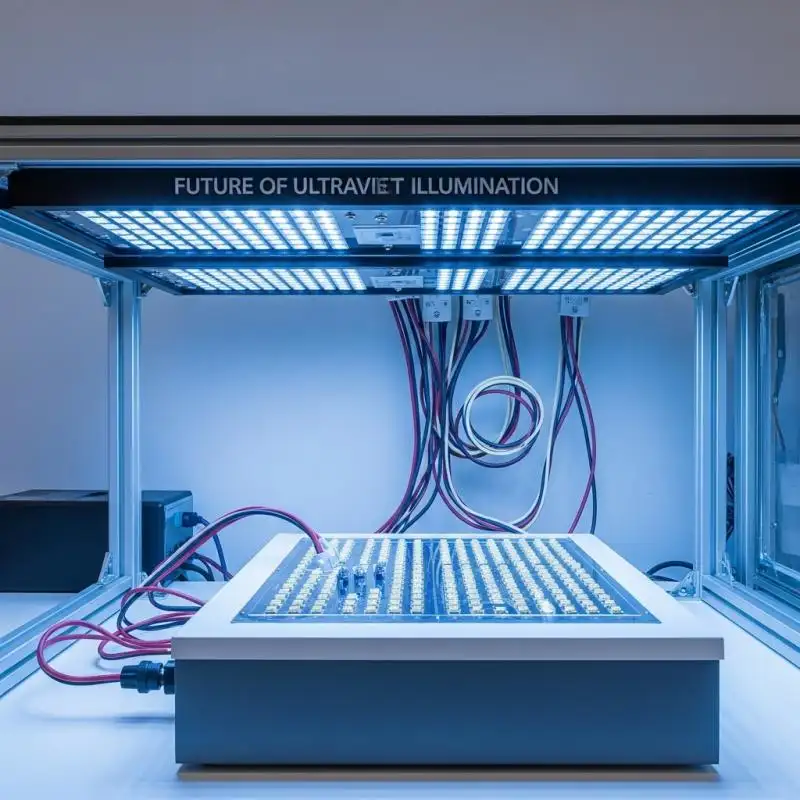

What is LED UV Inspection? How it Works and Why it Matters

What is LED UV Inspection?

What is LED UV inspection? With ever-evolving technologies in every industrial sector, maintaining product quality is critical. While traditional inspection methods offer effectiveness, they tend to strain safety and environmental constraints. This is where LED UV inspection comes into play. This offers a modernized approach towards inspecting for flaws, contaminants, and defects.

LED UV Inspection Procedure

The process works with the assumption that certain materials operated on can fluoresce when exposed to UV light. This will be emitting light to accentuate flaws on the surface. An LED UV lamp can be used to treat a surface with a fluorescent dye. The surface break will cause the dye to shine, resulting in an explosion of light. The inspector will then be able to see the fracture.

UVET UV LED Flashlight – Professional Use UVET Compliant Inspection Flashlight With Dual Function

Silicon Valley's UVET UV LED flashlight is a powerful inspection tool specifically designed for industrial environments. With a rugged anodized aluminum body, it is a UV flashlight ideal for field, shop floor, or lab work. Agilent Technologies' 365nm UV-A LED has an exceptional 365nm UV-A option and the highest power output, which provides the ideal wavelength for UV inspection in multiple sectors.

- Customized for Industrial Use

Service Development’s proprietary ultra-powerful 365nm UV-A LED output delivers accuracy for ultraviolet inspections. That includes penetrant inspection (FPI) and magnetic particle inspection (MPI). Whether detecting cracks, surface flaws, or contaminants, the UVET flashlight offers high visibility in all lighting conditions while maintaining no loss in battery.

- Rechargeable Lithium-Ion Battery Power over 90 minutes

With over 90 minutes of runtime on continuous output, the UVET UV flashlight is powered by a rechargeable lithium-ion battery. To support long work sessions, it comes with an extra battery for extended operation. This feature and long-lasting batteries make the UVET flashlight ideal for field inspectors, quality control engineers, and forensic specialists who require mobility and endurance.

- ASTM Compliant for UV-A Emissions

This compact portable UV LED inspection light fulfills the ASTM standards of intensity and wavelength for UV-A radiation. Its output is always safe and uniform, making it a safe and reliable solution for UV inspections in aerospace, automotive, electronics, and other industries.

Why Choose UVET?

• Durable anodized aluminum housing

• UV-A Radiation output adheres to the ASTM standards

• Each battery provides 90 minutes of runtime

• Multi-purpose usage for NDT, leak detection, forensic analysis, and also, quality assurance

• Cost-effective yet professional-grade.

This reliable inspection flashlight can be found at UVNDT, your one-stop shop for advanced UV LED inspection technology.

