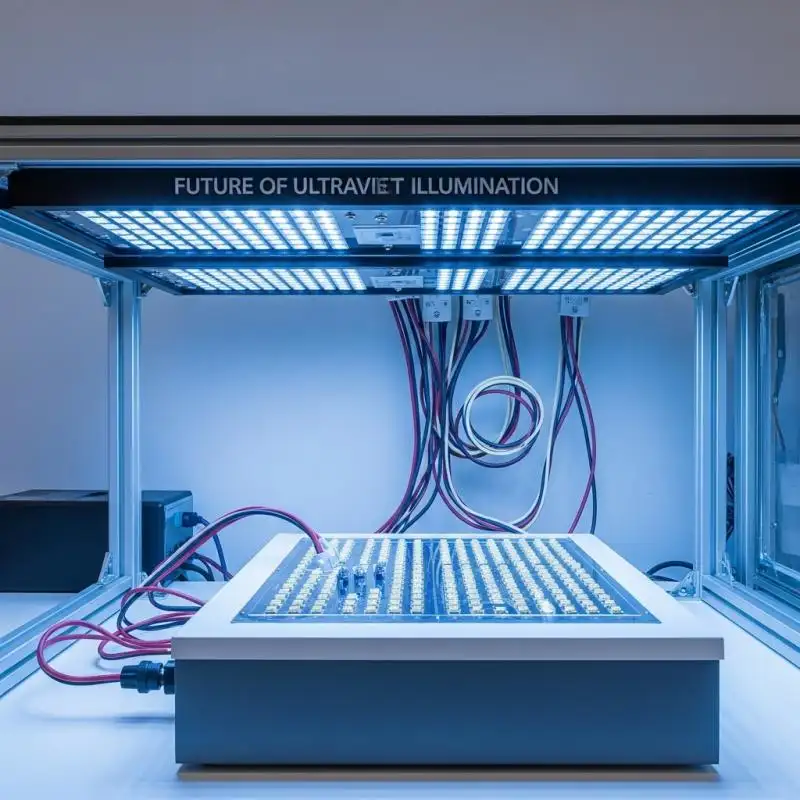

Investing in Detailed Discussion of the Technology of Spot UV LED Curing

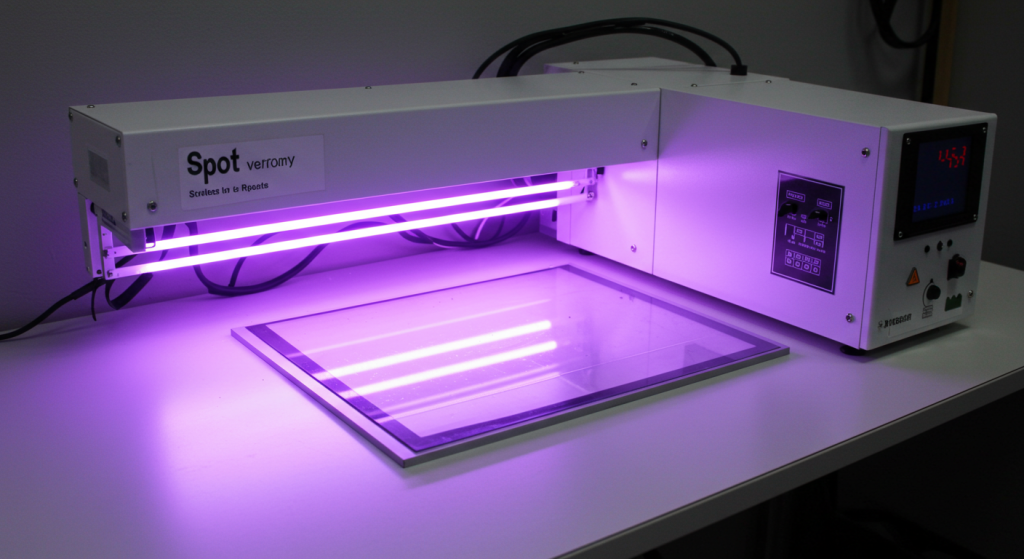

Like any other technology, achieving optimum results with it requires a thorough understanding of its intricacies. So let us first explore what are the advantages of spot UV LED curing. In the broader context, as the name suggests, it is a process that involves curing a specific area of a substrate, ink or coating with Ultra Violet (UV) light-emitting diodes (LEDs) and focusing on a small targeted area on the UV lamp containing an indicator showing the level of UV light intensity. The curing itself is done by LEDs.

Core Advantages of Spot UV LED Curing

1. Increased Productivity and Speed

The advantage of spot UV LED curing with maximum effect is its unparalleled curing speed. The instant-on/off feature of the technology eliminates warm-up and cool-down periods of traditional lamps. As a result:

• Curing time is exceptional at a few seconds or less, which is the dry time for fast-tracked production turnaround.

