What Industries Use UV LED Curing? Key Industries & Solutions

What Industries Use Curing With UV LED Lights?

The UV LED curing technology has changed many industries by providing a quicker, cleaner, and more energy-conscious method of curing inks, coatings, and adhesives. This article will explain what industries use UV LED curing? Its applications, benefits, and how it affects modern manufacturing processes.

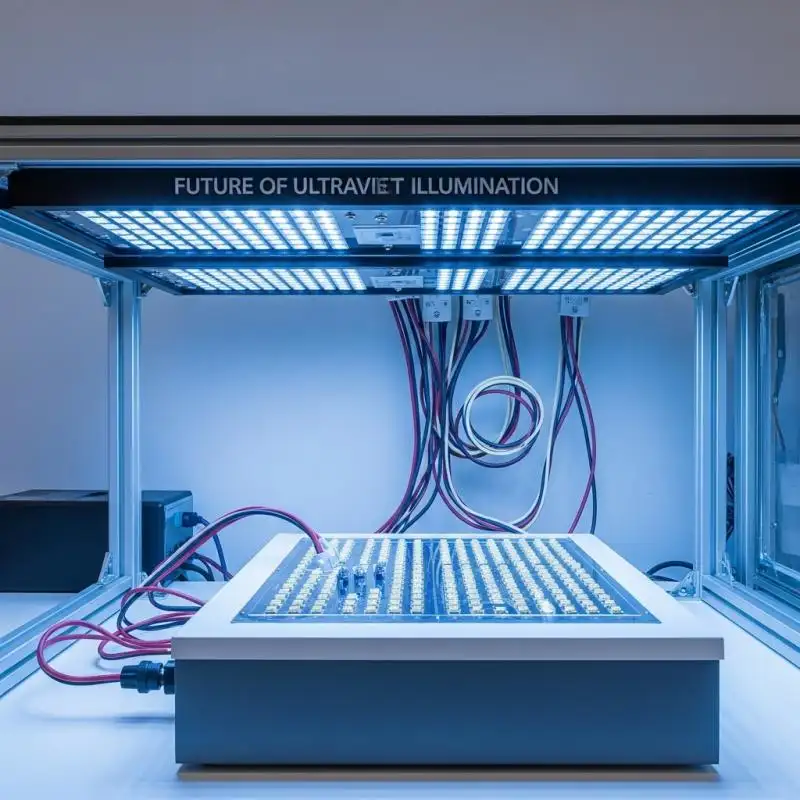

What is UV LED Curing?

UV LED curing makes use of light-emitting diodes that emit ultraviolet light (UV) to perform photopolymerization - a process that chemically cures inks, adhesives, or any substance in a split second. Unlike the older UV lamps that have mercury in them, UV LED systems have specific wavelengths (usually 365nm - 405nm) that enable accurate curing and don’t produce a lot of heat. It is free of mercury, saves energy, and is safe to use on sensitive substrates that cannot withstand heat.

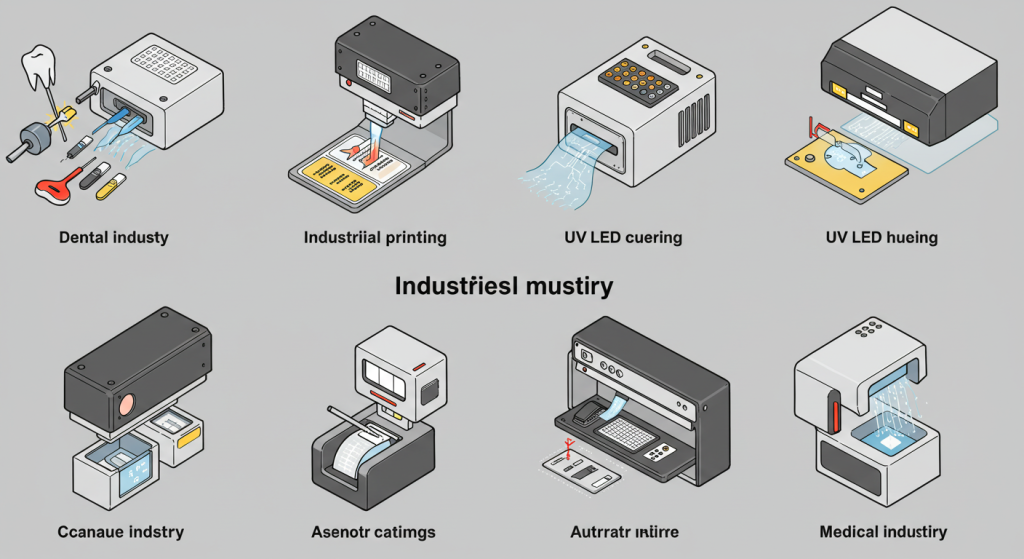

Key Sectors Adopting UV LED Curing Technology

Printing and Packaging

UV LED curing is the first to be adopted in the printing sector, making the whole industry reap the benefits from quick curing times and the versatility of substrates. Its major applications include:

• Digital Printing: Improvement of drying time and overall print quality

• Flexographic Printing (Flexo): High speed means high volume, so better adhesion yields.

• Screen Printing: Curing precision on a variety of materials.

• Label and Package Printing: Tough coatings on labels and flexible packages.

• 3D Printing: Layered curing for fast prototyping.

Electronics Manufacturing

In the electronics field, UV LED curing is useful in:

- Assembling PCBs by curing the conformal coatings and adhesives.

