UV Tape Curing Systems - Perfect Cure. Reliable Bond

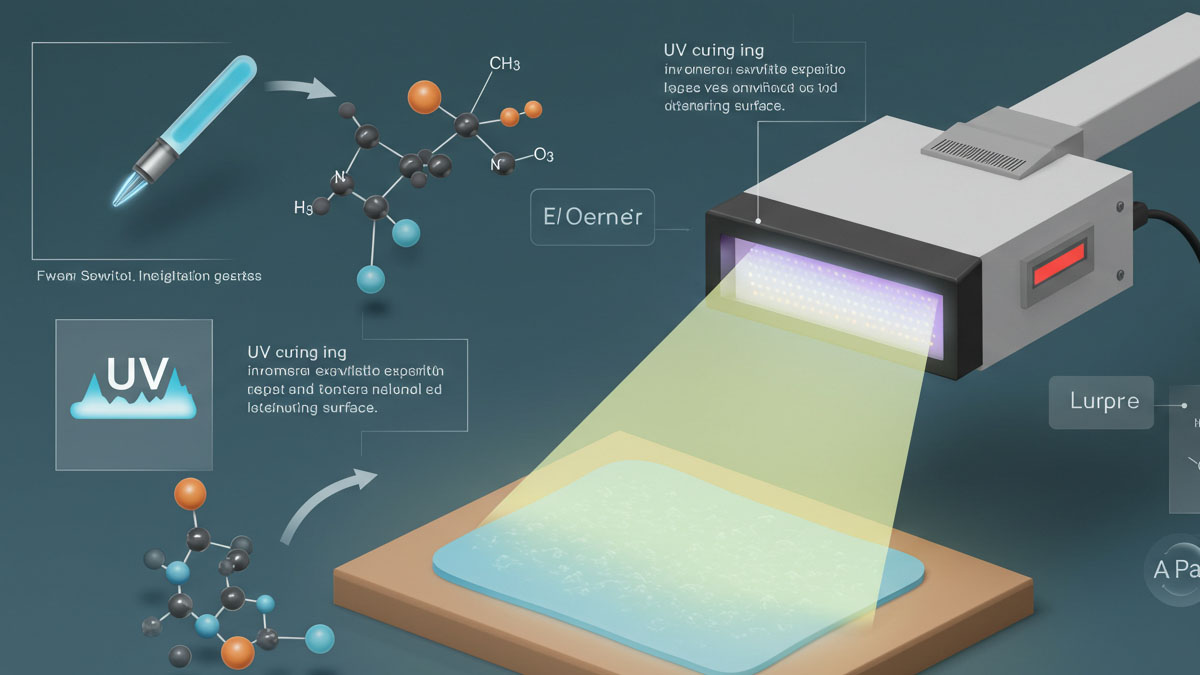

Designed for UV-sensitive adhesives, our systems offer fast, uniform curing for tapes used in micro-assembly, die bonding, and wafer processing—improving bond strength and process reliability.

UV Tape Curing Systems demonstrate singular concentration on tape curing, which sets it apart from the rest of such systems. It is indicative of the widespread acceptance of high-intensity UV LED. Through these, precision industries like semiconductor packaging, electronics assembly, and glass processing that demand delicate and meticulous work can benefit from risk-free heating and effective tape curing.

