UV LED Spot Curing -Small Spot. Big Impact

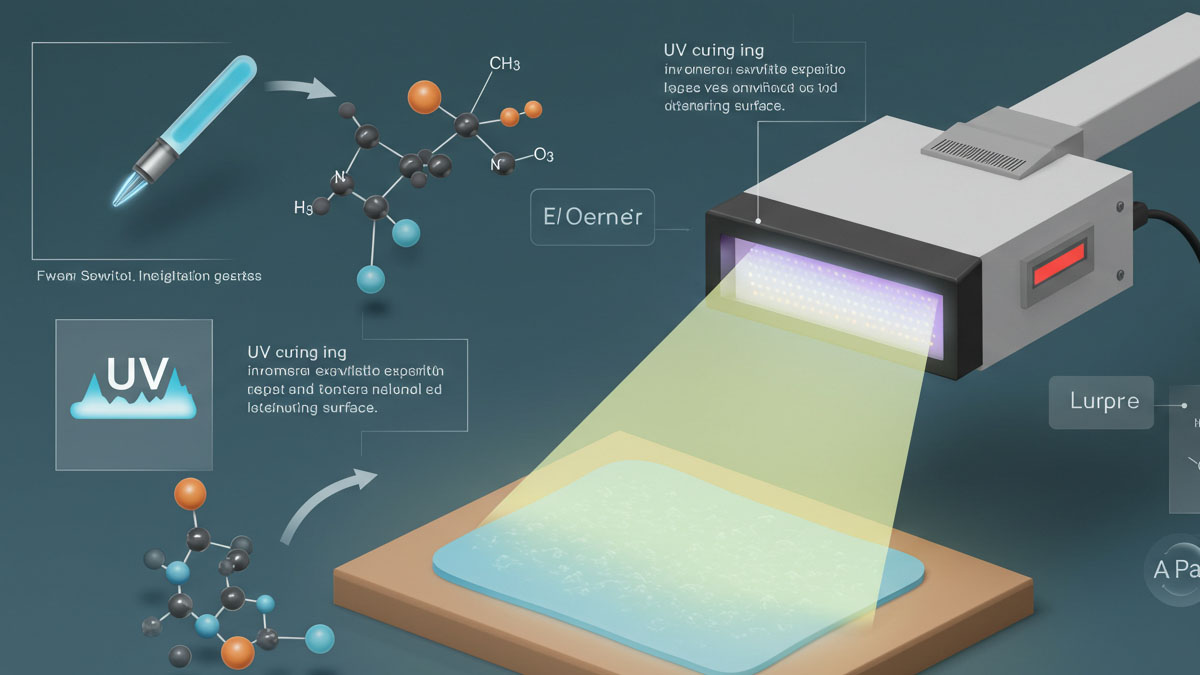

Achieve exact curing with high-powered UV LED output, engineered for applications requiring fine detail, minimal heat, and rapid cycle times.

The UV LED Spot Curing System is a sophisticated light-curing system that delivers elevated precision and control during the photo-initiated polymer curing process. It is useful for applications demanding rapid curing such as: micro-components assembly, bonding of medical devices, and assembly of optical parts.

The system also addresses all the primary needs of the industry micro-manipulators such as UV high power LED, instantaneous ON/OFF switching, reduced radiant energy output at lens fibers, and heating of focus lens mounts. It can be set to function automatically or manually, and features fiber-optics with endless tubing diameters.

