Best UV LED Curing System for Flexo Label Printing

The best UV LED curing system for flexo label printing is one that combines high peak irradiance (typically 12–20 W/cm²) with efficient thermal management to handle heat-sensitive substrates without distortion. Unlike traditional mercury lamps, the ideal LED system offers instant on/off capabilities, uniform UV output across the entire web width, and a lifespan exceeding 20,000 hours. For label converters, the "best" choice is specifically a system that allows for modular retrofitting, ensuring compatibility with existing presses while reducing energy consumption by up to 70%.

What Defines the Best UV LED System for Flexo?

Choosing the right curing technology is critical for label quality. While there are many options on the market, the top-tier systems share specific characteristics that directly impact your bottom line and print quality.

High Peak Irradiance and Dose

For flexographic printing, especially when running at high speeds, you need a system that delivers consistent energy density. The best systems provide high peak irradiance to ensure the ink penetrates and cures all the way through to the substrate—critical for achieving good adhesion on non-porous materials like films and foils.

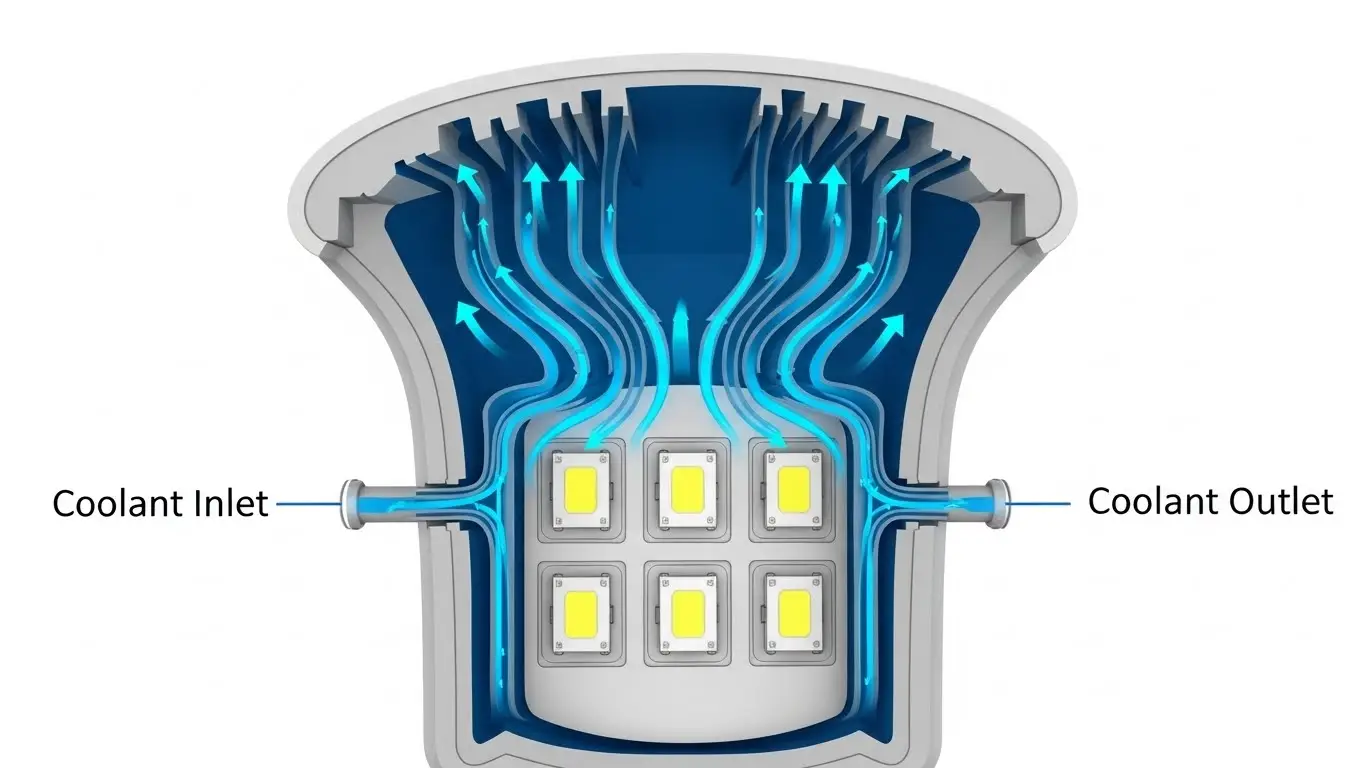

Thermal Management Efficiency

One of the primary reasons converters switch to UV LED curing for flexo & labels is the ability to print on heat-sensitive materials. A superior system uses advanced water or air cooling to keep the LED array at a stable operating temperature. This stability prevents the "thermal drop-off" that can lead to uncured ink in the middle of a long production run.