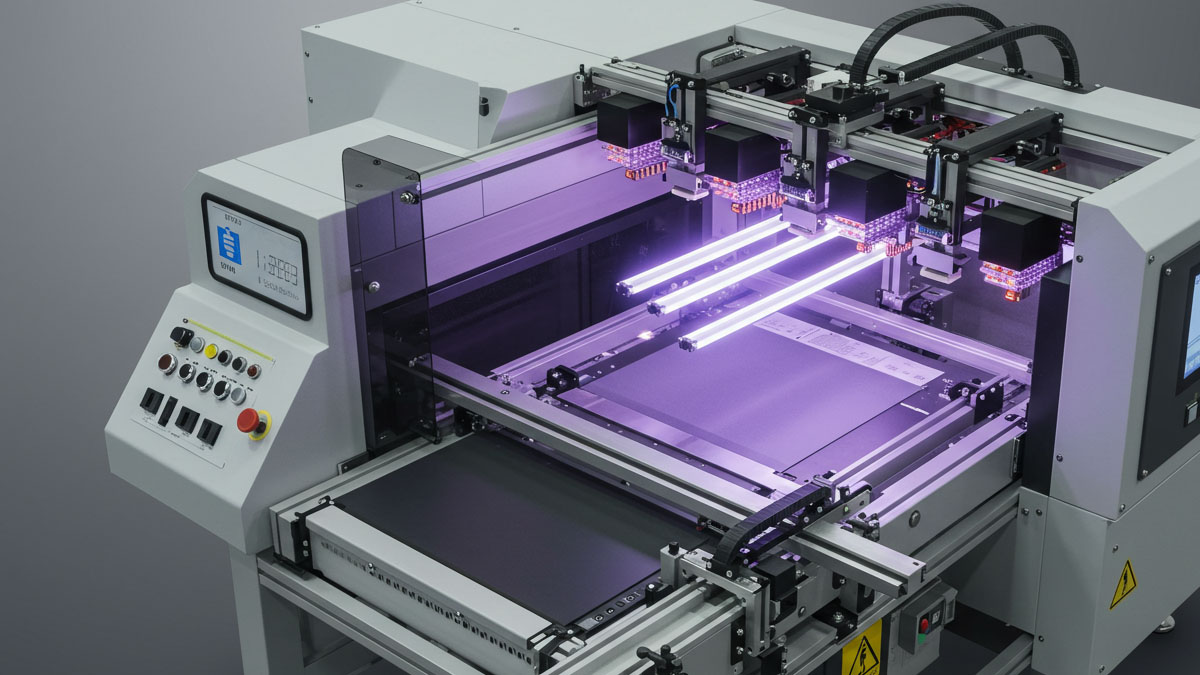

The system is also easily adjustable to an inline or bench setup designed for high throughput modes and therefore caters to a variety of applications. An instant-on feature combined with low power drain, long service hours, and stitchability to tapes makes enhancement to adhesive bond strength possible.

Application Scenarios

-

Semiconductor Manufacturing

-

Optical Component Processing

-

Electronic Packaging

Partner with us to develop cutting-edge UV Tape Curing System solutions that empower innovation, enhance efficiency, and drive success across your industry.

Key Features & Applications

- UV Tape Curing: While dicing and back grinding a wafer, exposure to UV light helps in tape bonding reduction which simplifies chip picking.

- High Adaptability: Treated UV dicing tapes are applicable to semiconductor wafers, glass, ceramics, and a number of other materials.

- Greater Process Productivity: Enhanced response speeds and improved suprachronic recovery combined with system-wide hold time reductions improve productivity.

📊 Main Technical Specifications

| Parameter | Description |

|---|---|

| Wafer Size Support | Available for 6", 8", 10", 12" wafers (customizable) |

| UV Wavelength | Standard 365 nm; optional range from 365 nm to 415 nm |

| Irradiation Method | Bottom-up exposure ensures uniform curing |

| Operation Mode | Touchscreen interface; adjustable exposure time and intensity |

| Curing Time | As fast as 5 seconds depending on tape properties |

| Light Source Type | LED cold light source; eco-friendly and long life (15,000–30,000 hrs) |

| Machine Dimensions | 459 mm × 440 mm × 286 mm (customizable) |

| Weight | Approx. 6.5 kg; compact and space-saving |

Key Advantages

- Productivity Improvement: With reduction of tape adhesion, UV LEDs used cold streaming provide high efficiency, thus improving productivity.

- Economical & Environmentally Friendly: Mercury free with no ozone emissions.

- Easy to Operate: Different stages of the process can be controlled through preset parameters on touchscreen control.

- Comprehensive Adaptability: Different sizes of wafers and tapes mounted circumferentially can be configured to other production needs.