-

UV LED Spot Curing System

UV LED Spot Curing System- UV Spot Size: Φ3~Φ15mm

- Wavelength: 365/385/395/405nm

- Intensity: up to 14W/cm2

Learn More -

UV LED Curing Device

UV LED Curing Device- Water Cooling

- Irradiation Area: Φ25~Φ50mm

- Intensity: 1500mW/c㎡ @365nm

- 2000mW/c㎡ @385/395/405nm

Learn More -

UV LED Curing Pen

UV LED Curing Pen- UV Spot Size: Φ4~Φ15mm

- Wavelength: 365/385/395/405nm

- Intensity: up to 14W/cm2

Learn More

Typical Applications of our UV LED Spot Curing

-

Precision UV adhesive bonding

-

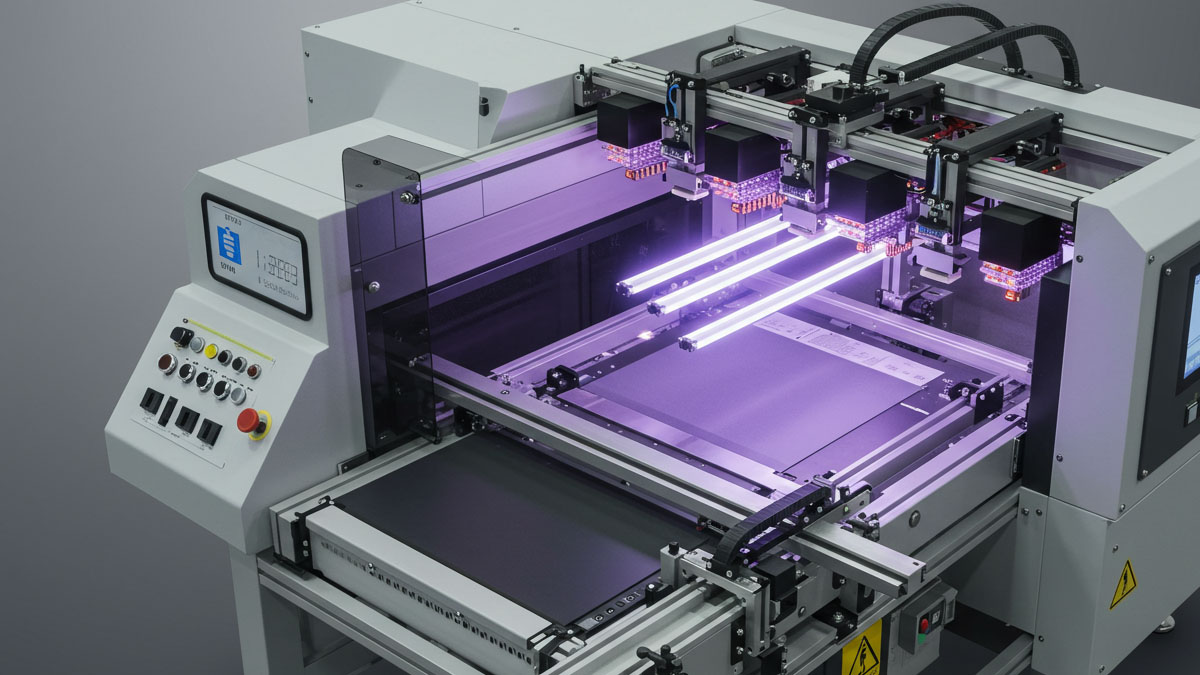

PCB and microelectronic component assembly

-

Catheter and medical tube bonding

-

Optical lens alignment and fixing

-

Watchmaking, jewelry, and miniature part assembly

Partner with us to deliver UV LED Spot Curing solutions that boost innovation, enhance efficiency, and drive success in your industry!

1. Subsystems

Power controller of the UV LEDs

- Output intensity, wavelength selection, and operation modes for outputs are controlled by the power controller for UV LEDs.

- Typically includes a timer, digital display, and a multifaceted port output within the device.

Light Guide (Fiber or Liquid Light Guide)

- Delivers UV curing light accurately and diplomatically to the designated spot.

- Comes in numerous lengths and diameters as well as single and multi-head configurations.

UV LED Light Head Module

- Contains high-powered LED chip that output UV light of particular wavelength.

- Stable and consistent output is achieved by efficient coupling of light guides.

