What Safety Gear Do You Need for UV LED Curing?

Protecting your physical health is a fundamental requirement when you operate high-intensity light sources on a production line. While UV LED technology is a significant improvement over mercury vapor lamps, the ultraviolet energy it emits remains hazardous to human tissue.

This guide outlines the essential UV LED curing safety gear you need to prevent ocular damage and skin irritation. By understanding the risks of direct and reflected UV exposure, you can ensure your workspace remains safe while maintaining the high productivity standards of your manufacturing process.

Why Safety Gear Matters for UV LED Curing

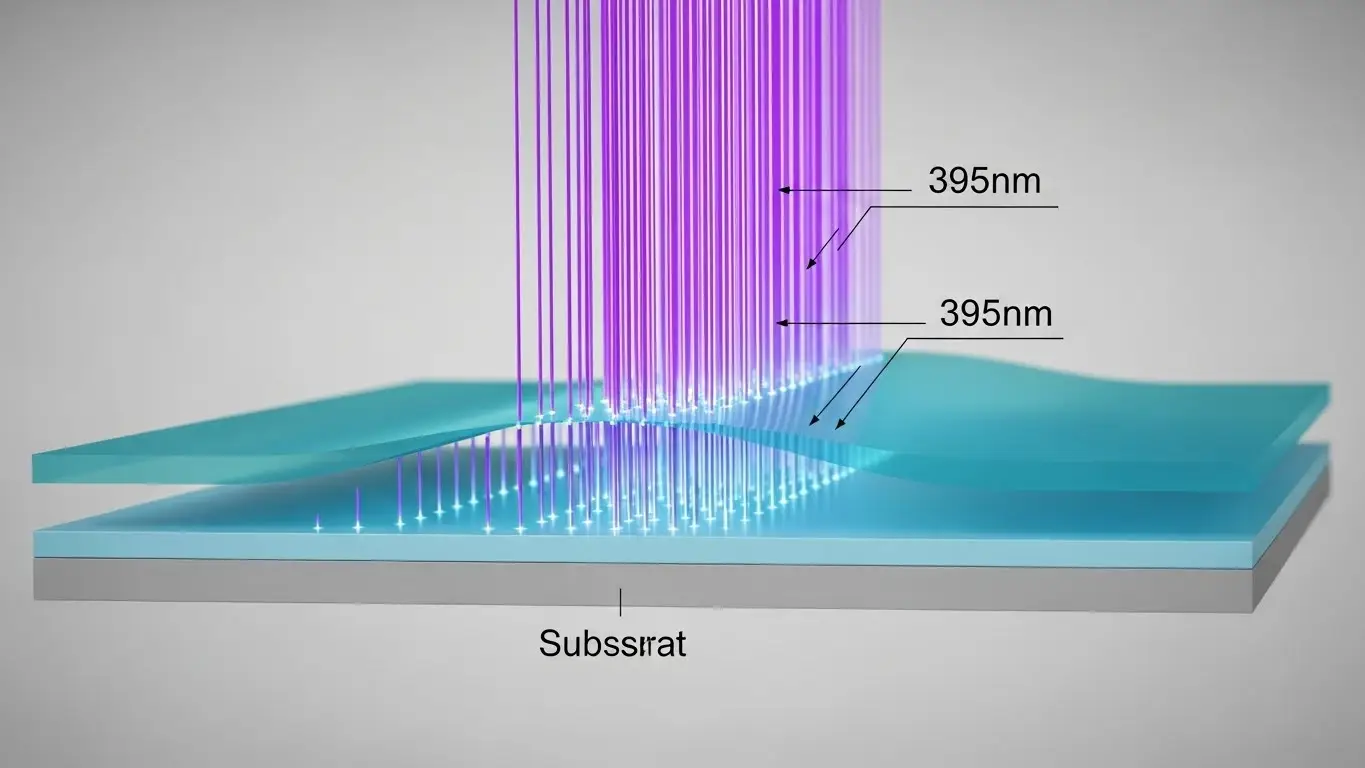

Safety gear matters for UV LED curing because ultraviolet light can damage your eyes and skin if you are exposed without protection. Most industrial systems emit light in the UVA band, typically between 365nm and 405nm, which can penetrate the surface of your skin and reach the internal structures of your eyes.