- Component Bonding: The meshing of tiny components with UV LEDs.

- Potting and encapsulating: Shielding delicate components from outside influences

- Manufacturing Mobile Devices and Touchscreens: Bonding and coating are done during the build-up stage.

The devices’ minimal thermal output is beneficial to delicate electronic components, making them more reliable and performing better strategically.

Automotive Industry

In the manufacturing of vehicles, UV LED curing is used for:

- Coatings: Scratch-resistant glossy surfaces.

- Bonding: Attaching sensors, displays, and other parts with strong glue ' adhesives.

- Fillers: Sealing joints of areas that need to be water-tight and incredibly strong.

The streamlined energy-saving curing processes improve the production lines, increase overall effectiveness, and efficiency.

Medical Device Manufacturing

In the medical field, UV LED curing is extremely important for:

Surgical bonds: Used for building up catheters and troublesome syringes.

Coatings: Adding antimicrobial and protective substances.

Sterilisation: UV-C is the most popular version, but UV A/B helps in some curing processes.

For the strict standards placed in the medical field, this technology is helpful because it’s clean and precise.

Wood and Furniture Industry

UV LED curing contributes to wood and furniture manufacturing by:

• Wood Coatings: Excellent finishes for furniture and woodwork.

• Furniture Coating: Rapid curing for mass production.

• Fine Instrument Finishing: Protective coating for fine musical instruments.

Due to low heat emissions, wooden materials do not warp, and their integrity is preserved.

Flooring Industry

For flooring, UV LED curing is used in:

• Vinyl and Wood Flooring Coatings: Durable and glossy coatings.

• Rapid Curing: Speeding up production lines and reducing idle time.

It enhances consistency and increases the quality of flooring products.

Glass and Optical Industry

In this industry, it is used for:

• Glass Coating: Anti-reflective and protective coatings.

• Adhesive Bonding: Seating of components in optical devices.

• Lens Manufacturing: Coating curing on spectacle lenses.

UV LED curing enables control precision that is important for UV optical performance and clarity.

Aerospace and Defense

For aerospace and defense, UV LED curing is used for:

• Bonding and Sealing: Subassemblies of parts with great precision and reliability.

• Coating Applications: Extreme condition surface protection.

These industry standards for robust efficiency technology are used and sustained.

Specialty Applications

The following are some of the specialty areas where UV LED curing is also used:

• Making IDs and Credit Cards: Curing designs and coatings on cards.

• Metal Decoration: Putting decorative finishes on metal parts.

• Coating of Fiber Optics: Safeguarding the fiber optical cables.

• Jewellery Making: Accurately bonding parts together.

These areas make use of the technology's speed, precision, eco-friendliness, and many other advantages.

Benefits of UV LED Curing

The versatility of applications in industry can be attributed to refined processes enabled through automation, which is used worldwide. One of the benefits of UV LED curing technology is the operational costs because it allows for automation. Curing systems using UV LED can be set and operated remotely. Achieving targets with the aid of modern industrial systems that are more than 85 per cent efficient, and in terms of energy consumed, compared to mercury-based UV curing systems, is remarkable.

- Moreover, there’s no need to use toxic mercury when using UV LED, and this lowers the emission of volatile organic compounds (VOC). Due to this, safer and healthier working conditions are provided, which makes a positive impact on the environment.

- Production lines can now supply goods more abundantly because the curing procedures enhance the processor's efficiency by eliminating drying waiting times, thus increasing throughput. This guarantees minimal waiting time, further enhancing manufacturing efficiency.

- Because of their low heat output, UV LED systems are perfect for curing sensitive materials like wood, plastics, and electronic components because they don’t cause warping or degradation of the material.

Due to their compact size, UV LED units can be easily added to most automation systems without consuming too much space, even in cramped areas.

Why Do Industries Choose UV LED Curing?

Industrial adoption of UV LED curing technology is not just for convenience. It is driven by powerful economic and technical factors.

• Energy-efficient UV Curing: This is one of the most powerful claims regarding the use of UV LED curing. Compared to older mercury arc lamps that burn a lot of electricity and generate a great amount of heat, UV LED systems consume much energy. This not only means cooler operation, which is essential for heat-sensitive substrates, but also drastic savings in electricity, greatly lowering operational costs and carbon footprint.

• Eco-Friendly UV Curing / Reduces VOC Emissions Curing: The use of UV LED technology improves Eco-friendliness by eliminating hazardous waste from mercury lamps. Additionally, UV curable materials are usually low VOC (volatile organic compounds), which improves air quality and promotes better working conditions. This perfectly aligns with the recent trend towards sustainable manufacturing curing.

• Instant Curing Technology/Faster Curing Solutions: The speed of curing is remarkable with UV LED. The materials are cured almost instantaneously when exposed to UV light, and soothing treatment is often immediate. This instant curing technology mitigates bottlenecks, significantly improves throughput, and ensures parts can be instantly handled or further processed.

• Lower Heat UV Curing: Due to the very low levels of infrared radiation emitted by UV LEDs, the heat generated is very little. This is important when using thin plastics, films, or delicate electronic parts as substrates since they are heat sensitive, avoiding shrinkage, warping, or other damage.

Conclusion

With its focus on efficiency, eco-friendliness, and precision, UV LED curing technology is transforming many industries. The widespread adoption across industries demonstrates its versatility and the advancements it provides to modern manufacturing.