LED UV Curing Systems – Reliable, Fast, and Energy-Efficient

Advanced UV LED curing solutions for high-precision industrial applications

LED UV Curing Systems have pronounced implications for industrial processes due to their speed, precision, and environmental friendliness. Compared to traditional UV lamps, LED UV curing systems have instant on/off capability, a longer operational lifespan, and use up to 50% less energy. In addition, our products offer spot and area curing solutions as well as chamber based curing with guaranteed reliability and optimal performance for curing requirements.

-

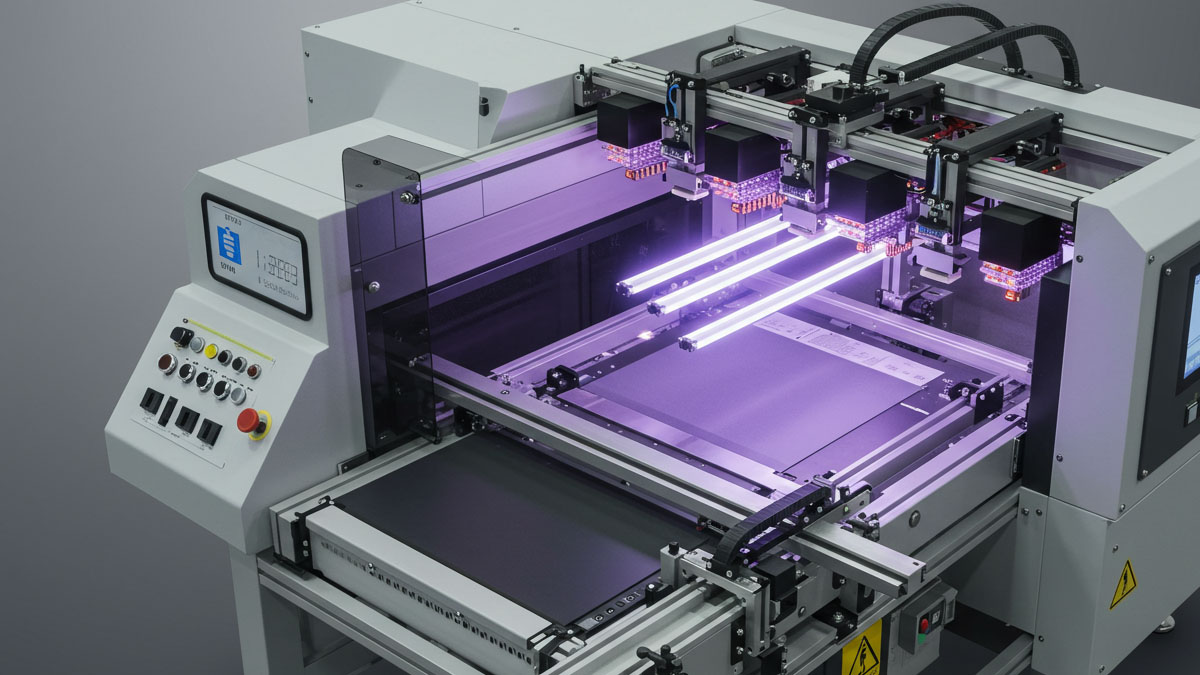

LED UV Curing Lamp for Screen Printing

LED UV Curing Lamp for Screen Printing- Irradiation Area: 500x20mm

- Intensity: 12W/c㎡ @365nm

- 16W/c㎡ @385/395/405nm

Learn More -

UV LED System for Printing

UV LED System for Printing- Irradiation Area: 650x20mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More -

UV LED Lamp for Printing

UV LED Lamp for Printing- Irradiation Area: 700x10mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More -

UV LED for Ink Curing

UV LED for Ink Curing- Irradiation Area: 1500x10mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More

Key Features of our LED UV Curing

-

Instant Curing

-

Longer Lifespan

-

Energy Efficient

-

Eco-Friendly, no ozone emissions

-

Consistent Performance

-

Multiple wavelengths, intensities and configurations

Let us partner with you to create solutions that drive innovation, efficiency and success in your industry!