Even short bursts of exposure from a handheld wand can cause "welder's flash" or painful inflammation of the cornea. Over time, repeated exposure without the right gear increases your risk of chronic conditions like cataracts or permanent skin damage. Your PPE acts as a vital barrier between these high-energy photons and your body.

What Eye Protection Is Needed for UV LED Curing

UV-blocking safety glasses or goggles are essential because they prevent UV light from harming your cornea and retina during curing. You must ensure that your eyewear is specifically rated to block the wavelength your lamp emits.

Standard clear plastic glasses do not always offer full protection against concentrated UV beams. Look for glasses that meet ANSI Z87.1 standards for UV protection and feature side shields to block reflected light that might bounce off metallic workpieces. Comfortable, wrap-around styles are best because they eliminate gaps where stray light could enter your field of vision.

How Should Skin Be Protected During Curing

Skin protection is required when using UV LED curing lights because prolonged or repeated UV exposure can lead to burns or irritation similar to a severe sunburn. You should cover your arms and hands completely to prevent the "erythema" or reddening that occurs when UV photons damage skin cells.

Opaque, nitrile gloves provide an excellent barrier for your hands, while long-sleeved lab coats or work shirts protect your arms. If you work with high-power systems, ensure your clothing is made of a tight-weave fabric that light cannot penetrate. This prevents the cumulative damage that often leads to premature skin aging or more serious long-term health issues.

