Bright Ideas in Every Layer

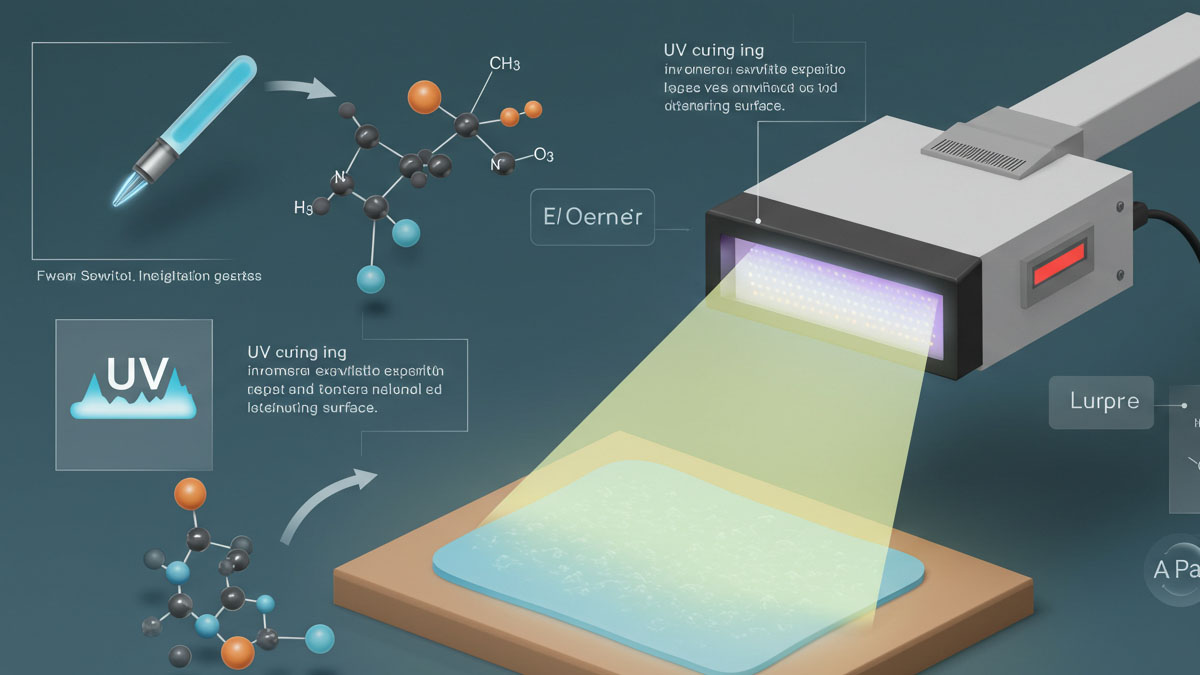

Enhance print durability and visual impact with a curing system designed for brilliance. Uniform UV exposure ensures long-lasting, smudge-free results on every print job.

The UV LED Curing Systems for Printing is tailored specifically for digital inkjet, screen, flexo, and even offset printing. It modern UV LED technologies to instantly cure UV inks and varnishes. This also improves the print’s quality, speed of production and the materials used.

This system can provide multiple wavelengths of UV light such as 385nm, 395nm or 405nm, making it suitable for adhesives and coatings on a wider range of materials which include paper, plastic, film, foil and metal. Due to the modular features of the system, it can be easily integrated into new or fully functional presses without hindering their operations. It can be used in high speed applications as long as consistent UV light intensity is provided with minute thermal energy.

-

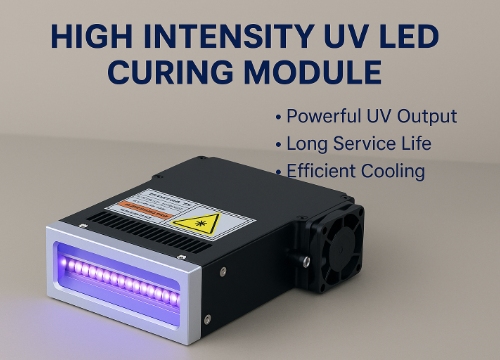

UV LED System for Printing

UV LED System for Printing- Irradiation Area: 650x20mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More -

UV LED Lamp for Printing

UV LED Lamp for Printing- Irradiation Area: 700x10mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More -

