What UV Intensity Do I Need for Curing? (W/cm² Explained)

Determining what UV intensity do I need for curing is a fundamental step in optimizing any industrial ultraviolet process. You will find that the intensity of your light source dictates how effectively the photoinitiators in your resins are triggered, directly impacting your production speed and part quality.

This guide explains the technical definition of intensity ($W/cm^2$), its relationship to energy dose, and the practical factors that influence how much power actually reaches your substrate. By understanding these metrics, you can better specify your equipment and ensure a reliable, repeatable cure for your specific application.

What Does UV Intensity (W/cm²) Actually Mean?

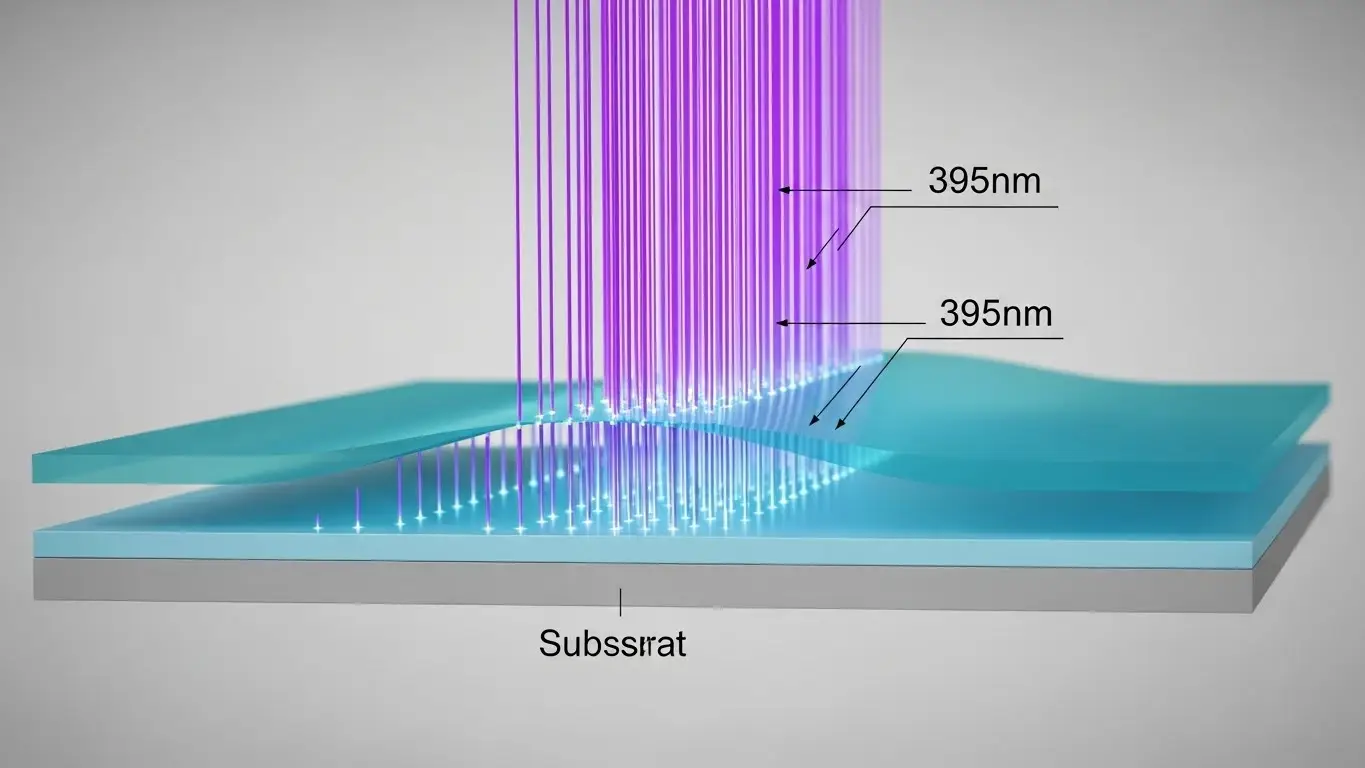

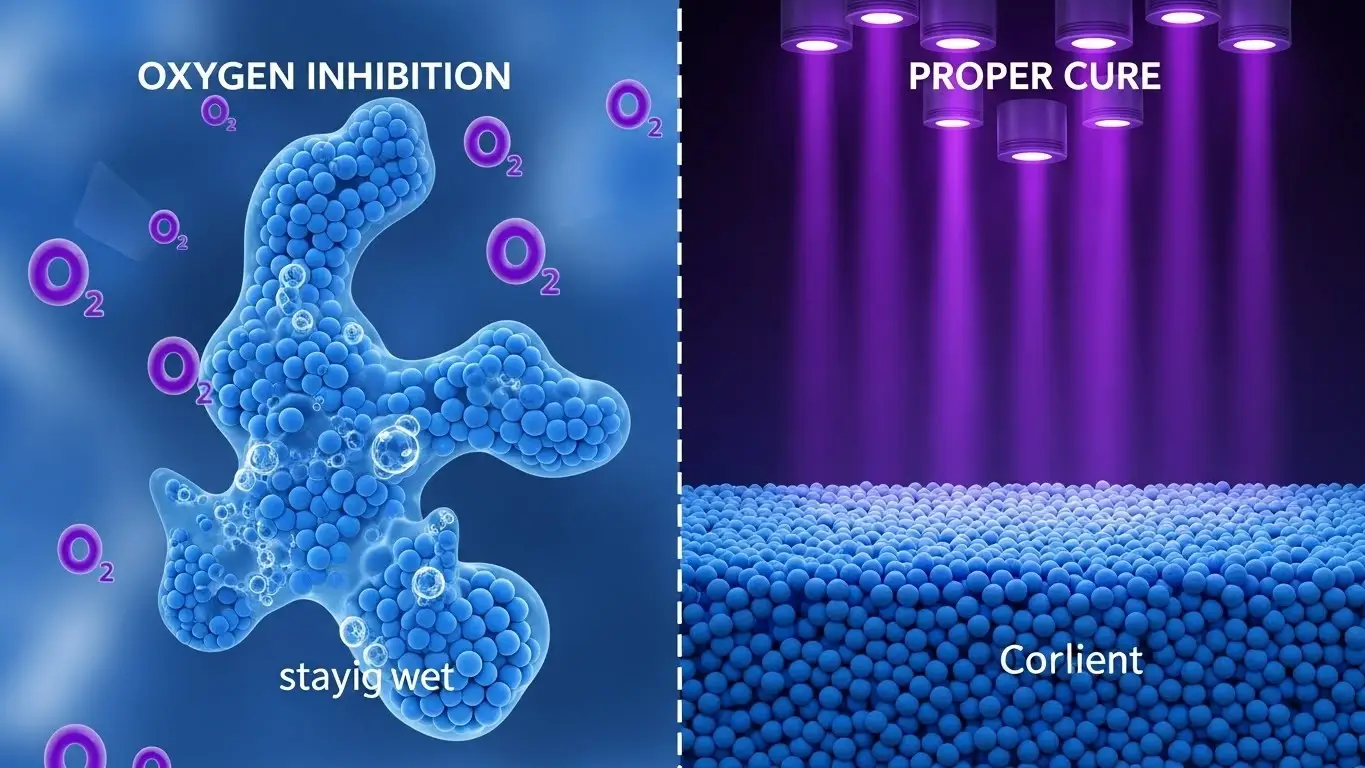

UV intensity, measured in watts per square centimeter ($W/cm^2$), describes how much UV energy a curing system delivers per unit area at a given moment. You can think of intensity as the "brightness" or "pressure" of the UV light hitting the surface of your part. It is an instantaneous measurement of power density, representing the concentration of photons available to start the chemical reaction. Unlike total energy, intensity tells you the strength of the light at a specific working distance from the lamp head, which is critical for overcoming oxygen inhibition in certain coatings.

How Does Intensity Affect the Curing Process?

UV intensity influences how quickly and uniformly a material can cure because the energy delivered at any instant affects the rate of photochemical reaction. You will find that higher intensity levels often lead to faster polymerization, which can support higher conveyor speeds and increased throughput. This instantaneous energy is what "shocks" the photoinitiators into a reactive state, ensuring that the cure starts consistently across the entire surface of your coating. Proper intensity levels also help in achieving better surface hardness by ensuring the top layer sets before atmospheric oxygen can interfere with the chemistry.

How Is UV Intensity Different From UV Dose?

UV dose, measured in joules per square centimeter ($J/cm^2$), combines intensity with exposure time, whereas intensity alone measures instantaneous power. You must distinguish between these two because a high-intensity lamp used for a fraction of a second may deliver the same dose as a low-intensity lamp used for several seconds, but the cure results may be entirely different. Intensity provides the "spark" to start the reaction, while the dose represents the total amount of energy required to complete the hardening process through the entire thickness of the material.

What Intensity Levels Are Typical for UV LED Curing?

