How Hot Does a UV LED Curing Lamp Get?

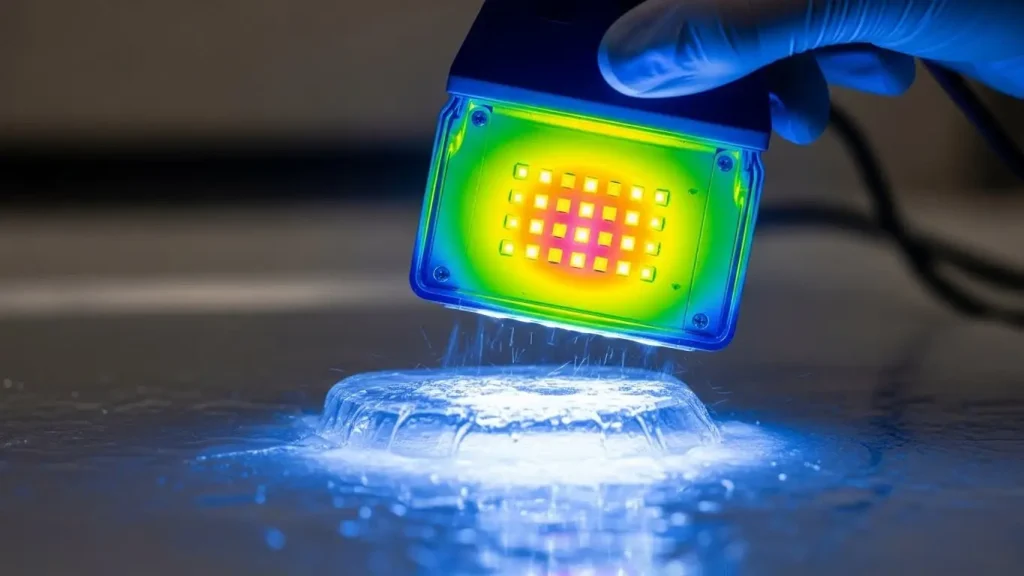

Managing thermal output is a critical requirement for maintaining a stable and repeatable industrial curing process. While UV LEDs are often marketed as "cool" light sources compared to traditional mercury lamps, they still generate significant internal heat that must be actively dissipated.

This guide examines how hot a UV LED curing lamp gets by looking at junction temperatures, housing surface heat, and the impact of various cooling strategies. By understanding these thermal dynamics, you can better protect your equipment from premature failure and ensure your materials receive a consistent dose of ultraviolet energy every shift.

What Determines How Hot a UV LED Curing Lamp Gets?

The temperature a UV LED curing lamp reaches depends on electrical input, heat generated during operation, how effectively heat is removed, and the specific design of the unit. You will find that only about 15% to 30% of the electrical energy consumed by the diodes is converted into usable UV light, while the remaining energy is converted into thermal waste. The efficiency of the internal heat sink and the thermal interface materials used between the LED board and the housing dictate how quickly this heat is pulled away from the semiconductor chips. Ambient environment factors, such as factory air temperature and airflow restrictions, also play a significant role in determining the final equilibrium temperature of the lamp.

What Temperatures Can You Expect During Operation?

UV LED curing lamps can run significantly warmer than ambient air and that LED junctions often operate at elevated temperatures under load, with housing surfaces also feeling warm to hot depending on cooling. In a well-designed industrial system, the housing surface typically remains between 40°C and 60°C, though this can vary based on intensity settings. The internal LED junction—the actual point where light is created—operates at much higher temperatures, often reaching 80°C to 120°C. Maintaining these junction temperatures below the manufacturer's maximum rating is vital to prevent permanent damage to the diode structure and to avoid a shift in the emitted wavelength.

Why Does Lamp Temperature Matter for Performance and Life?

Lamp temperature matters because excessive heat can reduce UV output stability, alter intensity distribution, and shorten LED life if not properly managed. You will notice that as an LED chip gets hotter, its light-emitting efficiency drops, which directly results in a lower UV intensity reaching your part. This phenomenon, known as thermal decay, can lead to under-cured products if your process was calibrated when the lamp was cold. Furthermore, operating at consistently high temperatures accelerates the degradation of the diode encapsulants and bonding wires, potentially reducing the lamp's expected 20,000-hour lifespan.

How Do Cooling Methods Influence Lamp Temperature?

