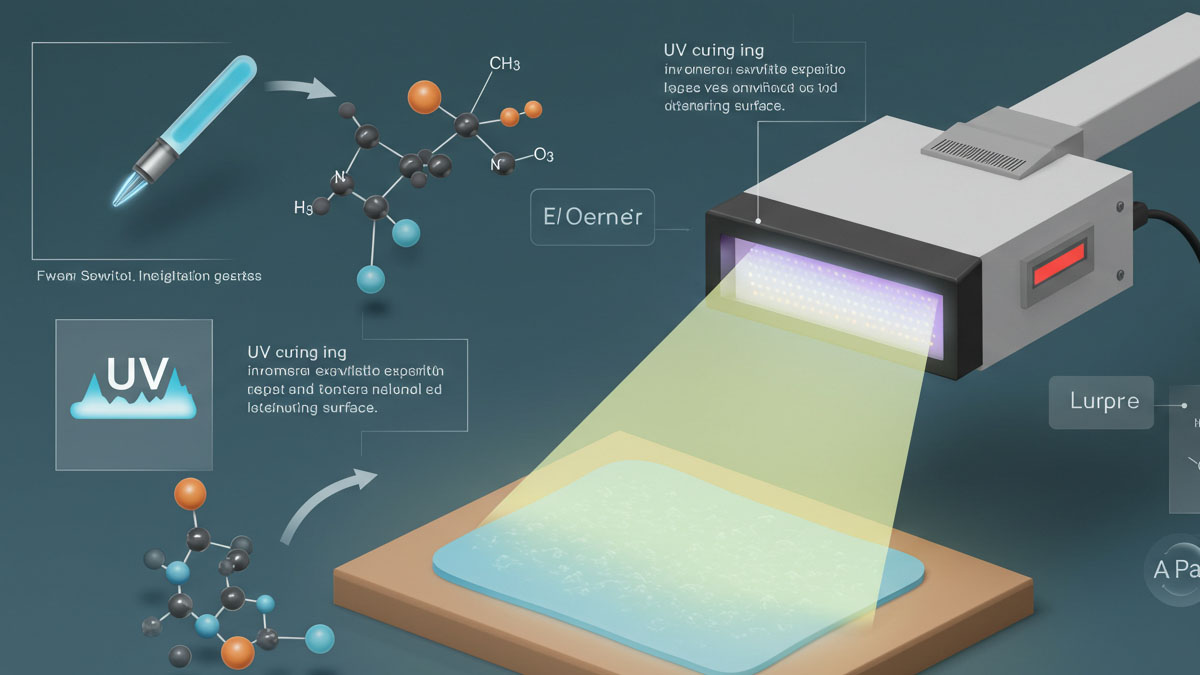

Handheld LED UV Curing Lamp

Instant Cure, Precise Beam — Professional UV Curing Power

Industrial-grade portable ultraviolet curing equipment for precise and quick curing processes is known as the Handheld LED UV Curing Lamp. The curing lamp's LEDs are economical, provide a strong radiation source, and emit very little heat, thus making them suitable for curing UV adhesives and inks.

Key Features of Our Handheld LED UV Curing

-

Cool Light Source

-

Multiple Wavelength Options:365nm, 385nm, 395nm,

-

LED life exceeds 20,000 hours

-

Instant Start

-

Approx. Ø10–50mm

-

3W–10W

Let us partner with you to create solutions that drive innovation, efficiency and success in your industry!

Applications:

-

Bonding and encapsulation of electronic components

-

Curing of adhesives with UV light in medical appliances

-

Assembling optical lenses

-

Adhesive applications in automotive lighting systems

-

Labeling and surface finishing

-

Rapid bonding and curing in jewelry and craft items

How to Choose the Right Handheld LED UV Curing

1. Different Materials Matched to Their Appropriate UV Wavelengths

Different materials will respond to specific wavelengths:

-

365nm – Full penetration for thicker coatings and UV adhesives

-

385nm/395nm – General-purpose UV resins, inks, and coatings work well with these

-

405nm – Best for Quick surface curing, usually with certain 3D printed resins

Always refer to the adhesive or resin’s technical data sheet to verify the correct wavelength.

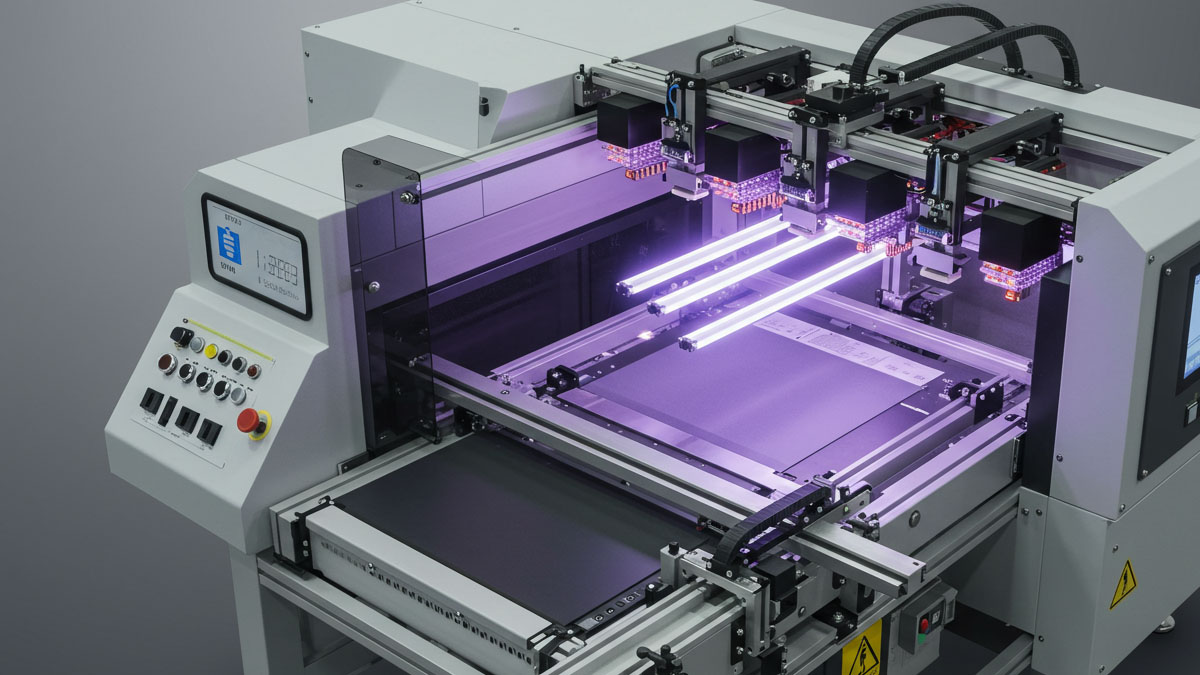

2. Check The Power And Intensity Of Curing

Changing the power settings yields different results in curing time (measured in cm2, watts, or mW/cm2).

-

Lower power (< 5W) – Small area applications

-

Higher power (5W – 10W+) – Thicker materials, faster Industrial use.

Seek models with adjustable power and built in intensity control for diverse material applications.

3. Analyze the Spot Size and Beam Uniformity

-

Small, ~10mm, spot size—specially advantageous for tasks which require high precision, for example, electronics or medical devices.

-

Larger, 20-50mm, spots are more suitable for bonding or coating over larger areas.

-

For uniform energy output, the beam must be uniform; otherwise, inconsistency will result in over or under curing at the edges.