Typical UV LED curing intensities can vary widely depending on system design, process speed, and material needs, with moderate industrial systems often specified in certain $W/cm^2$ bands. You might see entry-level or manual systems providing intensities between 1 and 4 $W/cm^2$, which are sufficient for many thin-film adhesives and clear coats. High-speed automated lines, such as those used in digital printing or narrow-web labels, often require much higher intensities, sometimes exceeding 16 or 20 $W/cm^2$, to ensure a full cure within a very small exposure window.

How Should You Match Intensity to Material and Application?

Matching intensity to material and application involves understanding the material’s cure sensitivity and balancing intensity with exposure time and movement speed. You should always start by reviewing the technical data sheet for your specific ink or adhesive to identify the manufacturer's recommended irradiance levels.

- Audit Material Requirements: Identify the minimum $W/cm^2$ needed to trigger your specific photoinitiators.

- Evaluate Line Speed: Calculate the required intensity based on how long each part will be under the lamp.

- Test for Surface Hardness: Verify that the intensity is high enough to overcome oxygen inhibition for a tack-free finish.

- Check Penetration Depth: Ensure the intensity is sufficient to travel through pigmented or thick layers.

- Run Ladder Studies: Perform tests at varying intensity levels to find the optimal "process window."

What Practical Considerations Affect Intensity Delivery?

Practical delivery of UV intensity depends on factors such as energy uniformity across the target area, lamp temperature control, cooling strategy, and system layout. You will notice that as a lamp head gets farther from the part, the intensity drops off significantly; maintaining a consistent working distance is vital for a repeatable process. Additionally, if your cooling system is inadequate, the LED diodes may heat up, causing their output intensity to decay over the course of a production shift. The optical design of the lamp also determines how the energy is concentrated on your parts.

What Misconceptions Should You Avoid About UV Intensity?

Common misconceptions include assuming that higher intensity always improves cure or that intensity alone determines curing success without considering dose, material chemistry, or uniformity. You might think that doubling the intensity will automatically allow you to double your line speed, but some materials have a "saturation point" where extra intensity simply generates excess heat without speeding up the cure. Another frequent mistake is over-relying on the lamp's rated peak intensity; in reality, the intensity at the part surface is often much lower due to distance and lens efficiency.

What Are the Key Takeaways on UV Intensity for Curing?

Achieving a perfect cure requires you to treat UV intensity as one part of a larger technical equation. You get the best results when you match the instantaneous power of your lamp to the chemical needs of your material and the mechanical speed of your line.

- Intensity ($W/cm^2$) is the instantaneous power; Dose ($J/cm^2$) is the total energy.

- Higher intensity generally supports faster line speeds and better surface hardness.

- The effective intensity at the part drops as the working distance increases.

- Always validate your process with a radiometer to ensure consistent power delivery.

What Specifications Should You Look at in a UV LED Curing System?

Intensity is just one piece of the puzzle. You can learn how it relates to power, cooling, and footprint in our guide on UV LED curing system specs.

How Is UV LED Dose Calculated From Intensity?

Understanding the math behind your process helps you maintain quality. Review how UV LED dose is calculated to see how intensity and time work together.

How Does Uniformity Affect Curing Quality?

High intensity is only useful if it is consistent across the part. Read about why UV LED curing uniformity is essential for avoiding soft spots in your finish.

How Does Lamp Temperature Influence Intensity and Performance?

Heat is the enemy of stable UV output. Explore the relationship between lamp temperature and intensity to see why cooling is a critical specification.

What Maintenance Practices Support Consistent Intensity?

Lamps can lose intensity due to dirt or aging. Follow our maintenance guide to keep your system performing at its rated specification.

How Do Cooling Strategies Affect Intensity Delivery?

High-intensity lamps require robust thermal management to stay stable. Check out the differences between water-cooled systems and air-cooled lights for your intensity needs.

What Defines a High-Power UV LED Curing System?

For the most demanding applications, you may need a specialized setup. Learn what constitutes a high-power UV LED curing system and when you might need one.

Final Thoughts

Finalizing your intensity requirements is a balancing act between the chemical needs of your resin and the physical constraints of your line. While high-intensity lamps offer the promise of faster production, they must be supported by adequate cooling and precise process control to be effective. By focusing on the irradiance reaching the part surface and measuring it regularly with a radiometer, you can eliminate the guesswork from your curing process. The best intensity level is the one that provides a consistent, high-quality bond without adding unnecessary heat or cost to your manufacturing workflow.