Cooling methods strongly influence how hot a UV LED curing lamp runs, with active air or water cooling removing heat more effectively than passive approaches. Air-cooled systems use high-speed fans to pull heat from aluminum fins, which is effective for low-to-medium power applications but relies heavily on the cleanliness of the intake filters. Water-cooled systems utilize a recirculating liquid chiller to provide much higher thermal transfer rates, allowing the lamp to maintain a lower and more consistent temperature even at extreme power levels. Because liquid cooling is more aggressive, it enables the use of higher-density LED arrays without the risk of thermal runaway.

How Does Intensity and Power Affect Operating Temperature?

Increased intensity and system power typically raise operating temperature because higher electrical input generates more thermal energy that must be dissipated. When you increase the drive current to achieve a higher irradiance ($W/cm^2$), the internal resistive heating of the diodes increases proportionally. If your cooling system is not scaled to handle this increased thermal load, the lamp will quickly reach a "thermal ceiling" where further power increases actually result in lower UV output due to efficiency losses. You must ensure that your intensity settings remain within the cooling capacity of the hardware to maintain a stable process window.

What Practical Steps Can Help Manage Lamp Heat?

Practical steps to manage lamp heat include ensuring effective cooling, proper airflow, routine maintenance, and using system specs that align with duty cycles and environmental conditions. You can achieve better thermal stability by implementing a structured monitoring routine:

- Monitor Ambient Air: Ensure your facility's temperature does not exceed the lamp's rated operating environment.

- Inspect Cooling Paths: Clean air filters and check for kinks in water lines to maintain maximum flow rates.

- Validate Thermal Stability: Use a radiometer to confirm that the UV output remains steady after the lamp has reached operating temperature.

- Check Thermal Paste: In older units, ensure the thermal interface between the LED board and heat sink has not degraded.

- Optimize Duty Cycles: Use the "instant-on/off" capability of LEDs to turn off lamps between parts, reducing total heat buildup.

What Misconceptions Exist About UV LED Lamp Heat?

Common misconceptions about UV LED lamp temperature include believing they don’t run hot or that higher temperatures always improve curing without risks to stability or life. While it is true that LEDs do not project infrared (IR) heat onto the substrate like mercury lamps, the hardware itself produces substantial heat that must be moved away from the chips. Another myth is that "LEDs are 100% efficient"; in reality, they are thermal-heavy devices that require robust engineering to survive industrial use. Assuming that a lamp "feels fine" on the outside does not guarantee that the internal junctions are operating within safe technical limits.

What Are the Key Takeaways on UV LED Curing Lamp Temperature?

Successfully managing UV LED heat is the only way to guarantee the long-term repeatability of your curing process. You get the most reliable results when you prioritize thermal management as a core specification of your manufacturing line.

- LED hardware generates significant internal heat despite projecting a "cold" beam onto parts.

- High junction temperatures lead to UV output decay and shortened equipment life.

- Water cooling offers the best thermal stability for high-intensity industrial applications.

- Regular maintenance of cooling systems is essential for preventing long-term process drift.

What Specifications in a UV LED Curing System Relate to Temperature?

Thermal management is tied directly to power and footprint. Learn how these relate in our guide on UV LED curing system specs.

How Do Water-Cooled Systems Affect Lamp Temperature?

Liquid cooling provides the most aggressive heat removal for industrial setups. Read about the design of water-cooled UV LED systems for more details.

How Do Air-Cooled vs Water-Cooled UV LED Systems Compare for Heat Control?

Choosing the right cooling method depends on your intensity needs. See a side-by-side comparison of cooling methods for thermal performance.

How Does Intensity Influence Thermal Output?

Higher irradiance leads directly to increased heat generation. Explore the technical relationship of UV LED intensity and heat.

How Is UV LED Dose Related to Heat in a Curing System?

Total energy delivery and runtime determine accumulated heat. Learn about UV LED dose calculation to manage your duty cycles.

How Does Uniformity Impact Temperature Distribution?

Uneven light output can create localized thermal hot spots. Review why UV LED curing uniformity matters for system health.

How Does System Maintenance Influence Lamp Temperature?

Dirty filters or clouded lenses can trap heat and reduce efficiency. Follow our maintenance guide to keep temperatures in check.

What Should You Know About High-Power UV LED Curing Systems and Heat?

Massive intensity requires specialized thermal engineering. Explore the needs of high-power UV LED curing systems.

Final Thoughts on Lamp Temperature

Finalizing your understanding of lamp temperature allows you to move from a "reactive" maintenance style to a "proactive" quality control process. While it is tempting to focus only on the UV intensity of a lamp, its ability to manage heat is what determines if that intensity will still be there six months from now. By ensuring your cooling strategy is matched to your production demands, you eliminate the risk of thermal decay and secure the long-term stability of your manufacturing bond. A cool-running lamp is a reliable lamp, providing the consistency needed for high-volume success.