UV LED Curing for UV Varnish: How It Works

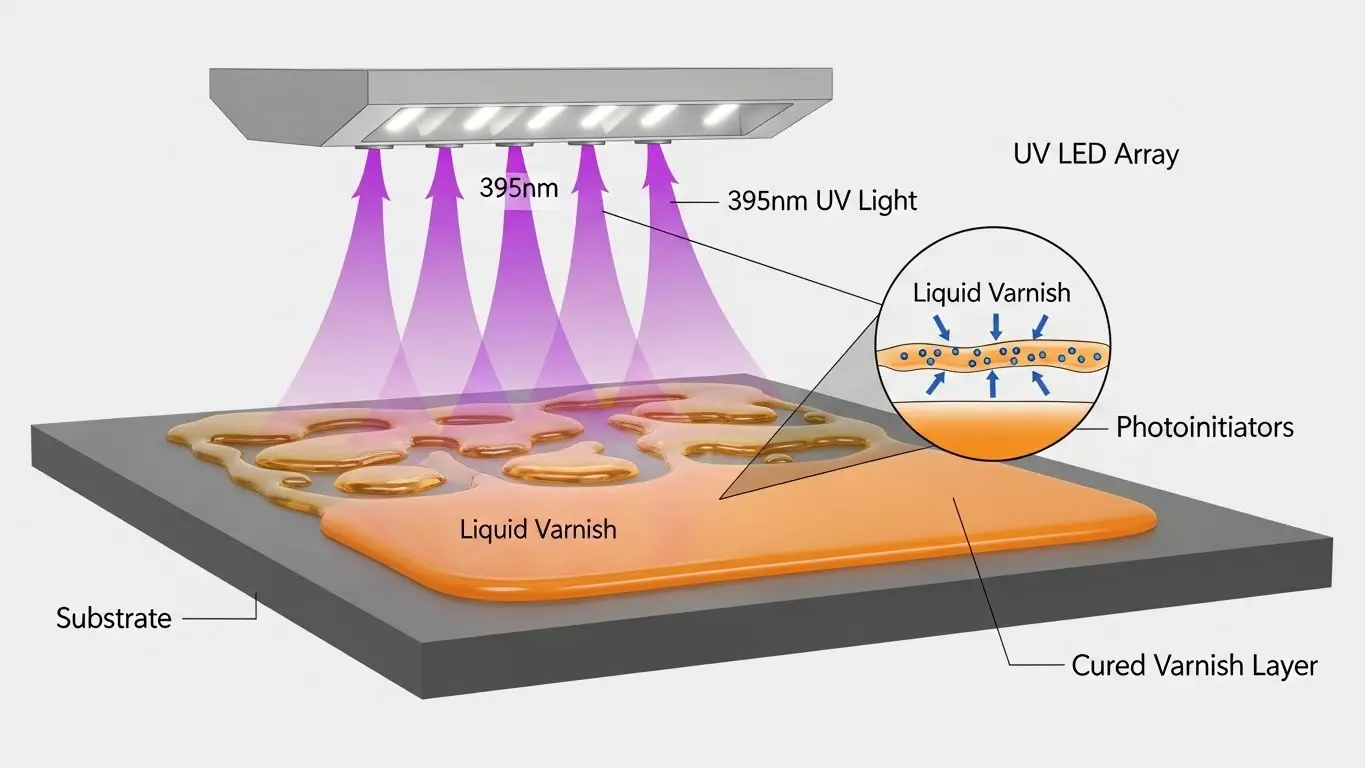

UV LED curing for UV varnish is a photopolymerization process that uses light-emitting diodes (LEDs) to instantly dry and harden liquid varnishes. Unlike traditional drying methods that rely on heat or evaporation, UV LED systems emit specific wavelengths of ultraviolet light—typically 365nm, 385nm, or 395nm—which trigger photoinitiators within the varnish. This reaction causes the liquid oligomers and monomers to cross-link almost immediately, forming a durable, high-gloss, or matte solid film. This technology is widely adopted in printing and packaging because it generates significantly less heat, consumes less energy, and eliminates the release of volatile organic compounds (VOCs), making it safer for heat-sensitive substrates like thin films and plastics.

What is UV LED Curing Technology?

UV LED curing is the modern standard for solidifying industrial coatings and inks. At its core, it replaces the broad-spectrum bulbs of the past with focused, high-intensity electronic light sources.

For varnishes specifically, the process relies on a chemical "lock and key" mechanism. The varnish is formulated with specific photoinitiators designed to absorb the exact narrow band of UV light that the LED lamp emits. When the light hits the wet varnish, it triggers a chain reaction that solidifies the coating in milliseconds. Because the LEDs turn on and off instantly without a warm-up period, this method is highly efficient for production lines requiring stop-and-go capabilities.

