How to Calculate UV Dose for LED Curing (Intensity × Time)

In industrial manufacturing, achieving a consistent, high-quality finish depends on more than just turning on the light. To ensure your adhesives, inks, or coatings reach their full structural integrity, you must understand the relationship between the power of your lamp and the duration of exposure.

This technical guide focuses on the fundamental metric of UV dose, providing you with the exact formulas and practical insights needed to calibrate your production line. By mastering these calculations, you can eliminate common defects like surface tackiness or delamination, ensuring every part that leaves your facility is perfectly cured and ready for the next stage of assembly.

What Is UV Dose in LED Curing?

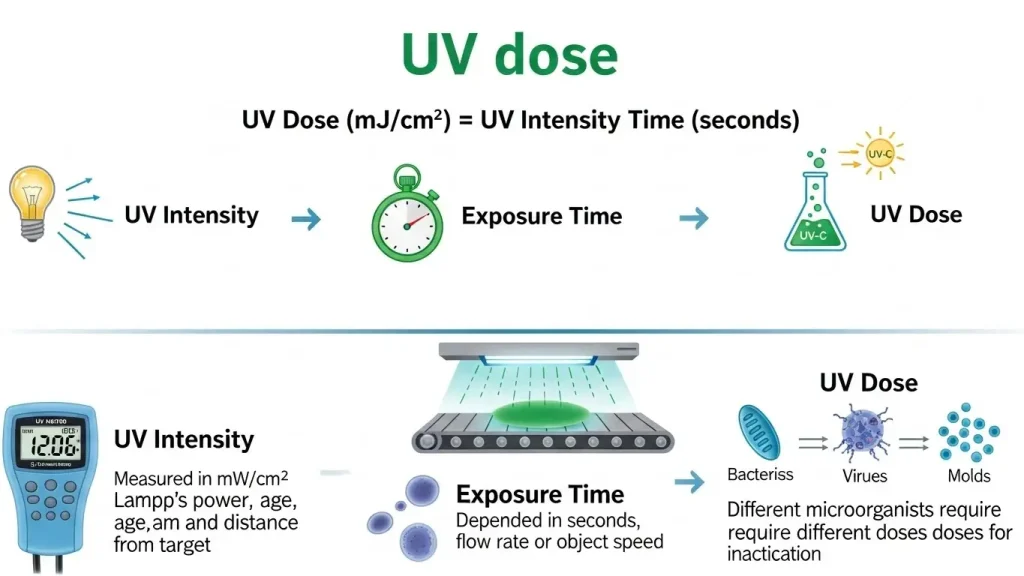

UV dose in LED curing refers to the total amount of UV energy delivered to a surface over a defined exposure period. You should think of it as the cumulative energy that your material absorbs, rather than just the "brightness" of the lamp at a single moment.