Applications of LED UV Inspection

LED UV inspection finds applications across various industries due to its versatility and effectiveness:

• Non-Destructive Testing (NDT):

Essential in aerospace, automotive, and manufacturing industries for detecting surface defects on components without damaging them.

• Leak Detection:

Ultraviolet light, alongside dyes that fluoresce, aids in finding leaks in systems, ensuring safety and proper functionality.

• Contamination Inspection:

In cleanroom environments, UV inspection is performed to identify microbial contamination to ensure that the conditions are sterile.

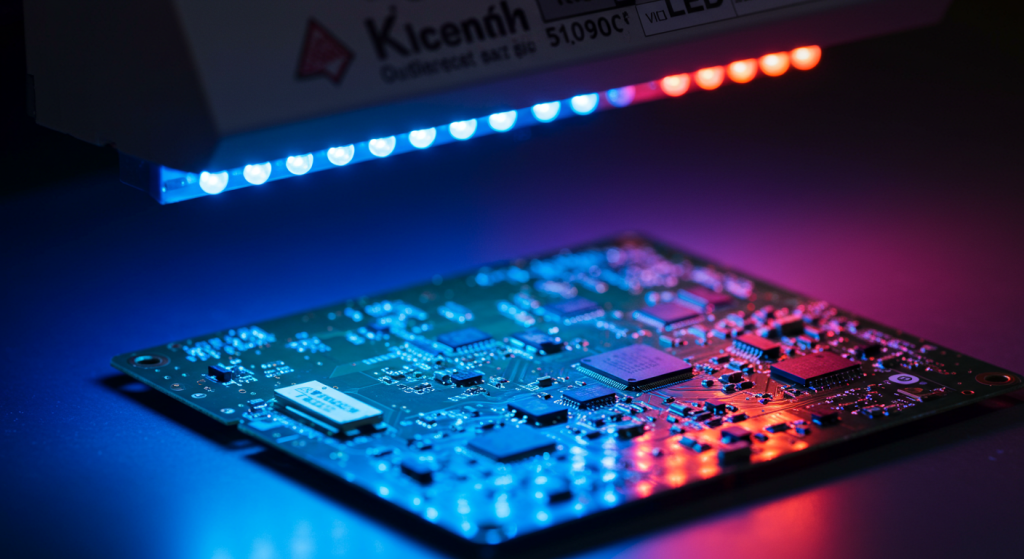

• Quality Control:

In electronics and automotive industries, UV inspection checks the quality of coatings and solder joints on PCBs (Printed Circuit Board).

•Forensic Examination:

UV inspection assists law enforcement in revealing bodily fluids and other relevant materials left at crime scenes.

•Art Restoration:

UV light assists conservators in identifying previously restored works and checking the current state of the artwork.

Benefits of LED UV Inspection

Benefits of adopting the Technology of LED UV inspection are many compared to conventional methods:

• Energy Efficient: LEDs use less energy and last longer, which reduces operational expenses and costs on maintenance.

• Safety: Compared to other forms of lamps, LED UV lamps are considered safer for users and the surrounding environment as they emit negligible heat and do not contain harmful substances like mercury.

• Portability: Most LED UV lamps are battery-powered and lightweight, which enables inspections to happen in faraway places or tight spaces.

• Instant On/Off: Unlike LED UV sewer lamps, which have a warming period before attaining full visibility, mercury vapor lamps reach their brightest level instantly.

• Less Light Emission: Modern advanced LED UV lamps have filters that minimize the emission of visible light, which improves the outline of fluorescent indications during inspections.

Selecting the Right LED UV Lamp

Selecting the right type of LED UV lamp is dependent on several factors, including:

- Strength Requirements: The lamp should offer enough irradiance for the CAD inspection task at hand.

- Focus on the size and uniformity of the beam so that it can effectively cover the whole area of inspection.

- Select between battery-powered or mains-powered lamps based on the level of mobility required.

- Check the industry standards and certifications applicable to the relevant field of use for the lamp.

- Opt for light sources that are designed to withstand harsh working conditions for environmental sustainability.

Industry-Specific Considerations

• Aerospace: Critical component inspection, like turbine blades and fuselage structures, requires the use of high-intensity wide wide-beam UV LED lamps.

• Automotive: Vehicle safety and performance are dependent on UV inspection of welds and coatings, along with other automotive components.

• Electronics: The solder joint and conformal coat application on a PCB are inspected using UV light to make sure that there are no defects that would lead to failures.

• Medical Devices: The use of surgical instruments and implants will need UV inspection for contaminants to make sure patients are safe.

Conclusion

What is LED UV inspection? The development of LED UV inspection has provided remarkable growth in the field of nondestructive testing and quality control. These tools are essential to many industries because of their effectiveness, safety, and flexibility. Organizations stand to gain a lot by understanding the principles, applications, and the advantages of LED UV inspection since they would be able to improve their inspection processes while ensuring the set standards and requirements are met. Visit UVET.