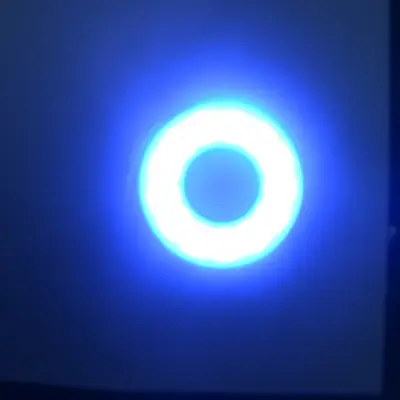

UV LED Curing Device

- Model: UVSS-13T

- Various Sizes

UVET’s UV LED curing device features a ring-type design that delivers uniform UV irradiation across a Φ25–Φ50mm coverage area. Available in three optional wavelengths—365nm, 385nm, 395nm, and 405nm—this curing device is engineered for versatility and precision. It is widely used in electronic assembly, medical device bonding, and applications in the optics and optoelectronics industries, where reliable and consistent curing performance is essential.

Specifications

| Part No. UVSS-13T | Wavelength 365nm, Intensity 1500mW/cm2 |

| Part No. UVSE-13T | Wavelength 385nm, Intensity 2000mW/cm2 |

| Part No. UVSN-13T | Wavelength 395nm, Intensity 2000mW/cm2 |

| Part No. UVSZ-13T | Wavelength 405nm, Intensity 2000mW/cm2 |

| Irradiation Area | Φ25~Φ50mm |

| Heat Dissipation | Water cooling |

-

Descriptions

The UV LED Curing Device is a compact, high-efficiency ring-type system. It delivers consistent and controlled UV light for precision curing. With an irradiation area of Φ25mm to Φ50mm and wavelength choices of 365nm, 385nm, 395nm, or 405nm, it supports a wide range of UV-sensitive materials.

This curing device is widely used in electronics, optics, and medical device assembly. It ensures clean, fast curing results with reliable performance. A water-cooled design helps maintain low operating temperatures, even during extended operation.

Features

- Targeted irradiation area (Φ25–Φ50mm): Focused UV light for efficient and accurate curing

- Multiple wavelength options (365nm, 385nm, 395nm, 405nm): Flexible compatibility with different materials

- Water-cooled thermal management: Stable output with effective heat control

- Instant on/off control: No warm-up time and reduced energy use

- User-friendly interface: Easy to operate with minimal training

- Low heat output: Protects delicate parts and materials

Advantages for Industrial Applications

The UV LED Curing Device suits a variety of precision tasks. In electronics, it’s used for bonding, sealing, and micro-assembly. These applications benefit from reliable curing and reduced heat impact.

In medical production, the system bonds parts like catheters and diagnostic housings. It works cleanly and safely with sensitive components. In optoelectronics, it helps align and secure lenses, filters, and sensors. The device ensures even UV coverage without damaging the materials.

Its beam remains stable, allowing uniform curing across complex or detailed surfaces. This consistency makes it well-suited for repeatable production processes.

What Makes This UV LED Curing Device Stand Out

Unlike traditional curing systems, this LED-driven device works instantly with no warm-up time. It produces little heat, which is safer for sensitive materials. With four wavelength choices, it adapts easily to different adhesives and coatings.

Integration is simple. It fits into benchtop stations or automated lines with minimal setup. Whether used for spot curing or detailed bonding, it offers speed, efficiency, and precision.

The UV LED Curing Device also supports energy savings and low maintenance. Its long LED lifespan and clean operation reduce downtime and running costs.

-

FAQs

Q1: What is a UV LED Curing Device used for in industrial applications?

A: A UV LED Curing Device is used to rapidly cure UV-sensitive adhesives, coatings, and inks in applications such as electronics, medical devices, automotive, and optical assembly.Q2: What are the advantages of using a UV LED Curing Device over traditional UV lamp systems?

A: It offers longer lifespan, lower heat output, energy efficiency, instant on/off control, and is mercury-free, making it safer and more reliable for production.Q3: What wavelengths are supported by the UV LED Curing Device?

A: Common supported wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm, chosen based on the specific chemistry of the UV-curable material.Q4: Can the UV LED Curing Device be integrated into automated production systems?

A: Yes, most devices support PLC connectivity, remote control interfaces, and customizable triggering options for full automation compatibility.Q5: What maintenance is required for the UV LED Curing Device?

A: Maintenance is minimal and typically involves occasional cleaning of optics and air filters, along with periodic checks of LED output for consistent performance.