Control Options

- External and foot pedal control as well as preset buttons are supported.

Optional Accessories

- Holds for goggle-type shields, under goggle heatsinks, and standard protective covers which block foreign UV light.

Power controller of the UV LEDs

- Output intensity, wavelength selection, and operation modes for outputs are controlled by the power controller for UV LEDs.

- Typically includes a timer, digital display, and a multifaceted port output within the device.

Light Guide (Fiber or Liquid Light Guide)

- Delivers UV curing light accurately and diplomatically to the designated spot.

- Comes in numerous lengths and diameters as well as single and multi-head configurations.

UV LED Light Head Module

- Contains high-powered LED chip that output UV light of particular wavelength.

- Stable and consistent output is achieved by efficient coupling of light guides.

Control Options

- External and foot pedal control as well as preset buttons are supported.

Optional Accessories

- Holds for goggle-type shields, under goggle heatsinks, and standard protective covers which block foreign UV light.

How to Choose the Right UV LED Spot Curing

-

Identifying your application and working area for curing.

Tailor the design to the kind of material and dimensions of the spot that need curing:

-

Micro-bonding (e.g., sensors, catheters) → Requires miniaturized light guiding tubes of 1-3 mm in diameter.

-

General precision assembly → Requires medium spot size of 3-10 mm.

-

Multiple curing points → Need multi-head output and/or light splitting systems.

Configure system to your specified spot size, depth of cure, as well as geometry of the part.

-

-

Different types of UV-curable materials are best responsive to certain ranges:

-

365nm – For deeper penetration, best suited for thick adhesives or opaque substrates

-

385nm / 395nm – Widely used with general-purpose UV adhesives and coatings

-

405nm – Used for quicker surface curing, usually paired with clear or thin-layer resins

Always adhere to the technical datasheet of the adhesive/resin used for the corresponding wavelength.

-

-

Select The Right Type of Light Guide

-

Liquid and fiber light guides differ in rigidity, flexibility, and how well they transmit light.

-

Choose the diameter and length appropriate to your setup (robotic limbs, tight spots).

-

Some systems allow modification with different light guides providing adaptability.

-

Short high-quality light guides are always preferred as they have consistent output.

-

-

Looking At Curing Intensity And Time

-

Check whether the system being used has the capability to supply enough UV power (mW/cm²);

-

Low-intensity systems for sensitive, low-viscosity adhesives (around 1000 mW/cm²)

-

High-intensity systems (2000+ mW/cm²) meant for rapid curing or high throughput applications.

-

-

Look for Control and Integration Features

-

For optimal operation and automation:

-

Footswitch or timer for manual operations

-

PLC or external trigger for automated production lines

-

Multi-channel controllers for simultaneous curing at different locations

-

-

Follow your workflow: benchtop, semi-automatic, inline system, or others.

-

-

Look for Thermal Management

-

Passive cooling is adequate for intermittent-work users

-

Active cooling is required for continuously high-power applications (fans or heat sinks)

-

Appropriate cooling improves LED lifespan while stabilizing curing performance.

-

-

Safety and Ergonomics

-

Check for shielding accessories like glasses or covered shrouds to block UV radiation

-

Look at the small and ergonomic overall appearance for operator comfort.

-

Check compliance (CE, RoHS, ISO) for use in lab or cleanroom setting.

-

✔️ Summary Checklist:

| Factor | What to Look For |

|---|---|

| Application | Micro-bonding, general assembly, multi-point use |

| Wavelength | 365 / 385 / 395 / 405 nm |

| Spot size | 1–10 mm, customizable via light guide |

| UV intensity | Based on adhesive and curing speed needed |

| Light guide type | Fiber vs. liquid, length and diameter |

| Control options | Manual, timer, PLC, multi-channel |

| Cooling system | Passive or active based on usage intensity |

| Safety & compliance | Shielding, certifications, cleanroom compatibility |