UV LED for Ink Curing

UV LED for Ink Curing- Irradiation Area: 1500x10mm

- Intensity: 8W/c㎡ @365nm

- 12W/c㎡ @385/395/405nm

Learn More

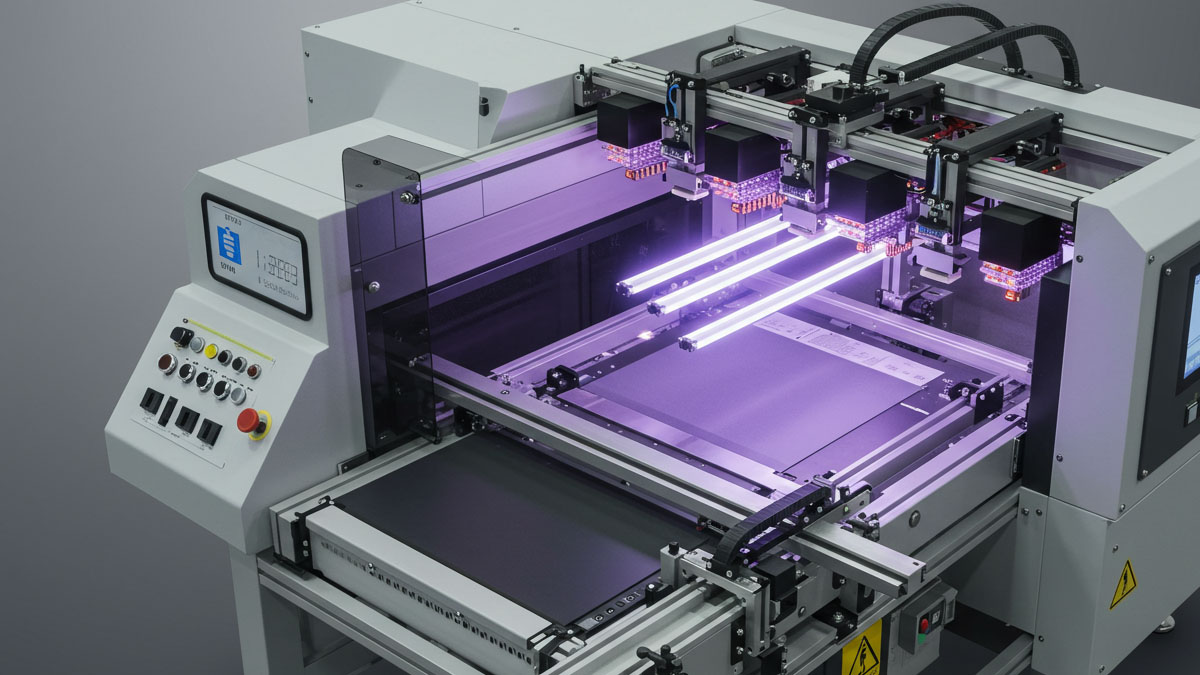

Typical Applications of our LED UV Curing

-

UV inkjet printing

-

Flexographic and offset printing

-

Label and packaging production

-

Varnish coating and surface finishing

-

Plastic card or film printing

-

Metal and foil substrate decoration

Partner with us to advance your printing operations through cutting-edge UV LED curing systems that deliver efficiency, consistency, and precision

Supports Accelerated Manufacturing Through Instant Curing

Productivity is further enhanced as higher speeds, as well as continuous and high-speed printing are enabled by instant drying of ink through UV LED technology.

Low Radiation Does Not Damage Thermally Sensitive Materials

Thermally low emission radiation is appropriate for films, labels, plastic sheets, and other substrates as it causes no overheating and distortion.

Also suitable for paper, PVC, PET, foils, aluminum and metal.

Reduced Energy Consumption, Environmentally Friendly

Does not contain mercury and emits no ozone, resulting in over 50% energy savings compared to older styles of mercury lamps.

Due to the over 20,000 hour lifespan of LED lamps, operating and maintenance expenses are lower.

For Modular Configurations Integrated Printer Systems Are Suitable

Remotely controlled inkjet, flexographic or even offset presses can be modified to be mounted with compact and scalable modules, perfect for retrofitting or upgrading.

How to Choose the Right UV LED Curing Systems for Printing

Picking the most suitable system for printing is important because of quality output, efficiency of workflow, and organizational structures. To achieve the selection of utmost importance undertaking the processes below will help:

Identify Your Technology Printing

Every method of printing comes with a unique set of needs with regard to the configuration of the curing system:

- Inkjet printing – Compact and precise UV modules for inkjet printing must have an instant on/off control.

- Flexographic – Stamping requires robust and fast curing across wide areas for substrates.

- Offset printing - Requires fast-acting systems for hybrid UV varnishes or inks.

Always ensure to match your press type and ink actions systems.

Align Your Curing Ink with The Wavelengths

Commonly used UV LED wavelengths are:

- 365nm – Deep curing for specialty inks and adhesives.

- 385nm / 395nm – General purpose UV inks.

- 405nm – Certain digital inks benefit from quicker surface curing.

For proper performance and adhesion verification, coordinate with your ink supplier.

Adjust UV Light Pickup Speed for Printing and Curing Efforts

An increase in print speed equates to an increase in required UV intensity (mW/cm²).

- Low-speed printers draw between 1000 and 2000 mW/cm² power.

- High-speed presses: Look for systems that exceed 3,000 mW/cm².

Make sure your maximum line speed does not result in under-curing.

Ensure Proper Cooling System

Based on power output requirements:

- Air-cooled systems: More advantageous for low-powered, compact systems.

- Water-cooled systems: Critical for high-powered, constantly running industrial systems.

Cooling substantially affects uniformity and consistency of performance as well as lifetime of LEDs.

Size and Mounting Compatibility

Choose a module size that:

- Fitted to your print width (e.g. 100mm, 300mm, 600mm etc).

- Can be easily mounted or retrofitted to existing structures.

Modular designs are best when constraints are sequentially scaling up, or replacing only parts of a line.

Control and Integration Features

Look for systems with:

- External I/O control (to sync with printers or PLCs).

- Power and timers with adjustable values.

- Status or intelligent diagnostics indicators.

Effective integration enhances automation, minimizes operator error.

Safety and Certifications

Check that the system has:

- shielding and interlocks.

- CE, ROHS or other relevant certifications.

- Documented terms for warranty and support that is dependable.

| Factor | What to Look For |

|---|---|

| Printing method | Inkjet, flexo, offset compatibility |

| Wavelength | Matches ink type (365 / 385 / 395 / 405 nm) |

| UV intensity | Sufficient for your print speed |

| Cooling system | Air or water cooled based on duty cycle |

| System size | Covers print width, fits machine frame |

| Integration options | External trigger, PLC, adjustable settings |

| Safety & support | Certifications, UV shielding, tech support |

(1).png)