What Additional Protective Gear Helps With UV LED Curing

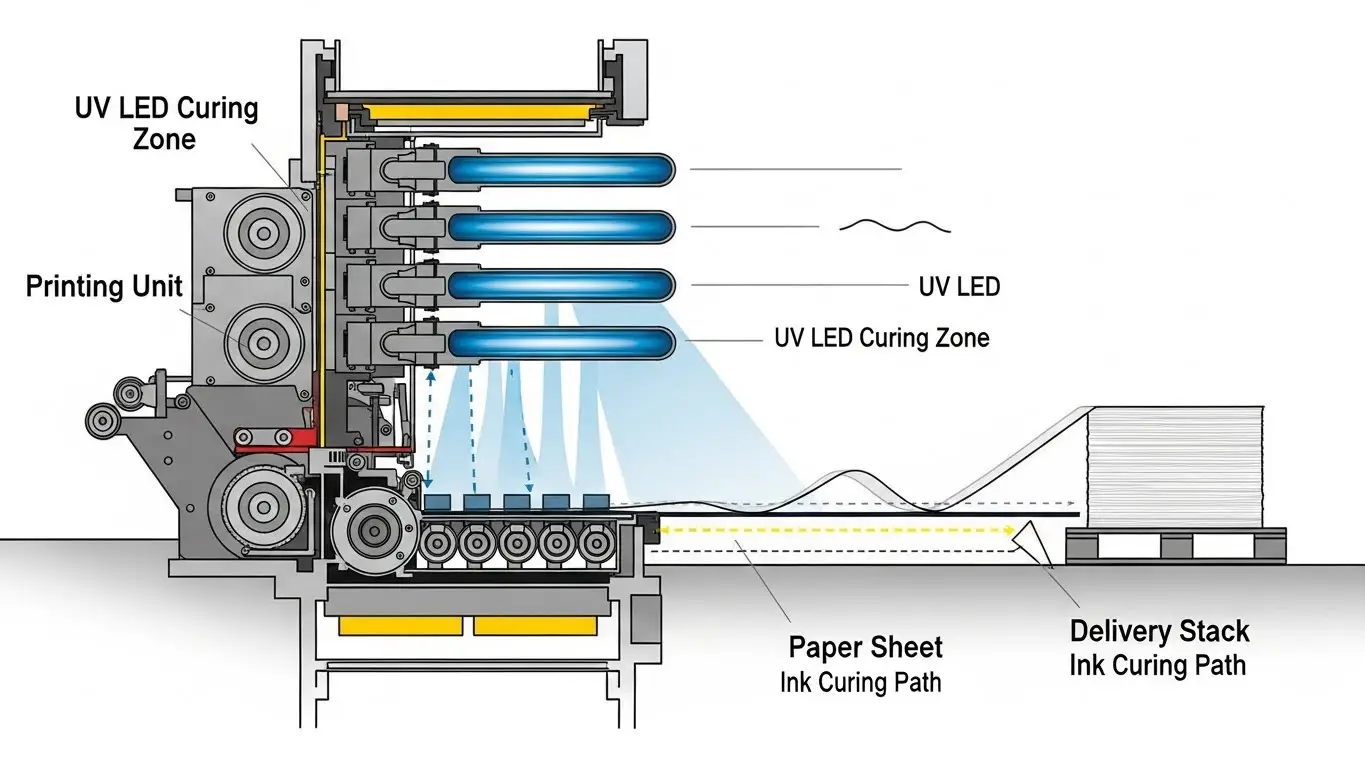

Additional protective gear such as face shields, work shields, and barrier screens can help reduce stray UV exposure and enhance your safety. A full-face shield is beneficial if you are performing manual assembly where your face is close to the light source.

Barrier screens or UV-absorbing curtains are also helpful because they protect other people in your facility who might walk past your workstation. These screens contain the light within a specific zone, ensuring that reflected UV energy doesn't affect anyone outside the immediate curing area. Using these physical barriers reduces the reliance on individual PPE for nearby staff.

How to Use Safety Gear Effectively During UV LED Curing

Using safety gear effectively during UV LED curing involves wearing it consistently, fitting it correctly, and combining it with safe work practices to minimize exposure. You should inspect your gear daily for scratches or cracks that could allow UV light to leak through.

- Avoid Direct Sight: Never look directly into the beam, even while wearing UV-rated glasses.

- Check Your Fit: Ensure your gloves overlap with your sleeves so no skin is exposed at the wrist.

- Use Shielding: Position your workpiece so the light is directed away from your body whenever possible.

- Manage Your Work Area: Label your station with UV warning signs so coworkers know to wear eye protection before entering your zone.

What Are the Key Takeaways on UV LED Curing Safety Gear

The most important safety gear for UV LED curing includes UV-blocking eyewear, gloves, protective clothing, and optional shields to reduce stray light exposure. Your safety depends on the disciplined use of these tools during every shift.

- Eye Protection: Use glasses rated for your specific UV wavelength (e.g., 365nm or 395nm).

- Skin Coverage: Wear long sleeves and opaque gloves to prevent UV-induced burns.

- Area Shielding: Utilize screens to protect yourself and nearby personnel from reflected light.

- Routine Inspection: Replace damaged PPE immediately to maintain a secure safety barrier.

What Types of UV LED Spot Curing Systems Should You Consider for Safety?

What UV LED spot curing systems exist and how can their design protect you? Some UV LED spot curing system models include integrated light guards or foot pedals to ensure the light is only active when your part is in a safe position. You can explore various spot curing options to see which safety features fit your line.

How Do Handheld UV LED Curing Lamps Fit Into Safe Workflows?

How should you use handheld UV LED curing lamps safely? Because these tools are portable, the risk of accidental exposure is higher. Following handheld lamp safety protocols and understanding the lamp's mechanics will help you protect yourself while maintaining mobility.

How Do Wavelength and Exposure Time Affect Safety Gear Needs?

How do the UV wavelength and the duration of the cure change your safety requirements? Higher intensity and longer curing times increase the total UV dose your body could receive. Selecting the correct UV adhesive curing wavelengths also helps you pick eyewear with the right blocking rating.

Are Battery-Operated UV LED Curing Lights Safe to Use?

Do battery-operated UV LED curing lights require different safety gear? Whether you use battery UV LED curing lights or a battery-operated UV LED curing light, the safety requirements for your eyes and skin remain identical to those of tethered systems.

