What is wide-format UV printing?

The speed, durability, and high resolution of the prints made over a wide surface have transformed the printing industry all over the world with the introduction of wide-format UV printing. Unlike solvent or latex printing, the UV-curable wide-format printing employs the use of ultraviolet (UV) light to harden the ink immediately on different media, causing the immediate drying process, vivid colors, and outstanding surface durability. Under this progressive process, photoinitiator-containing UV-curable inks are subjected to UV LED lamps or mercury lamps and are polymerized to convert the liquid ink into a solid film. The wide-format UV printers are energy-efficient, eco-friendly, and very versatile in use in the industry by suppressing the use of heat-based drying systems.

Working Principle

Wide-format UV printing is based on a photochemical reaction that is called photopolymerization. The monomers and oligomers in UV-curable inks (CMYK + white and varnish) are in the liquid state when deposited on a substrate, and then they become solid when exposed to a particular UV wavelength, usually 365nm, 385nm, 395nm, or 405nm.

UV flooding, UV flood, or UV LED curing lamp. The UV flood system produces an ultraviolet light, which is reflected off the photoinitiators in the ink to cause a crosslinking reaction. This makes the ink molecules polymerize immediately, creating a solid, scratch-resistant, and fade-resistant image on the surface.

Key Technical Components:

- UV LED Curing Wavelengths: 365-405 nm

- UV Intensity (Irradiance): 6-12 W/cm2

- Print Resolution: 2400 dpi (maximum, depending on the type of head)

- Print Head Technologies: Piezoelectric (Ricoh, Kyocera, Konica Minolta)

- Strength of adhesion to Ink: Metal, glass, wood, and plastics.

- Instant-On UV LED Technology: Guarantees stable curing without heating up.

The technique allows the drying to take place immediately, so that it can be operated continuously without stopping to allow evaporation or the uptake of the chemical, as is essential to high-speed wide-format UV inkjet printing

Technical Benefits of UV LED Wide-Format Printing Systems

Large-format UV printing with UV LED technology has several advantages for its engineering and the environment:

High Energy Efficiency

UV LED is an electrical-to-ultraviolet radiation conversion system that produces ultraviolet radiation with a low production of heat. They do not need as much energy as the mercury lamps, and therefore, lamps and substrates last longer.

Energy conservation: 70 percent of the traditional curing systems.

Power density: 6-12 W/cm2 and constant irradiance.

Instant Start-Up and Cooling

UV curing modules based on LED have instant-on functionality, that is, they do not need to warm-up. This enhances output and reduces idle time in industrial UV printing machines.

Measuring Accuracy and Image Luminosity

The contemporary UV LED flood curing systems offer even distributions of irradiances throughout the curing footprint. Large substrates ensure uniform exposure and high uniformity of curing due to optical lens arrays and calibrated measurements of radiant flux.

Extensive Life and Minimal service

The life of LED UV lamps is normally more than 20,000 hours, providing stable performance and low costs of operation. They are also mercury-free and need minimal maintenance, which aligns with the objectives of sustainability in smart manufacturing.

Applications

The use of wide-format UV printing systems in various industries is very common since it is versatile and can be used on both rigid and flexible materials.

Display graphics and Signage

Most frequently used is in the production of banners, billboards, and POP displays. These prints also have outstanding weather and scratch resistance with UV-curable inks, where the color is kept stable even in severe weather conditions characterized by excessive UV radiation.

Industrial and architectural applications

UV printing on glass, wood, and metal can be used to decorate surfaces on architectural panels, furniture, and car interiors, and is durable. The UV LED large-format printer guarantees a high accuracy of ink adhesion and smooth color mixing on complex materials.

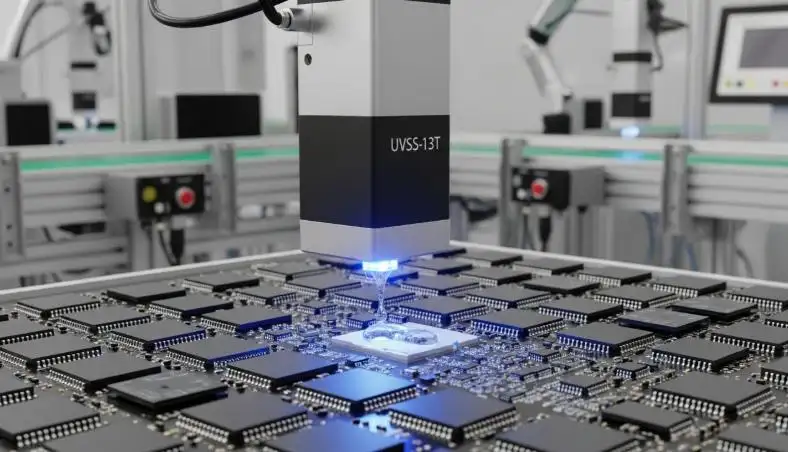

Manufacturing of Electronics and PCB

Electronics UV printing can be used to label, insulate coated and coat PCB accurately. The thermal stress in electronic parts is removed by the instant curing UV process, which safeguards delicate parts.

Packaging and Prototyping

The wide-format UV printing is applied in the packaging of short-run prototypes and decorative designs. Within the UV LED area curing process, vibrant, odor-free, and environmentally friendly outcomes are guaranteed, which is ideal in food-grade packaging.

Carmobile and 3D.

The technology is also applicable to UV printing of automotive parts and 3D surfaces with the use of 3D printing to provide high adhesion and finish on curved or irregular geometries.

The UV LED System 650x20 mm UVET Printing

UVET provides a state-of-the-art UV LED System Printing (650x20 mm) at UVNDT to assist in the industrial wide-format UV curing. The system provides up to 12W/cm2 UV intensity, which makes it fast and evenly cured over a large area of coverage.

Key Features:

Good curing performance: UV intensity as high as 12W/cm2 to cure fast.

Multi-substrate versatile wavelengths: 365nm, 385nm, 395nm, and 405nm.

Adjustable parameters: Adjustable UV intensity and exposure time of several inks.

Broad coverage: 650x 20 mm curing window provides consistency in performance on wide-format prints.

Technical Advantages:

Instant-on UV LED Technology: 0 warming up and cool-down.

Energy Saving: Saves up to 60 percent of power.

Low Heat: Custodians of sensitive materials and heat-sensitive inks.

Stable Irradiance: Provides high polishing of polymerizations with high-resolution prints.

The UV LED area curing system is also a seamless extension of digital, screen, and ink jet printers, offering industrial quality durability and intermittent curing.

Environmental and Economic Impact

UV-curable printing is available in wide-format, with high environmental advantages. UV inks are 100 percent solid and free of VOCs, which means that they do not release solvents to the air, thereby minimizing toxic emissions. Moreover, the power consumption of LED UV systems is lower, waste is less, and no ozone filtration is needed, which is a green solution to the current manufacturing process.

Economically, the prolonged life cycle of UV LEDs and low cost of consumables lead to low total cost of ownership (TCO). Moreover, the immediate curing reduces the turnaround time, making the operations more effective.

Conclusion

Wide-format UV printing is one of the breakthroughs in the technology of industrial printing - accuracy, performance, and sustainability. This technology reinvents the standards of modern printing with its instant-curing format, energy efficiency, and compatibility with a wide range of materials. A good example of this development is UVET 650x20 mm UV LED System of Printing, which has high UV intensity, wide wavelength coverage, and reliable curing throughputs. UVNDT can offer the technology and the expertise needed to propel your production, as manufacturers are interested in high-performance, eco-friendly UV printing solutions.