Why Are Converters Switching from Mercury to LED?

The shift from conventional mercury arc lamps to LED is driven by efficiency and substrate versatility.

Energy Efficiency and Cost Savings

Traditional mercury lamps run hot and waste significant energy producing infrared heat. In contrast, UV LED systems consume significantly less power because they only emit the specific wavelength needed for curing (usually 395nm or 385nm). They also turn off instantly between jobs, eliminating the warm-up and cool-down cycles that waste electricity.

Expanded Substrate Capabilities

Because LED systems emit negligible heat toward the substrate, converters can expand their product offerings. You can confidently run thin unsupported films, shrink sleeves, and thermal labels without worrying about the web warping or distorting.

For a deeper dive into the technical differences, it is helpful to understand exactly what is LED UV curing in flexo printing compared to older methods.

Does UV LED Curing Work for All Label Applications?

Yes, but it requires compatible ink formulations.

While UV LED hardware is robust, the chemistry is equally important. The "best" system is only as good as the ink it cures. Most major ink manufacturers now offer dual-cure or LED-specific inks designed to react to the narrow 395nm wavelength.

However, for food packaging labels, you must ensure your system provides a "full cure" to prevent migration. High-performance LED systems are excellent for this because their output doesn't degrade over time like mercury bulbs, ensuring the cure quality on day 500 is the same as day 1.

How Do UV LED Systems Improve Press Uptime?

They eliminate bulb replacements and maintenance downtime.

A standard mercury bulb might last 1,000 to 2,000 hours before its output drops significantly. A UV LED system typically lasts over 20,000 hours. This means you aren't stopping the press every few weeks to change dangerous, mercury-filled bulbs. The consistency of LED means operators spend less time troubleshooting cure issues and more time printing sellable labels.

Comparison: Mercury Arc vs. UV LED for Labels

| Feature | Traditional Mercury Arc | UV LED Curing System |

| Heat Output | High (High IR content) | Low (Negligible heat transfer) |

| Warm-up Time | Slow (Minutes) | Instant (Milliseconds) |

| Bulb Lifespan | ~1,500 Hours | >20,000 Hours |

| Energy Use | High | Low (50-80% savings) |

| Ozone Generation | Yes (Requires extraction) | No |

Frequently Asked Questions

What is the ROI on a UV LED curing system?

While the initial investment is higher than mercury systems, the ROI is typically achieved within 12 to 24 months through energy savings, elimination of bulb replacement costs, and increased press uptime.

Can I retrofit my existing flexo press with UV LED?

Yes. Most modern UV LED systems are designed with modular form factors specifically for retrofitting. They can often slot into the same space as your existing cassettes.

Is UV LED curing safe for food labels?

Yes, provided you use low-migration LED inks and ensure the system is calibrated to deliver the correct dose. The consistency of LED actually makes it safer for process control than degrading mercury bulbs.

Do I need to change my anilox rolls for UV LED?

Generally, no. You can usually use your existing anilox inventory. However, because LED inks can have different viscosities or pigment loads, minor adjustments to cell volume might be optimized later for best results.

What wavelength is best for flexo label printing?

The industry standard for flexo label curing is 395nm. This wavelength offers the best balance of depth of cure (penetration) and surface cure for the thickness of ink layers typically used in label printing.

Key Takeaways

- Heat Management: The best systems allow you to print on thin, heat-sensitive films without distortion.

- Consistency: LED offers uniform output for 20,000+ hours, eliminating the variability of mercury bulbs.

- Energy Savings: Expect to reduce curing energy costs by up to 70% due to instant on/off capabilities.

- Ink Compatibility: Ensure you pair your hardware with LED-optimized or dual-cure inks for successful results.

Conclusion

Finding the best UV LED curing system for flexo labels is about balancing power, reliability, and integration. By switching to a high-quality LED solution, you future-proof your press room, lower your environmental footprint, and open the door to profitable new applications like shrink sleeves.

If you are ready to upgrade your label printing capabilities, contact us today to discuss the ideal UV LED configuration for your specific press.