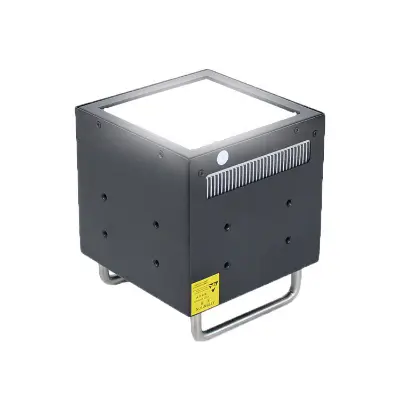

UVET’s UV LED Curing Light Source features a 100×100mm irradiation area and is equipped with fan cooling to ensure stable and efficient operation. It offers optional fixed wavelengths of 365nm, 385nm, 395nm, and 405nm, providing flexibility for various curing applications. This UV LED curing light source is widely used in electronic assembly, medical device bonding, optical component bonding, and across the optoelectronics industry, delivering consistent, high-quality UV curing for demanding industrial environments.

Home / Products / LED UV Curing / UV LED Area Curing /

Specifications

| Part No. UVSS-144A | Wavelength 365nm, Intensity 2500mW/cm2 |

| Part No. UVSE-144A | Wavelength 385nm, Intensity 3000mW/cm2 |

| Part No. UVSN-144A | Wavelength 395nm, Intensity 3000mW/cm2 |

| Part No. UVSZ-144A | Wavelength 405nm, Intensity 3000mW/cm2 |

| Irradiation Area | 100x100mm |

| Heat Dissipation | Fan cooling |

-

Descriptions

The UV LED curing light source delivers strong, uniform UV output across a wide area while maintaining stable, energy-efficient operation. Designed with a 100mm × 100mm irradiation zone, it is ideal for curing larger surfaces in high-precision production environments. With selectable wavelengths of 365nm, 385nm, 395nm, and 405nm, this system offers excellent flexibility to match various material requirements.

Its integrated fan-cooling system ensures long-term thermal stability, even under continuous operation. This makes the unit well-suited for demanding applications in electronics, medical devices, optics, and optoelectronics. Whether used for bonding, coating, or sealing, it delivers consistent results with low energy consumption and minimal heat generation.

Thanks to its compact, modular design, the system supports both standalone use and integration into larger automated setups. It adapts easily to new or existing production lines, making it a reliable and scalable UV curing solution.

Features

- Fan cooling: Keeps performance stable and prevents overheating during long-duration use

- Using the app is simple: Easy-to-navigate interface that’s accessible even to first-time users

- Flexible design: Can function on its own or within larger automated curing systems

Why Choose the UV LED Curing Light Source?

This curing system combines wide-area coverage with reliable, repeatable UV output. The 100mm × 100mm curing zone allows more surface area to be treated in each cycle, reducing production time and increasing throughput. It is especially valuable in processes such as display module assembly, circuit board bonding, and optical component curing.

With four wavelength options available, the system ensures compatibility with a wide variety of UV-reactive adhesives, coatings, and resins. This wavelength flexibility allows users to optimize curing conditions for different materials, improving bond strength and overall process quality.

The use of LED technology offers several benefits over traditional UV lamps. The light source turns on and off instantly, eliminating the need for warm-up periods. It operates at a lower temperature, reducing the risk of heat-related damage to sensitive components. In addition, it consumes significantly less energy, lowering operating costs and contributing to a more sustainable production environment.

What Distinguishes This System?

- Optimal irradiation area (100mm × 100mm): Suitable for treating large surfaces efficiently

- Many options to choose: Wavelengths of 365nm, 385nm, 395nm, and 405nm cover a broad range of applications

- LED technology advantages: Fast on/off functionality, energy efficiency, and low thermal output

- Many applications: Well-suited for electronics assembly, medical bonding, optical manufacturing, and related fields

Designed for high volume use, UV LED curing sources are a reliable solution for fast, accurate and repeatable curing.

-

FAQs

Q1: What is a UV LED Curing Light Source used for?

A: A UV LED Curing Light Source is used to initiate rapid curing of UV-sensitive adhesives, coatings, and inks in applications such as electronics manufacturing, medical device assembly, printing, and optical bonding.Q2: What are the advantages of a UV LED Curing Light Source compared to conventional UV lamps?

A: It offers lower heat emission, longer operational life, instant on/off functionality, energy efficiency, and is mercury-free, making it safer and more cost-effective.Q3: What wavelengths are available for the UV LED Curing Light Source?

A: Standard options include 365 nm, 385 nm, 395 nm, and 405 nm, with wavelength selection based on material requirements and desired curing performance.Q4: Is the UV LED Curing Light Source suitable for integration into automated systems?

A: Yes, it supports integration with industrial automation through PLC interfaces, digital I/O, and programmable controls for seamless operation in production lines.Q5: What maintenance is required for the UV LED Curing Light Source?

A: Maintenance is minimal and includes periodic cleaning of optical components, cooling system checks, and routine output monitoring to ensure curing consistency.