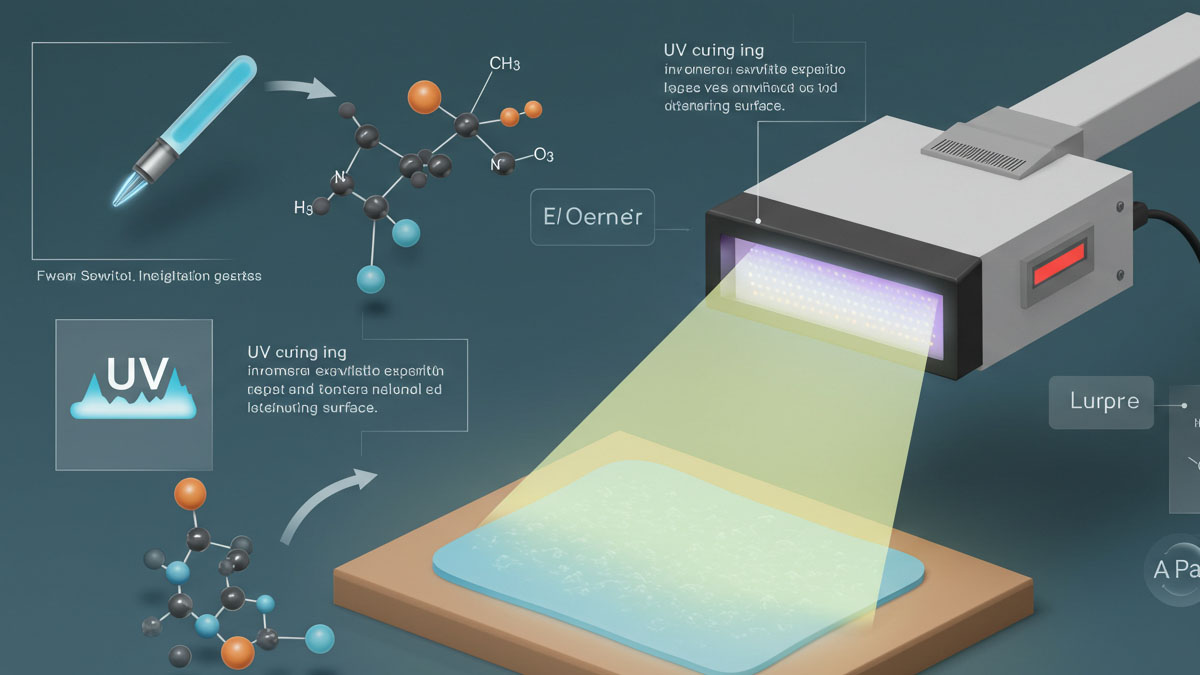

Understanding LED UV Curing Technology

LED UV curing is a process that relies on powerful ultraviolet light to instantly cure adhesives, coatings, and inks. Compared to conventional UV lamps, LED UV curing systems have lower heat output, making them more suitable for heat-sensitive materials such as plastics and electronic parts.

Key Benefits of LED UV Curing:

- There are no need for cooling systems because of very low heat emission.

- Offers microelectronics and medical devices precise curing.

- Reduced production downtime because of instant on/off function.

How to Select the Best-Fitting LED UV Curing System?

Q1: What is the difference between UV LED spot and area curing?

A: Spot curing works best for small component bonding or other localized operations while area curing is applicable to large surface treatments.

Q2: Is LED UV curing technology safer compared to other forms?

A: Yes! With no ozone or mercury emissions, UV LED systems are far more advantageous to the users and the surrounding environment.

Q3: Are there any opportunities to use guaranteed LED UV for fast printing processes?

A: Certainly. Our systems for printing are equipped with UV LED's which guarantee immediate curing, further improving the strength of prints.

How to Choose the Most Fitting LED UV Curing Solutions for Your Applications?

- For electronics and PCB fabrication lines: UV LED spot curing is the most ideal.

- For extensive industrial coating: UV LED area curing or chamber systems are better suited.

- For fast printing: Custom-engineered UV LED printing units offer specialty features for fast-paced printing.

For precise and productive processing with minimal waste of resources, our systems are tailored to meet the requirements of great accuracy and energy efficiency. If you would like expert help with system design, other tailored options are available through our specialists as well.

(1).png)