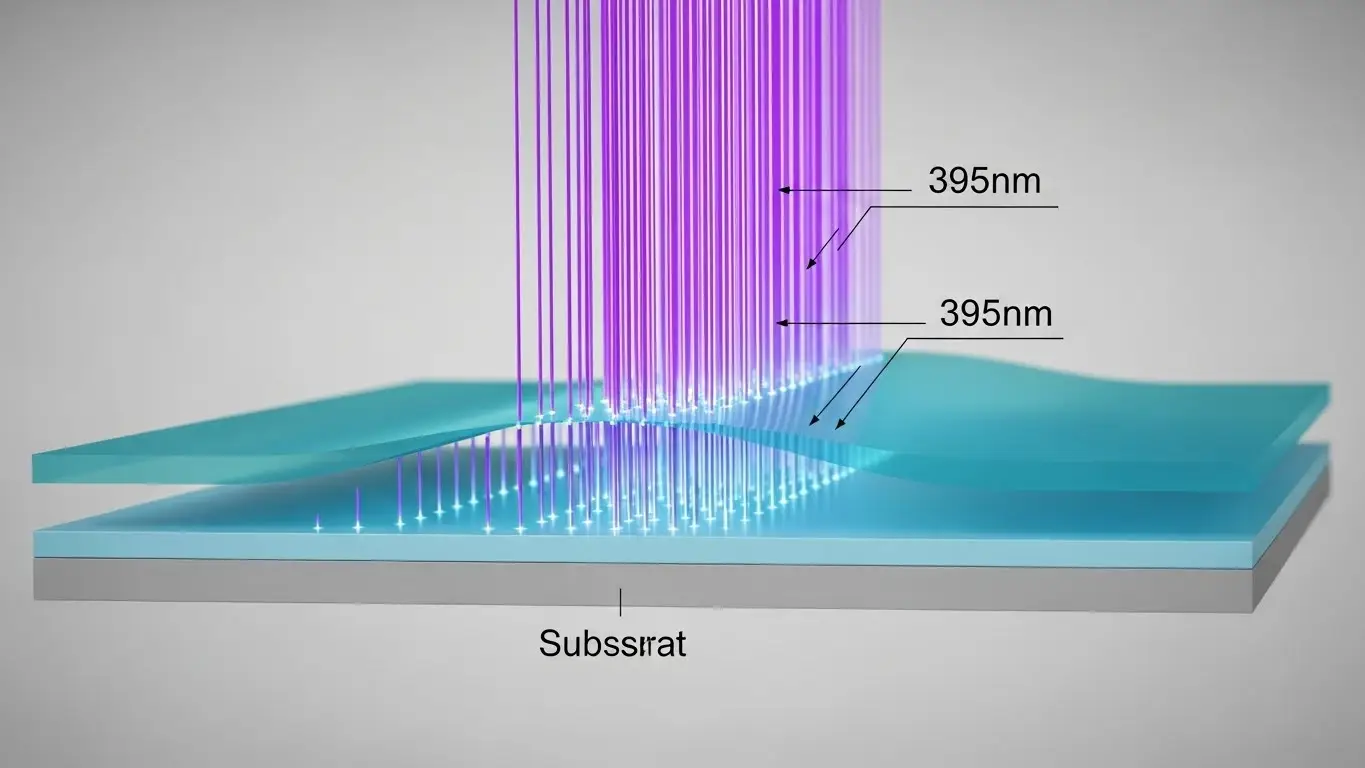

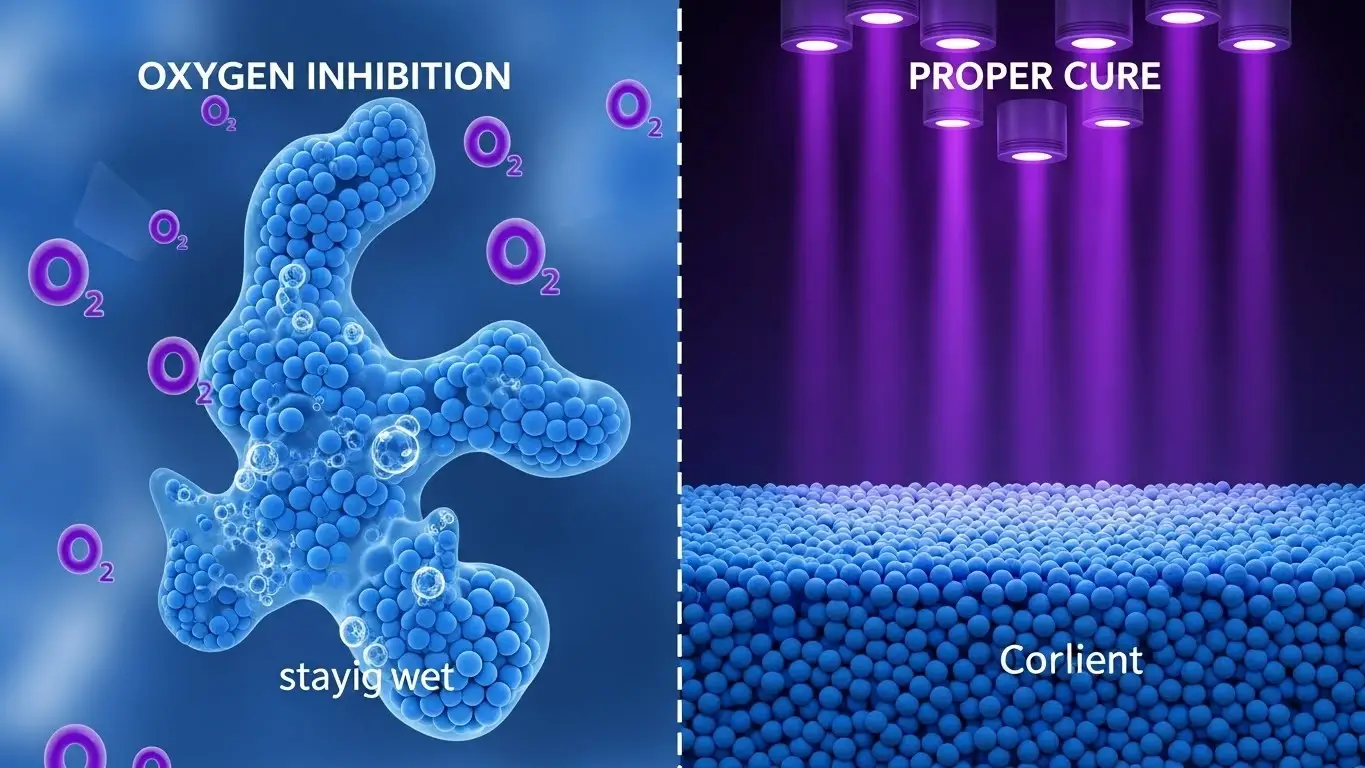

While intensity provides the peak power required to "shock" photoinitiators and start the reaction, the dose determines if there is enough total energy to complete the molecular cross-linking across the entire thickness of your coating. Without a sufficient dose, the chemical reaction may stall, resulting in a part that is dry on top but remains liquid at the base.

How Is UV Dose Calculated Using Intensity and Time?

UV dose is calculated by multiplying UV intensity by exposure time, typically expressed in the following scientific formula:

$$E = P \cdot t$$

In this equation, $E$ represents the energy density or dose ($J/cm^2$), $P$ represents the irradiance or intensity ($W/cm^2$), and $t$ is the exposure time in seconds. For example, if your lamp delivers an intensity of 2 W/cm² and the part remains under the light for 3 seconds, the resulting dose is 6 J/cm².

This calculation is a critical tool for production engineers because it allows you to adjust your conveyor speed or lamp power proportionally to maintain a consistent energy level. Even as production demands shift, the formula ensures that the chemical requirements of your resin are consistently met.

Why Is UV Dose More Important Than Intensity Alone?

UV dose matters more than intensity alone because curing depends on total delivered energy, not just instantaneous power. You may have a very high-intensity lamp, but if the part passes under it too quickly, the total energy might be insufficient to achieve a full "through-cure."

This is particularly true for thick or pigmented materials where the photons must travel through many layers to reach the substrate. Conversely, a lower-intensity lamp can often achieve a perfect result if given enough dwell time, as the total dose eventually reaches the required threshold for your specific material chemistry.

How Does Exposure Time Affect UV Dose in Production?

Exposure time directly affects UV dose because longer dwell times increase total energy delivered even at the same intensity. In a conveyorized system, your exposure time is a function of the belt speed and the physical length of the UV lamp's curing window.

If you double your line speed, you effectively cut your exposure time and your delivered dose in half. You must carefully calibrate your machine speeds and document them as part of your standard operating procedures to ensure that every part receives the minimum energy dose required by your material supplier.

