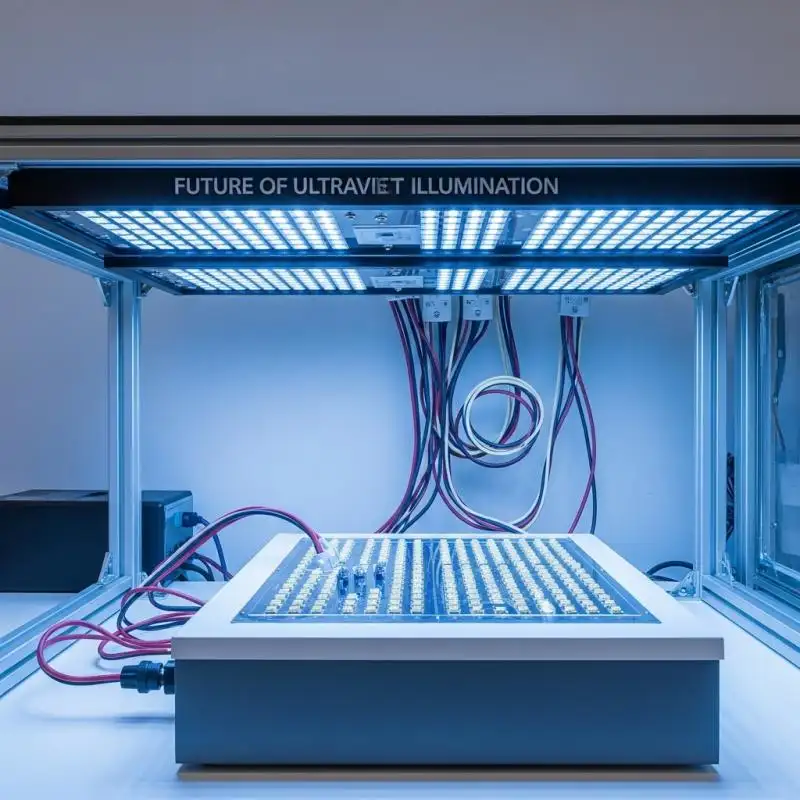

How Does UV LED Spot Curing Work? A Complete Beginner’s Guide

What is UV LED Spot Curing Work?

“Curing, manufacturing, and finishing” are three activities that must occur in today’s technology industries with high precision and accuracy. Missed deadlines are not an option, and this has led to advancements in curing techniques such as UV LED spot curing, which relies on curing adhesives, paints, and inks energy efficiently, and at a rapid pace. What makes this technology promising and gaining interest across various industries? That’s exactly what we will cover in this overview: the science, the benefits, the applications, and the future.

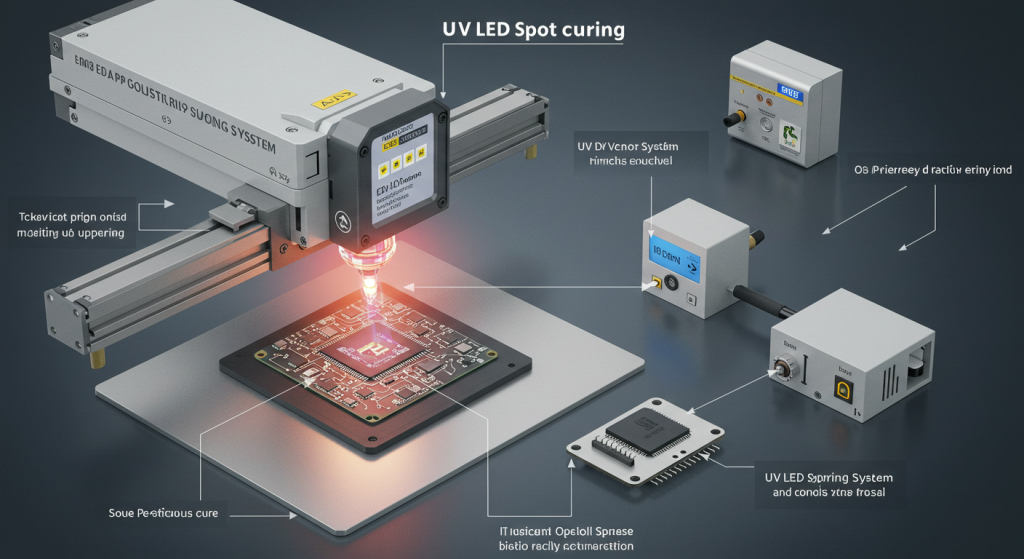

How a UV Does LED Spot Curing Work?

How does UV LED spot curing work? Under the category of UV LED spot curing lies the process of curing inks, coatings, and adhesives with corresponding light sources. UV LED operators accomplish this by aiming lasers at dots of adhesives and shocking them with lasers that have specific wavelengths (365nm, 385nm, or 405nm). Unlike the old methods with mercury lamps, these new models have their advantage as they emit light at precise wavelengths. Other UVC “LED” methods produce superior results than earlier mercury-sustaining light bulb types.