• Throughput and utilization of machines increase.

2. Energy Efficiency and Cost Savings

The most distinguishing characteristic of spot UV LED curing is energy efficiency. The operation uses 70-80% less electricity relative to conventional UV curing systems, which translates to monetary savings over time.

Other Benefits Include:

• With more than 10,000 hours of lifespan, LEDs don’t require frequent bulb changes.

• Maintenance costs are reduced with LED’s solid-state design.

• Precise spot curing (no overspray or excess coating) results in less material waste.

• Removal of spray powder use results in decreased consumable costs.

3. Print Quality and Outstanding Durability

Spot UV LED curing enhances product strength and adds to its already visually appealing features. Thanks to consistent and uniform curing of paints and coatings, these are achieved:

• Sturdier scratches and abrasions

• Stronger chemical resistance

• Enhanced elasticity, strong, and hard cured layers

• Smooth surfaces with bubbles and no imperfections

• Supplemental gloss and tactile effects

4. Environmental Benefits and Sustainability

Compared to traditional methods, the Spot UV LED curing system is more environmentally friendly for several reasons:

• Problems with hazardous waste lamp disposal are solved since Spot UV curing does not employ mercury lamps.

• Reducing ozone depletion improves general air quality, safety, and health in the workplace.

• There is a reduction in the emission of Volatile Organic Compounds (VOCs), which contributes to a healthier environment.

• Reduced carbon footprint due to more efficient operations.

• Greater material savings from Spot curing since less area is cured.

5. Versatility and Flexibility

Spot UV LED curing is the only method that works with heat-sensitive substrates such as plastics and films. The risk of substrate distortion is minimized due to the lower heat emitted by LED UV lamps compared to other lamps.

Adaptability also applies to the following:

• Printers of all kinds (flexor, offset, digital) can use it as it is multipurpose.

• Using different UV wavelengths (365nm, 385nm, 395nm, and 405nm) allows for specific curing needs.

• The degree of curing thickness for matte and gloss textures can be set to any level.

• Went on to be integrated into state-of-the-art automated production systems

The Mechanism of Spot UV LED Curing: Diffraction Insights

Spotlight LED curing uses photoinitiators in UV ink or coating to activate elements within certain frequency bounds of light emitted by the LED sources. Light, in this case, causes a chemical reaction that polymerizes, which instantaneously locks the material in place. Unlike curing slot die coating, LED UV lamps cure coater strands in a specific spot. Instead of emitting full sheet UV light, they emit narrow bands of UV light on the precise area needing curing. This leads to:

• Greater substrate thermal tolerance.

• Higher energy efficiency due to less exposure.

• More precision in the depth of curing and surface finish.

The most advanced systems incorporate radiometers along with light guides of homogeneous irradiance distribution and leveling of flood lighting to guarantee the desired results are achieved without flaws in the form of faults.

Applications of Spot UV LED Curing in Various Sectors

- Printing within Packaging

Spot UV LED curing enhances both the tactile and aesthetic qualities of packaging, making it more appealing. This is used by brands for logo engraving, adding textures, and striking etchings for better appeal and consumption.

- Printing of Labels

Cured spot LED UV labels offer quicker curing processes, increased durability, and enhanced gloss, and the curing makes it possible to work with diverse materials like shrink sleeves and flexible films.

- Digital and Commercial Printing

Due to the benefits of high-speed curing, commercial printers can increase output and still maintain the quality and standards of the work produced. Spot LED UV curing is also featured on digital presses, as custom finishing and embellishing are available.

- Graphic Arts and Specialty Textures

Embellished designs result from spot UV LED texturing, which they used to derive gloss textures, embossing, and other competitive market finishes.

Main Points From Why Choose Spot UV LED Curing

In case you are still asking why to choose spot LED UV curing, this will give quick hippocampal joggers to get your thoughts together:

• Increased productivity through elevation in curing speed and throughput.

• Cost reduction through conservation of energy, reduced maintenance, and fewer consumables.

• Quality improvement by increased durability, surface perfection, and better gloss.

• Support for sustainability because there is no mercury, and ozone is said to be diminished in the environment.

Conclusion

UV-led curing technologies are becoming the ones that the rest of the industry follows in terms of guiding advancement in UV-led technology. The speed and quality with which tasks are done and their outstanding environmentally friendly ness improves efficiency in accomplishing tasks using less energy, time, and resources, thereby redefining all tasks to the phrase, “print and forget.” Visit UVET now for specialized advice and superior technologies related to UV LED curing.