How Should You Match UV Dose to Material Requirements?

Matching UV dose to material requirements involves understanding cure sensitivity and verifying performance through testing rather than relying on generic values. You should follow these practical steps to align your process with your material's specific needs:

- Review the Technical Data Sheet (TDS): Locate the manufacturer's recommended joules per square centimeter.

- Conduct Ladder Studies: Test your material at various speeds and power levels to find the optimal "process window."

- Perform Adhesion Tests: Use cross-hatch or solvent-rub tests on finished parts to confirm structural cure.

- Account for Pigmentation: Denser or darker materials usually require a significantly higher dose to cure the base layer effectively.

What Factors Can Reduce the Effective UV Dose Delivered?

Effective UV dose can be reduced by factors such as uneven intensity distribution, thermal effects, lamp aging, or improper system setup. You might find that even if your lamp is rated for a certain power, dirt on the lens or an increase in internal lamp temperature can cause the actual intensity to drop.

As intensity falls, the resulting dose decreases proportionally. It is vital to measure the energy at the part surface regularly using a calibrated radiometer to account for these real-world losses. These variances are not always visible to the naked eye but can lead to significant quality failures if left unchecked.

How Can You Verify UV Dose in Real Applications?

Verifying UV dose in real applications involves measuring intensity, confirming exposure time, and validating cure performance on the finished part. You should use a radiometer specifically designed for LED wavelengths to map the energy levels across your conveyor belt.

Monitoring these values during production shifts allows you to detect if a lamp is failing or if your conveyor speed has drifted. This validation process turns your curing cycle from a "best guess" into a data-driven manufacturing step, preventing the shipment of under-cured products.

What Are the Key Takeaways for Calculating UV Dose?

The most successful curing processes rely on a precise understanding of the relationship between power and time. You get the most reliable results when you treat the UV dose as your primary metric for quality control and process repeatability.

- Dose is Total Energy: Always measure in $J/cm^2$ to ensure through-cure.

- Fundamental Formula: Remember that $Energy = Intensity \times Time$.

- Speed is Critical: Adjusting conveyor speed is the most common way to control dose in an industrial setting.

- Measurement is Key: Use a radiometer to confirm that the lamp is delivering what the data sheet promises.

What System Specifications Influence UV Dose Delivery?

You can learn more about how lamp design impacts energy output on our guide to UV LED curing system specs.

How Is UV LED Dose Calculated in Practice?

For more detailed examples and technical nuances, visit our page on UV LED curing dose calculation.

How Does Intensity Uniformity Affect Delivered Dose?

If your lamp has "cold spots," your dose will be inconsistent across the part. Read about UV LED curing uniformity for more details.

How Does Lamp Temperature Influence UV Dose?

Heat can cause a drop in light intensity, which directly lowers your dose. Explore the relationship between lamp temperature and UV performance.

What Maintenance Factors Impact UV Dose Consistency?

Dirty lenses or worn-out diodes can reduce your energy delivery. Follow our maintenance guide to keep your dose in spec.

How Do Cooling Methods Affect UV Dose Stability?

Maintaining a stable dose requires precise thermal management. Compare water-cooled systems and air-cooled lights.

What Defines a High-Power UV LED Curing System?

For applications requiring a massive dose in a short time, learn about high-power UV LED curing systems.

Final Thoughts on UV Dose Calculation

Calculating the correct UV dose is the bridge between theoretical chemistry and successful manufacturing. While the formula itself is simple, its application requires constant vigilance regarding your equipment's health and the environmental conditions of your factory floor.

By prioritizing the total energy delivered ($J/cm^2$) over simple intensity ratings, you ensure that every bond is permanent and every coating is durable. As your production demands grow, this data-driven approach will allow you to scale your speeds with confidence, knowing exactly how to adjust your parameters to maintain a perfect cure every time.