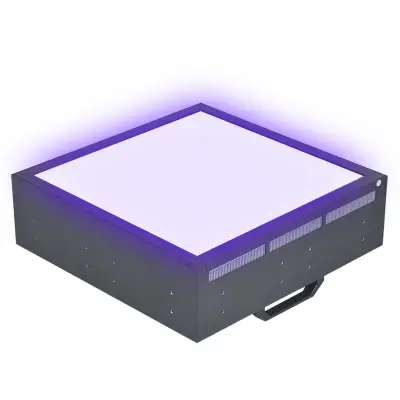

UV LED Flood Curing Panel

- Model: UVSS-784B3

- Various Sizes

UVET’s UV LED Flood Curing Panel features a large 350×350mm irradiation area, making it ideal for high-throughput curing applications. Equipped with fan cooling for stable and efficient operation, it supports optional wavelengths of 365nm, 385nm, 395nm, and 405nm to suit a variety of materials and processes. This UV LED flood curing panel is perfect for use in electronic assembly, medical device bonding, optical bonding, and the optoelectronics industry, delivering consistent, uniform curing across wide surfaces.

Specifications

| Part No. UVSS-490B3 | Wavelength 365nm, Intensity 750mW/cm2 |

| Part No. UVSE-490B3 | Wavelength 385nm, Intensity 900mW/cm2 |

| Part No. UVSN-490B3 | Wavelength 395nm, Intensity 900mW/cm2 |

| Part No. UVSZ-490B3 | Wavelength 405nm, Intensity 900mW/cm2 |

| Irradiation Area | 350x350mm |

| Heat Dissipation | Fan cooling |

-

Descriptions

The UV LED flood curing panel provides efficient and consistent UV curing across a wide 350mm × 350mm area. It is ideal for processing large components or curing several smaller parts in a single cycle. This makes it a valuable tool for industries like electronics, optics, medical device manufacturing, and optoelectronics.

The system offers four wavelength options—365nm, 385nm, 395nm, and 405nm—allowing it to match different material requirements. As a result, users can fine-tune their curing process for optimal speed and bond quality.

Thanks to its integrated fan cooling system, the panel operates continuously without overheating. This helps maintain consistent curing performance and extends the lifespan of internal components.

Features

- Proper fan cooling: Keeps internal temperatures stable and ensures reliable performance during extended operation

- Quick and easy setup: Simple controls help users start quickly with little to no training

- No need to integrate: Functions on its own or fits into automated production systems without difficulty

Why Choose the UV LED Flood Curing Panel?

This system supports large-scale curing while maintaining high precision. Its 350mm × 350mm curing zone is perfect for treating full-sized parts or multiple items arranged in batches. This reduces the number of curing passes and speeds up production.

The selectable wavelengths offer more control over how materials cure. You can match the UV output to the adhesive or coating in use. This helps improve adhesion, finish quality, and long-term durability.

The panel includes the core benefits of LED technology. It powers on instantly with no warm-up time. It also uses less electricity and produces very little heat, which helps protect sensitive components and lowers energy costs.

What Makes It Different?

- Flexible uses across industries: Supports detailed curing work in electronics, healthcare, optical bonding, and optoelectronics

- Large curing area (350mm × 350mm): Handles either large components or grouped small parts in one curing cycle

- Selectable UV wavelengths (365nm, 385nm, 395nm, 405nm): Compatible with a wide range of adhesives and coatings

- LED advantages: Fast on/off control, energy efficiency, minimal heat, and long service life for reduced maintenance

The UV LED flood curing panel is a powerful and adaptable solution that enables precise and efficient scaling of UV curing.

-

FAQs

Q1: What is a UV LED Flood Curing Panel used for?

A: A UV LED flood curing panel is used to cure UV-sensitive adhesives, coatings, and inks over large, flat surfaces in applications like PCB assembly, screen printing, and optical component processing.Q2: What are the key benefits of using a UV LED Flood Curing Panel?

A: It offers uniform UV intensity across the entire panel area, instant on/off functionality, low heat emission, long LED lifespan, and energy-efficient operation without mercury or ozone production.Q3: What wavelength options are available for the UV LED Flood Curing Panel?

A: Standard wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm, chosen based on the photoinitiator in the UV-curable material and desired curing performance.Q4: Can the UV LED Flood Curing Panel be integrated into an automated production process?

A: Yes, the panel can be integrated with conveyors, robotic systems, and PLC-controlled lines, making it suitable for inline and high-throughput curing environments.Q5: What maintenance is required for the UV LED Flood Curing Panel?

A: Maintenance includes regular cleaning of the optical surface, monitoring of the cooling system (air or water), and periodic output checks to ensure consistent and reliable performance.