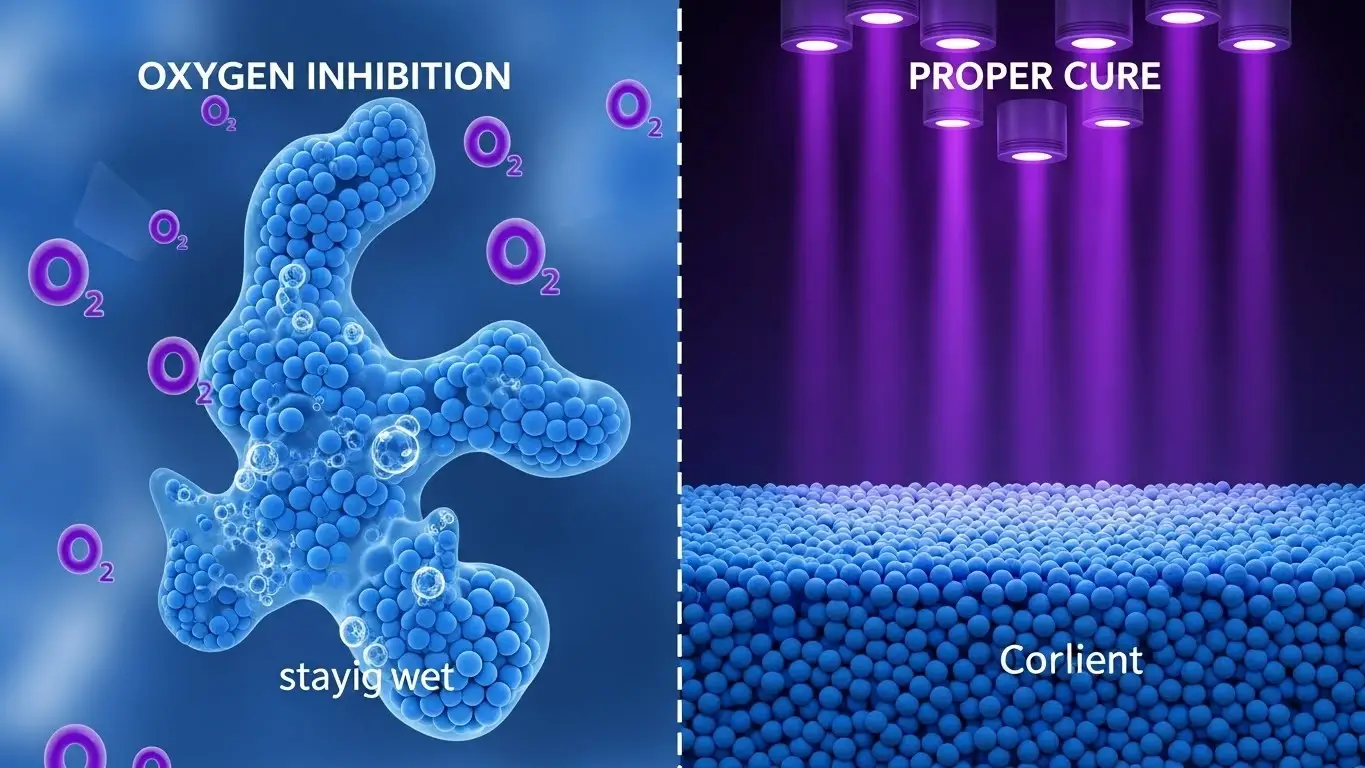

What Is Tacky Cure and Should Safety Gear Change When It Happens?

What is a tacky cure and does it affect your safety practices? If you are troubleshooting a tacky cure, you might be tempted to move closer to the beam or increase exposure time, which requires even stricter adherence to your PPE and shielding routines.

Final Thoughts

Your commitment to safety gear is a commitment to a long and healthy career in manufacturing. While UV LED lamps do not generate the intense ozone or high heat of older systems, their concentrated light output demands your full respect and attention. By standardizing your use of UV-blocking eyewear and protective clothing, you remove the health risks associated with your curing process. Safe habits ensure that your production line remains productive without compromising the well-being of your tea