Which Adhesives are Compatible with Spot Curing Systems?

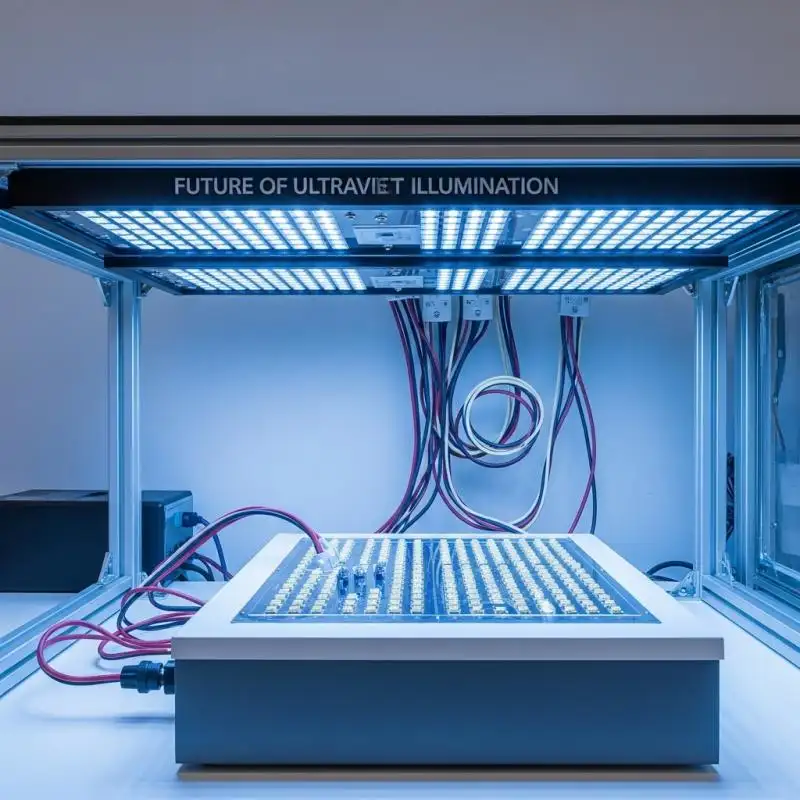

UV LED Spot Curing System - Improved Accuracy and Curing Productivity

- With regards to reducing operational costs and improving productivity at the industrial level, the Ultra Violet LED Spot Curing System takes advantage. The system uses 14W/cm² UV energy efficiently and economically for pulse curing at 365nm, 385nm, 395nm, and 405nm. This results in a thorough coverage of many types of photo-initiated adhesives, LED curable adhesives designed for different materials, and specific thermal and bonding challenges.

- Medical grade devices consist of sensitive polymers, which in most scenarios are considered weak materials. However, instantaneous curing does not pose a challenge with the UV LED Spot Curing System.

- Ultra-rapid production cycles further enable turning a device’s endless cycle of superlative intense heat and ultra-weak pulse curing into a highly efficient adhesive curing process. Low heat emission during the curing process also ensures that these devices do not get damaged. Elsewhere, precision parts assembly turns ultra-rapid, non-touch, residue-free curing into an utmost necessity.

The Integration Accomplished and its Ease of Operation

Because of its unusual configuration, the unit can be plugged into any production line or used as a stand-alone benchtop device. The interface further increases the ease of use of the system as it lessens the training that would be required for new operators and has intuitive operating aids. Such systems are used in many industries like assembling electronics, optical bonding, and manufacturing medical devices.

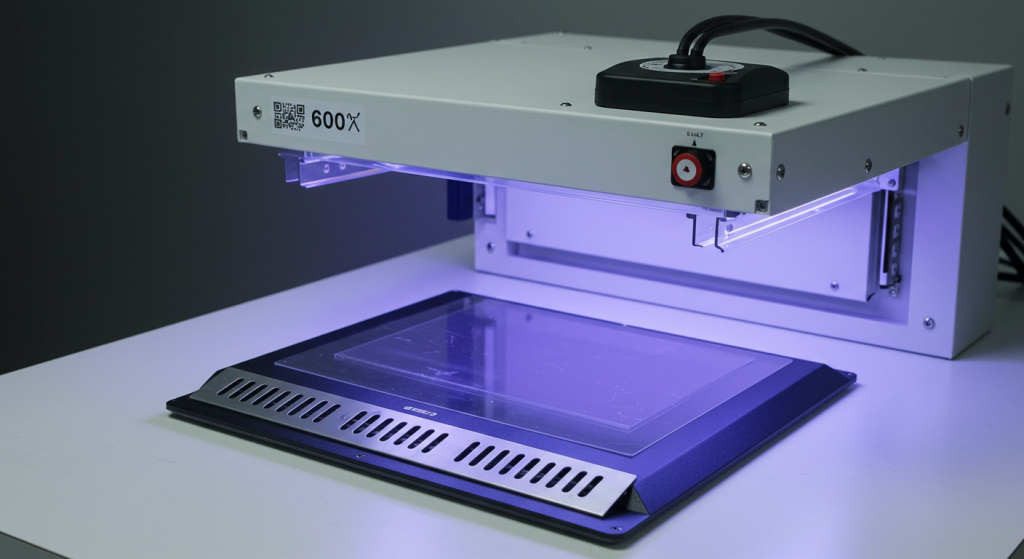

The Most Important Features of the UV LED Spot Curing System

• The Power Controller of the UV LEDs: It controls output power, latching on the UV LEDs to preselected wavelengths and modes of operation, it possesses a port-controlled recallable timer and digital clock, and other ports capable of defining and storing cure time.