- The chemical changes involve a step of curing that relies on UV light. When these rays touch the surface, they activate certain parts called photoinitiators inside the particular material, and a reaction known as polymerization occurs. Due to radical rearrangement, a lapse of time will lead to photoinitiators transforming the liquid adhesive into a solid, strong bond.

- Its high precision makes it suitable for sanitary processes such as medical device bonding, microelectronics, and optical assembly.

- The low emission of heat, energy consumption, and increased lifespan of UV LED spot curing systems are very advantageous. They provide faster curing as well as lower maintenance compared to traditional UV lamps. Additionally, they are more environmentally friendly since they do not contain mercury or produce ozone.

- This technology finds application in high-precision medical devices where limbs are catheterized and assembled PCBs, because these industries strive for speed and material compatibility. Ultra-reliable and accurate solutions are required in modern manufacturing, which is precisely what the UV LED spot-curbing system delivers.

Advantages of UV LED Spot Curing

1. Energy Efficiency

The comparison of UV LED systems with mercury vapor lamps reveals a striking difference in energy consumption. The power expense and cost of operating the system are lowered due to the more efficient conversion of electrical energy to UV light and its subsequent expenditure. Moreover, the possibility to instantly turn UV LEDs on and off eliminates the warm-up time required by traditional lamps and further enhances productivity.

2. Environmental Benefits

The absence of toxic elements such as mercury or the generation of ozone during the use of UV LEDs greatly improves workplace health and safety by rendering harmful pollutants obsolete. Special disposal methods are not needed, thus lowering costs.

3. Precision and Control

UV LED spot curing units focus specific stunning amounts of energy at particular locations so that certain areas, even the most difficult regions to reach, can be cured uniformly. This approach is highly effective when ensuring the finishes on high-quality surfaces are attained while minimizing wastage 4. Expanding Volume and Life Care.

Applications of UV LED Spot Curing

1. Medical Device Assembly

Ultraviolet LEDs are used as bonds for components in a medical device. Due to the low heat generated by a UV output, bond accuracy alongside the safeguarding of sensitive parts is assured.

2. Electronics Manufacturing

In terms of optics, UV LED ensures the bonding of components or optical fibers with electronics. This application is best suited for UV LED devices due to the rapid curing speed and low heat associated with it.

3. Automotive Industry

Bonding and sealing in the automotive industry make use of UV LED curing. This technology enables the creation of tough, precise components of superior quality, helping it become a standard in the industry.

4.3D Printing

UV LED curing is a core process in SLA and DLP 3D printing. The ability to cure resin, layer by layer, with such pinpoint accuracy, improves the complexity and detail attainable in the finished 3D printed objects.

Safety Considerations

Despite the reduction of risks associated when using UV LEDs over UV lamps, the following steps should be taken for maximum safety:

• Eye Protection: Radiation Eye guarding is required as staring directly at the radiation poses a threat. Users need to wear proper protective goggles.

• Skin Protection: Radiation hurts the boundless layers of skin, and prolonged exposure may lead to dangerous burns. Proper clothing, like overalls or gloves, should be and is recommended when using UV LED curing systems.

• Ventilation: It is advisable to avoid ozone or other residual substances that may be created during the curing cycle; hence, the need for fresh air in the workspace.

Selection of the Correct UV LED Spot Curing System

How does UV LED spot curing work? Quite often, the environment, materials, and application processes are clear indicators of the most appropriate UV LED spot-curing system. Understanding the operation of the UV LED spot curing technique requires knowledge of the basic parts and their interrelations to the curing surface. UV adhesive bonding, the micro-assembly of PCBs, catheter bonding, optical lens fixing, and even miniature watchmaking have developed specialized curing solution requirements. To start, check the area and the material parameters for the system configuration:

• Light guides should be narrow and focused for 1 to 3 mm micro-bonding inserts (catheters, sensors)

• For primary operations in precision assembly, 3 – 10 mm spots are adequate.

• Most efficiently serviced are numerous curing points by systems with multiple outputs or split-light.

Next, think about the LEDs’ wavelengths. Certain ranges of light work better for particular types of adhesives.

• Layers of thick opaque pieces are best cured with 365nm rays.

• General coatings and adhesives are best cured with 385nm/395nm rays.

• Clear or thin-layered resins are best cured with 405nm rays, as they allow for rapid surface curing.

While evaluating the performance of a UV lamp, consider the following concerning the UV curing intensity:

- For delicate bonds, a low intensity of approximately 1000 mW/cm² is preferable.

- At higher intensities, over 2000 mW/cm², curing can be performed rapidly at high throughput rates.

Conclusion

Short light guides of higher grades better deliver a constant output of UV throughout the entire light guide. Review the thermal control for your system. For convenience, select units with modular expansion, PLC custom timing controls for multi-channel processes. Preventive safety procedures have to be prioritized first. Focus on UV protection, ergonomic features, protective CE marks like RoHS, ISO certs, and especially if it is a cleanroom medical design. Visit UVET for more information.