Air-Cooled vs Water-Cooled UV LED Curing: Which Should You Use?

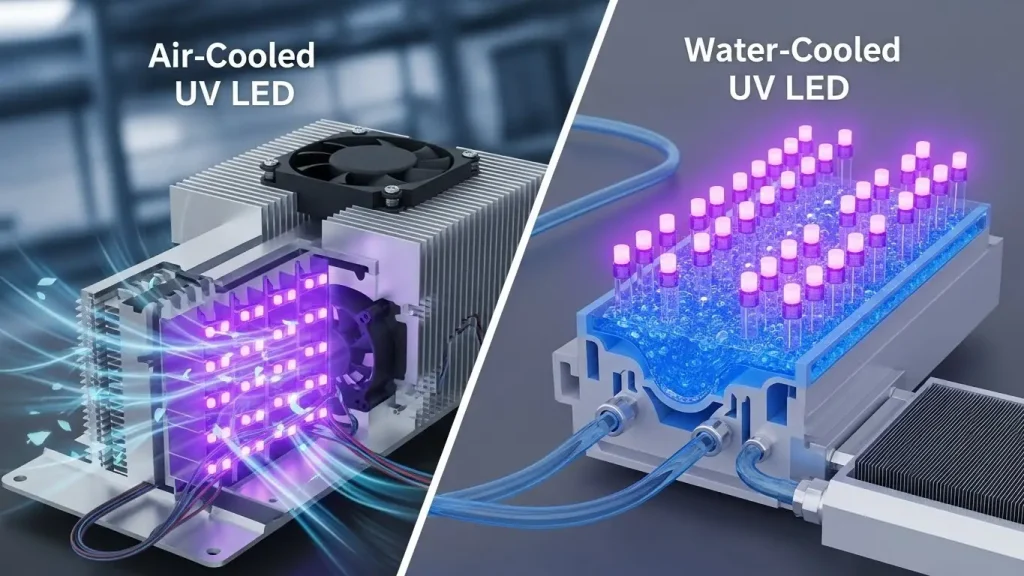

Choosing the right thermal management strategy is essential for maintaining the performance and lifespan of your ultraviolet equipment. You will find that the choice between air-cooled vs water-cooled UV LED systems often depends on the specific intensity requirements of your process and the physical constraints of your production line.

This guide examines how each cooling method handles heat dissipation, the impact on UV output stability, and the practical trade-offs in maintenance and installation. By understanding these technical differences, you can select a cooling approach that ensures your curing process remains reliable and efficient over thousands of hours of operation.

What Is the Difference Between Air-Cooled and Water-Cooled UV LED Curing Systems?

Air-cooled and water-cooled UV LED curing systems differ in how they manage heat generated by the LEDs, with air cooling using airflow and water cooling using circulating liquid to pull heat away. In an air-cooled system, integrated fans blow ambient air across internal heat sinks to dissipate thermal energy. Water-cooled systems, conversely, utilize a closed-loop chiller that pumps liquid—typically a water-glycol mixture—through internal channels in the lamp head to manage the thermal load.

The primary difference lies in heat transfer efficiency, as liquid has a significantly higher thermal capacity than air. This means that while air-cooled units are more self-contained, water-cooled units can handle much higher heat loads produced by high-intensity LED arrays without the risk of thermal degradation. Efficient thermal management ensures that the peak wavelength of your LEDs stays within the required range for your photoinitiators.

What Are the Practical Benefits of Air-Cooled UV LED Systems?

Air-cooled UV LED systems are generally simpler to install, require fewer auxiliary systems, and tend to have lower upfront costs, making them suitable for many general-purpose applications. You do not need to worry about plumbing, external chillers, or the risk of liquid leaks near your electronic components. These systems are often "plug-and-play," requiring only a power connection to begin operation, which simplifies the integration process on existing conveyor belts or manual workstations.

Their compact and self-contained design is ideal for facilities with limited floor space where an external chiller unit would be impractical. Because there are no liquid pumps or complex fluid filters, the daily maintenance routine for an air-cooled system is usually limited to checking the intake fans for dust or blockages. For lower-intensity applications where the heat load is manageable, air cooling provides an excellent balance of performance and ease of use.

What Are the Practical Benefits of Water-Cooled UV LED Systems?

Water-cooled UV LED systems excel in dissipating heat more efficiently, enabling more stable, higher-intensity operation and making them well-suited to demanding, continuous-use environments. Because liquid cooling maintains a very narrow temperature range at the LED junction, you can drive the diodes at much higher power levels than would be possible with air. This results in a higher peak irradiance ($W/cm^2$), which is often necessary for high-speed printing or deep-penetration industrial adhesives.

Water cooling is also inherently quieter because it eliminates the need for high-RPM fans at the point of cure. This is a significant advantage in cleanroom environments or small workspaces where noise pollution must be minimized. The ability to keep the lamp head at a constant, chilled temperature also prevents heat from radiating onto your substrates, protecting heat-sensitive parts from thermal distortion during long production runs.

How Do Cooling Choices Impact Performance and Output?

Cooling strategy influences how consistently a UV LED curing system can maintain intensity and uniform output, with better thermal control tending to support higher performance. You will notice that as LED chips heat up, their efficiency drops, causing the UV output to "drift" or weaken over time. Water cooling virtually eliminates this drift by maintaining a constant thermal state, ensuring that the first part cured in the morning receives the same energy as the last part cured in the afternoon.