The Role of Wavelengths

Not all UV light is the same. UV LED curing typically operates in the UVA range. The most common wavelength for varnishes is 395nm because it offers excellent depth of cure, penetrating through thicker layers of clear varnish to ensure adhesion to the substrate below.

For a deeper dive into how this technology applies to various industrial layers, you can explore UV LED Curing for Coatings to see how the science scales across different applications.

How Does UV LED Curing Compare to Mercury Lamps?

Is UV LED curing better than traditional mercury lamps?

Yes, for most modern applications, UV LED curing is superior due to lower energy consumption, longer lifespan, and reduced heat output. While mercury lamps are still used for certain broad-spectrum formulations, LED is rapidly becoming the industry preference.

Energy Efficiency and Heat Management

Traditional mercury arc lamps produce massive amounts of infrared heat (IR), which can distort thin substrates like shrink sleeves or thermal labels. UV LED systems emit "cold curing" energy—there is very little IR transfer. This allows printers to apply varnish to delicate materials without warping them. Furthermore, LEDs can save up to 70% in energy costs because they are only powered on when curing is actively happening.

Equipment Lifespan

- Mercury Lamps: Typically last 1,000–2,000 hours and degrade over time.

- UV LEDs: Can last over 20,000 hours with consistent output intensity.

| Feature | UV LED Curing | Traditional Mercury Arc |

| Heat Output | Low (Cold Cure) | High (Requires intense cooling) |

| Warm-up Time | Instant On/Off | 10-20 Minutes |

| Energy Use | Low | High |

| Ozone Generation | None | Yes (Requires extraction) |

| Substrate Safety | Excellent for heat-sensitive materials | Risk of warping |

What Types of Varnish Can Be Cured with LED?

Can I use any UV varnish with an LED lamp?

No, you cannot use standard UV varnish with an LED lamp; you must use varnish specifically formulated for LED curing. Standard varnishes are designed for broad-spectrum light, whereas LED varnishes are tuned to react to specific narrow wavelengths (like 395nm).

Formulation Matters

If you try to cure a standard mercury-formulated varnish with an LED lamp, it will likely remain tacky or wet. The photoinitiators in the standard varnish won't "see" the light from the LED. However, "dual-cure" varnishes are available that work with both systems.

When selecting materials, it is critical to verify compatibility. To learn more about material suitability, check out this guide on What Coatings Can Be Cured with UV LED?, which covers various substrates and chemical compositions.

Common Issues: Why Is My UV Varnish Sticky?

Why does my UV varnish feel tacky after curing?

A sticky or "tacky" surface usually indicates that the varnish suffered from "oxygen inhibition" or the UV dose was insufficient. Oxygen in the air can interfere with the curing reaction at the very top surface of the varnish layer.

How to Fix Oxygen Inhibition

In UV LED curing, the light intensity (irradiance) must be high enough to overcome the oxygen barrier.

- Increase Power: Ensure your LED array is running at sufficient intensity.

- Check Distance: The lamp should be mounted close to the substrate (usually 5mm–20mm). As distance increases, energy density drops rapidly.

- Reformulate: Use high-reactivity varnishes designed specifically to resist oxygen inhibition.

Frequently Asked Questions

What is the difference between UV coating and UV varnish?

While often used interchangeably, "varnish" typically refers to the clear liquid applied on a printing press (like an ink unit) for spot or flood effects. "UV coating" often refers to a flood application done off-line or on a dedicated coater unit for protection. Chemically, they are very similar, but the application method differs.

Is UV LED curing safe for food packaging?

Yes, provided "low-migration" varnishes are used. Because UV LED cures instantly and thoroughly, there is a lower risk of unreacted chemicals migrating into food compared to solvent-based inks. However, strict adherence to GMP (Good Manufacturing Practices) is required.

How long does UV LED varnish take to cure?

It is virtually instantaneous. The reaction occurs in a fraction of a second as the substrate passes under the LED array. This allows production speeds of up to 500+ feet per minute depending on the equipment.

Key Takeaways

- Wavelength Matching: You must use varnishes formulated specifically for the LED wavelength (usually 395nm) to ensure a proper cure.

- Heat Reduction: UV LED puts significantly less heat into the substrate, allowing for varnishing on thin films and shrink wraps.

- Energy Savings: The "instant on/off" capability eliminates standby energy consumption, drastically reducing operational costs.

- Oxygen Inhibition: If the surface is tacky, check your lamp distance and intensity; higher intensity is needed to cure the surface layer fully.

Conclusion

UV LED curing for UV varnish represents a significant leap forward in finishing technology. By moving away from heat-intensive mercury lamps to cool, energy-efficient LEDs, manufacturers can increase throughput and work with a wider range of materials.

If you are transitioning to UV LED, start by auditing your current varnish inventory to ensure wavelength compatibility. The switch not only improves your environmental footprint but often results in a more consistent, higher-quality finish.