• Light guiding (fiber or liquid light guide): The entire guide could differ in terms of single or multi-head guides, length, diameter, and shape, but all can focus ultraviolet light on distinct locations of UV cures, super-fast outpacing what a single spot cure could achieve.

• UV LED Light Head Module: The module holds powerful UV LEDs mounted on it and emits UV light. Accurate placement of the guide and the LED is required, as both the guide and the LED share a portion of the light critical for their function. The stability of results guarantees that the curing light must be on throughout the process.

• Control Methods: Control from outside the system can be done using foot pedals, for example. For simplified external operation control, buttons could be enabled to make effortless control.

Subtypes for Spot Curing Adhesives

Not many adhesives are applicable for spot curing. Below are the leading types of adhesives best geared to the demands of spot curing hardware.

1. UV Acrylic Adhesives

Most of the concern rests on the application of acrylic adhesives since they augment at the time of acrylic spot curing. These adhesives tend to cure almost instantaneously with UV and LED lights, providing amazing structural bonds, notable optical shrinkage, and minimal spatial contraction and psychic energy during the curing. As a result, these adhesives excel in glass and plastics relating to metals, which require precision optic clarity at the boundary of differing materials.

2. UV Epoxy Adhesives

The bonds with exposed epoxy can sustain multiple mechanical strengths alongside impressive thermal resistance, ideal for medicine. Ammun devices and electronics assemble epoxy bonds after a lot of testing due to the strong polymer materials utilized.

3. UV Cyanoacrylate Bonding Adhesives

These bonds will serve in some cases where immediacy in bonding is required, even in spot curing systems. Their formulations permit the formation of bonds at an extremely quick speed without a matte coating of adhesive on surfaces, thus commanding strong bonds on various plastics and metals.

4. Dual-Cure Adhesives

In some assemblies, the geometry of the parts in question gives rise to shadowed areas that block illumination. The second term, dual-cure adhesives, is used to indicate light curing with another curing method, like heat or moisture. Concealed joints meant for micro-assembly and other critical microdevices are the joints of medical gadgets that stand out most among dual-cure adhesives.

What Measures are Taken in the Steps Involved in the Process of Curing Adhesive Activation?

- Photoinitiators are already present in the constitution of adhesives suitable for spot curing. These are compounds activated with light-sensitive wavelengths working at specific levels.

- They can complete the polymerization process of adhesives, completely setting the bond, within seconds of exposure to ultraviolet or visible light.

- Modern LED curable adhesives use 365nm and 405nm light sources, which emit less heat and consume significantly less energy than traditional broad-spectrum UV lamps.

Benefits of Spot-Curing Adhesive

Consider the following benefits of using spot-curing adhesives:

• Bonds can be formed in seconds. The adhesives can be cured instantly.

• Environmentally friendly and user-friendly due to the absence of solvents in the formulation.

• Delicate optical joints are preserved, while bonding glass and optics requires sensitive applications.

• Strong and resilient bonds unaffected by environmental conditions are provided.

• Low biocompatible bonds are essential for assembling medical devices.

• The robots stop for breaks, as the low bond temperature bids protect the heat-sensitive substrates.

• Dispensing, as it relates to the assembly line, is done with precision, as it occurs in robotic arms.

Sensors Using the Optics Applications

The most advanced spot-curing systems for the application of which adhesives are compatible with spot curing systems can be found in the following fields:

• Medical devices are comprised of surgical-grade plastic sensors, which are bonded using biocompatible UV adhesives and surgically fastened.

• Bonding in high-temperature operations is performed in the UV acrylic and epoxy fields of microelectronics and circuit board assembly.

• In optoelectronics, the use of distortion-free, optically clear adhesives for bonding lenses and fiber optics is done with precision.

• Touch curing, also known as spot curing, allows bold yet delicate adhesion of plastic and glass to touch screens and displays.

• Automobile assembly is accelerated by the use of cross-linkable UV adhesives for fast bonding of metal and plastic components.

• Aerospace: In the aviation and aerospace industries, high-strength-to-weight ratio adhesives, as well as thermally stable ones, are essential.

Preferred Practices for Selecting Spot Curing Adhesives

Maintain the balance between the curing system's output and the rate of absorption of photoinitiators in the scope of adhesive bonding. A positive ratio should exist between the photoinitiators and the spot curing system.

• Perform an analysis of the surface and the level of concealment of the substrate material.

• Select the best fitting adhesives in terms of their strength, flexibility, translucence, and based on intended use.

• Observe those areas of the surface that will not be accessible and mark them within the work surface using dual-cure adhesives.

• Balance the rate of curing for the adhesive and the pace of production activities in a sequential manner.

• Get in touch with subcontractors who deal with UV or LED systems for specialized aid.

What Sets Trust UVNDT Apart Concerning Spot Adhesive Curing?

We are available for his integrative or standalone systems industry experts, compatible with curing adhesives and UV LED spot curing systems, enabling us to provide:

• Deal spot curing confidence without comparison.

• Assistance in illuminating “curing” adhesives from all angles comprehensively.

• Solutions to optimize your proposed technologies.

• Enhanced support beyond the advanced technology and timely delivery.

Conclusion

For the high-tech industry, spot curing systems, with which adhesives are compatible with spot curing systems is very important for the bonds to be accurate, economical, and appealing. No device could be considered a proper chemist without a UV acrylic epoxy silicone dual-cure adhesive to some curing device. Adhesives that are light curable, as well as spot curing systems that are used in conjunction with traditional curing methods, are shackled as they allow manufacturability, accuracy, and improved quality delivery to customers. At UVET, we design targeted collaboration for optimal tailored strategies on effective bonding crafted through guided research — we redefine guesswork.