Air-cooled systems can experience thermal decay if the ambient air in your facility is hot or if the filters become clogged with debris. This can lead to a drop in UV intensity of up to 10%–15% over the course of a shift if not properly monitored. For processes with narrow quality windows, the superior thermal stability provided by liquid cooling is often the deciding factor in ensuring every part meets specification.

What Are the Typical Trade-Offs Between Air-Cooled and Water-Cooled Systems?

Choosing between air-cooled and water-cooled systems involves trade-offs such as simplicity versus cooling efficiency, footprint differences, and varied maintenance needs. With an air-cooled system, you trade away the highest intensity levels for a smaller total footprint and lower maintenance complexity. In contrast, a water-cooled system provides maximum power and stability but requires you to manage an external chiller, fluid levels, and periodic coolant flushes.

- Cost: Air-cooled systems have a lower initial purchase price; water-cooled systems require investment in a chiller.

- Footprint: Air-cooled lamp heads are often larger to accommodate fans; water-cooled heads are compact but require floor space for the chiller unit.

- Maintenance: Air systems need fan/filter cleaning; water systems need chiller maintenance and fluid monitoring.

- Reliability: Water cooling protects LEDs better under high-load conditions, potentially extending diode lifespan in industrial settings.

How Should You Decide Which Cooling Approach to Use?

Deciding between air-cooled and water-cooled UV LED curing systems involves evaluating factors like production speed, thermal loads, environmental conditions, and long-term stability needs. You should start by determining your required peak irradiance; if your process demands more than 16–20 $W/cm^2$, water cooling is typically necessary to prevent the diodes from overheating.

- Assess Your Intensity Needs: High-power applications usually dictate water cooling for safety and output stability.

- Evaluate Your Environment: Hot or dusty environments may cause air-cooled systems to fail; water systems are isolated from ambient air.

- Check Physical Constraints: Determine if you have the space for an external chiller or if a self-contained air unit is required.

- Analyze Production Duty Cycle: Continuous, 24/7 lines often favor the reliability and thermal consistency of water cooling.

- Review Substrate Sensitivity: If your substrate is extremely heat-sensitive, the lower radiant heat from a water-cooled head is an advantage.

What Common Misconceptions Exist in Cooling Choice?

Common misconceptions about cooling choices include oversimplified notions that one approach is universally better, without considering application context or system design. You might hear that "water cooling is always better," but for many low-to-medium power applications, air cooling is perfectly sufficient and far more cost-effective.

Another myth is that air-cooled systems are "noisy and unreliable"; modern high-quality air units use intelligent fan control to minimize noise. Finally, some users believe that water-cooled systems are "leak-proof" by default. In reality, liquid systems require proper hose management and regular inspections to prevent accidental spills.

What Are the Key Takeaways on Air-Cooled vs Water-Cooled UV LED Curing?

The choice between cooling methods is a technical decision that must be aligned with your specific intensity requirements and production environment. Air cooling offers simplicity and low cost for standard tasks, while water cooling provides the stability and power needed for high-demand industrial processes.

- Air-cooled systems are best for low-to-mid intensity and space-constrained areas.

- Water-cooled systems are essential for high-intensity, continuous industrial production.

- Thermal stability directly impacts UV output and final part quality.

- Selection should be based on your required $W/cm^2$ and the ambient conditions of your facility.

How Do UV LED Intensity and Irradiance Tell You?

Intensity determines how quickly a cure is triggered. You can learn more about how UV LED intensity relates to your cooling needs on our technical page.

How Is UV LED Dose Calculated?

The energy delivered to your part is a factor of intensity and time. Use our guide to calculate UV LED dose to ensure your cooling choice supports your line speed.

What Affects Uniformity in UV LED Curing?

Maintaining a flat intensity profile is harder if the lamp head is overheating. Review what affects uniformity to see why thermal management is critical for consistent results.

How Does Lamp Temperature Affect Performance?

Excessive heat causes diode output to decay over time. Read about the relationship between lamp temperature and performance to understand the physics behind cooling choices.

What Maintenance Should You Plan for UV LED Curing Systems?

Different cooling methods require different upkeep routines. Check our maintenance guide to prepare your team for the specific needs of air or liquid cooling.

What Should You Know About Water-Cooled UV LED Systems?

If you are leaning toward liquid cooling, you need to understand the chiller requirements. Explore our details on water-cooled UV LED systems for a deeper look at the hardware.

What Should You Know About Air-Cooled UV LED Curing Lights?

For many, the simplicity of air cooling is the deciding factor. View our overview of air-cooled curing lights to see if they fit your specific application footprint.

What Are Typical Specs for High-Power UV LED Curing Systems?

High-power systems almost always demand liquid cooling to stay within safe operating limits. Review the specs for high-power systems to see where the cooling transition point typically lies.

Final Thoughts

Finalizing your decision on a cooling method is a step toward securing your process stability for years to come. While air cooling remains the standard for flexibility and ease of integration, water-cooled systems are increasingly becoming the foundation for high-speed, 24/7 manufacturing lines where output drift is not an option. By focusing on the thermal requirements of your specific materials and the environmental stressors of your factory floor, you can select a system that delivers consistent energy without adding unnecessary maintenance burdens. The best system is the one that stays within its optimal thermal window, regardless of how demanding your production cycle becomes.