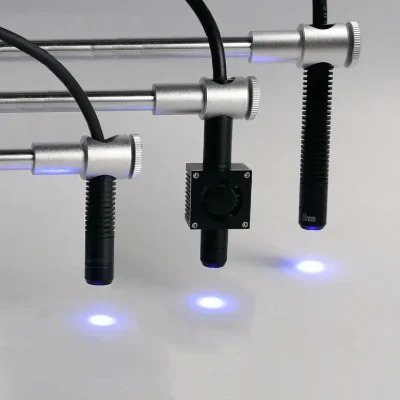

UV LED Spot Curing System

- Model: NSC4

- 365nm

- 385nm

- 395nm

- 405nm

The UV LED Spot Curing System delivers fast curing speeds, exceptional energy efficiency, and a long operational lifespan, making it ideal for industrial adhesive applications. It provides precise control over the curing process, emits minimal heat, and supports eco-friendly operation, ensuring both high performance and sustainability in demanding production environments.

- UV Wavelength: 365nm,385nm, 395nm, 405nm

- UV Spot Size: Φ3mm, Φ4mm, Φ5mm, Φ6mm

Specifications

| Model No. | NSC4 |

| UV Power Adjustable Range | 10~100% |

| Irradiation Channel | 4 channels; Independent running each channel |

| UV Spot Size | Φ3mm, Φ4mm, Φ5mm, Φ6mm,Φ8mm, Φ10mm,Φ12mm,Φ15mm |

| UV Wavelength | 365nm,385nm, 395nm, 405nm |

| UV LED Cooling | Natural / Fan cooling |

-

Descriptions

The UV LED Spot Curing System is built for fast, accurate curing in demanding production environments. With UV output up to 14W/cm², it ensures efficient energy delivery for UV-sensitive adhesives, coatings, and encapsulants. This system supports 365nm, 385nm, 395nm, and 405nm wavelengths to match a wide range of materials and process requirements.

Its compact, modular design makes it easy to integrate into both automated lines and benchtop stations, providing flexibility across applications in electronics, optics, and medical device assembly.

Features

- Versatile Application Range: Suitable for bonding, sealing, and coating in electronics, optics, and medical assemblies where accuracy and reliability are critical.

- High UV Intensity (Up to 14W/cm²): Delivers strong, focused UV energy that shortens curing cycles and improves production efficiency.

- Multiple Wavelength Options (365nm–405nm): Supports diverse UV-curable materials by allowing precise wavelength selection for optimal performance.

- Compact, Modular Design: Fits easily into existing setups with minimal disruption. Scalable from single-station use to multi-point automation.

- User-Friendly Interface: Streamlined controls reduce setup time, simplify operation, and shorten the training curve.

- Reliable, Consistent Performance: Maintains stable UV output across long production runs, ensuring uniform curing results and process repeatability.

Advantages of UV LED Spot Curing System

- Uniform spot coverage for complete, consistent curing

- Fast throughput with minimal heat buildup

- Flexible wavelength configuration for varied material needs

- Scalable for both manual and automated workflows

- Low maintenance and long LED lifespan

- Mercury-free, energy-efficient operation

Designed for Industrial Demands

This system is optimized for precision applications requiring fast, repeatable results. Unlike conventional mercury-based systems, it starts instantly, operates with low thermal impact, and eliminates the need for bulb replacement or long warm-up periods. These benefits lead to improved uptime, reduced operating costs, and a more sustainable process.

It also enables efficient integration with industrial control systems, offering I/O and programmable settings for seamless automation. Whether used in high-speed assembly lines or detail-focused lab environments, the system provides reliable performance across a wide range of tasks.

The UV LED Spot Curing System combines high intensity, wavelength versatility, and integration flexibility—making it a dependable choice for precision UV curing across various industries. Its performance and efficiency help meet production goals while ensuring consistent, high-quality results.

-

Applications

The NSC4 UV LED Spot Curing System is a powerful and versatile solution designed for precision curing applications across various industries. Delivering up to 14W/cm² of high-intensity UV output, this system ensures efficient and consistent curing for a wide range of materials. It supports multiple UV wavelengths—365nm, 385nm, 395nm, and 405nm—making it ideal for diverse curing requirements, from adhesives and coatings to inks and encapsulants.

Typical Applications

- Electronics: Wire tacking, PCB sealing, micro-assembly

- Optics: Lens bonding, fiber alignment

- Medical Devices: Catheter bonding, housing sealing

- Microfluidics & Sensors: Precision component bonding and encapsulation

What sets the UV LED Spot Curing System apart is its flexibility and adaptability. Designed for seamless integration into existing production lines, the NSC4 features a compact form factor and intuitive controls. This allows for easy installation and operation, minimizing downtime and maximizing productivity. Whether used in electronic assembly, optical component production, or medical device manufacturing, the NSC4 offers precise and reliable results.

A standout feature of this UV LED Spot Curing System is its suite of interchangeable focusing lenses, enabling users to concentrate UV intensity exactly where it’s needed. This precision enhances curing performance, ensuring uniform results even in the most demanding applications. The focused output not only improves process control but also supports high-quality, repeatable outcomes critical to modern manufacturing.

With its robust energy output, multi-wavelength flexibility, and user-friendly design, the NSC4 UV LED Spot Curing System redefines what’s possible in spot curing. Manufacturers rely on it for its reliability, efficiency, and adaptability to a wide range of curing tasks. Whether bonding, sealing, or fixing components, the NSC4 delivers the performance and consistency needed for today’s high-precision applications.

-

FAQs

Q1: What applications can the UV LED Spot Curing System be used for in industrial manufacturing?

A: The UV LED Spot Curing System is ideal for precision curing in electronics assembly, medical devices, optical bonding, and microfluidic components.Q2: Which wavelengths are available for the UV LED Spot Curing System, and how do I choose the right one?

A: Available wavelengths include 365 nm, 385 nm, 395 nm, and 405 nm; selection depends on the material’s photoinitiator and desired cure depth.Q3: Is the UV LED Spot Curing System compatible with automated or PLC-controlled production lines?

A: Yes, it supports PLC integration, external triggering, and I/O communication for seamless automation and high-throughput environments.Q4: What is the expected operational lifespan of the UV LED Spot Curing System and its maintenance needs?

A: The system offers over 20,000 hours of LED life under standard conditions with minimal maintenance—mainly optical cleaning and periodic checks.Q5: How does the UV LED Spot Curing System ensure consistent curing performance and process control?

A: It provides adjustable intensity, exposure time, and cycle control via digital interface, along with monitoring features for process repeatability.