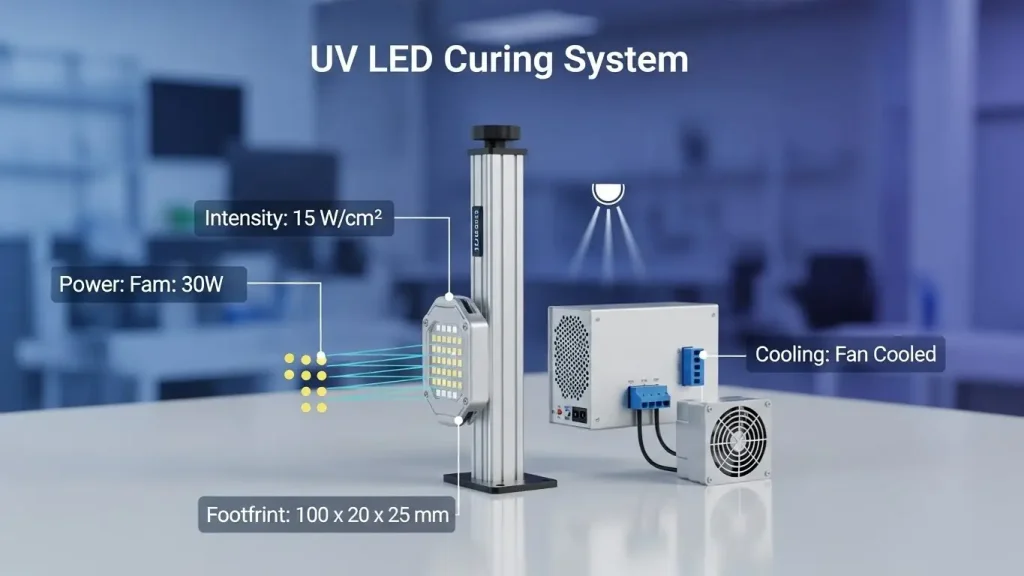

UV LED Curing System Specs: Power, Intensity, Cooling, and Footprint

Evaluating UV LED curing system specs is a technical requirement for any engineer looking to integrate ultraviolet technology into a production environment. You must look beyond simple marketing numbers to understand how the relationship between energy output and thermal management dictates your final part quality.

This guide breaks down the essential specifications of power, intensity, cooling, and physical footprint to help you align equipment capabilities with your material requirements. By mastering these metrics, you can ensure a stable, repeatable curing process that maximizes both throughput and equipment longevity.

What Are the Core Power Specifications of a UV LED Curing System?

Core power specifications for a UV LED curing system describe how much electrical energy the system can convert into usable UV output and influence cure capability and throughput. You will find that these ratings typically reflect the total wattage consumption of the LED array and the efficiency of the drivers.

While total power is a useful baseline, it does not represent the actual light intensity reaching your part; instead, it indicates the system's capacity to drive multiple diode banks at peak levels. Understanding the input power requirements helps you plan your facility’s electrical load and evaluate the overall efficiency of the light engine.

What Does UV Intensity and Irradiance Tell You?

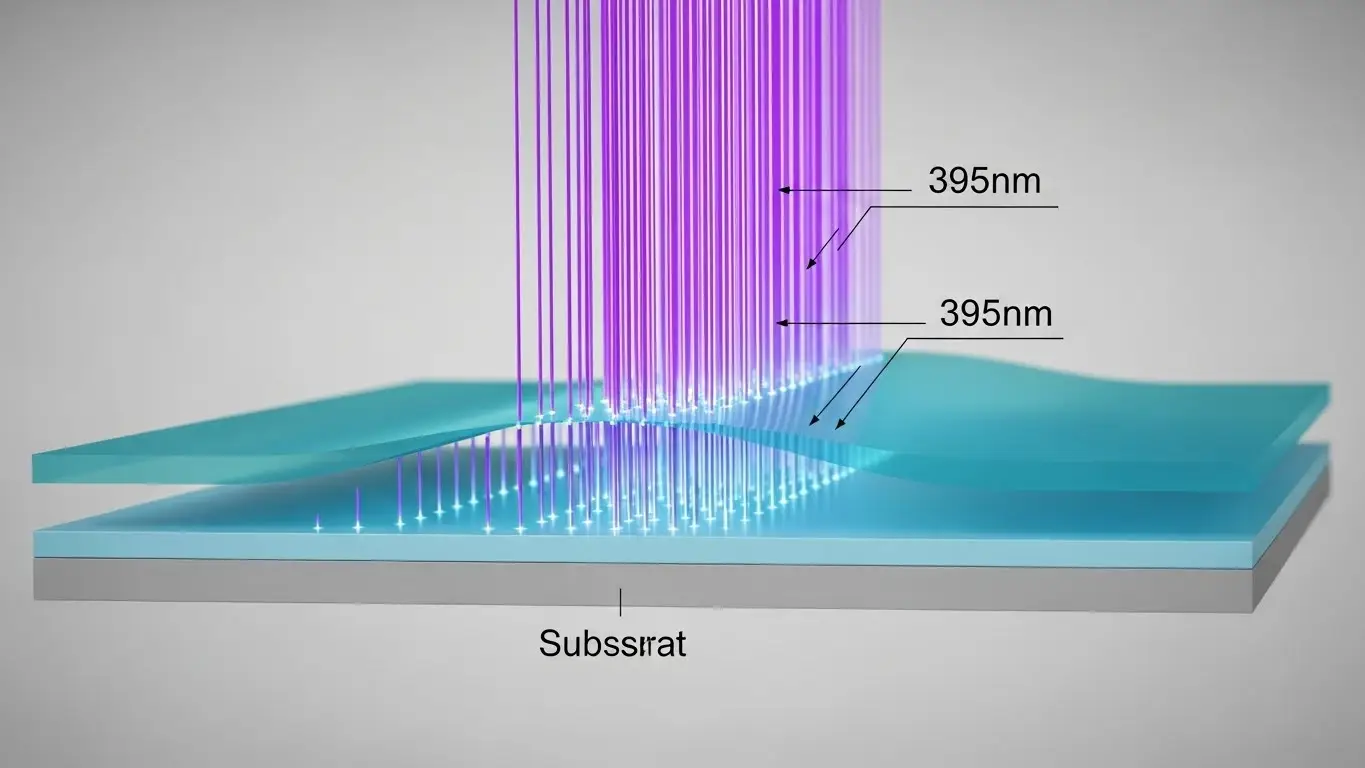

UV intensity, measured in watts per square centimeter ($W/cm^2$), indicates the instantaneous energy delivered to a surface and plays a key role in determining cure speed and uniformity. This metric, often called irradiance, tells you how "bright" the UV light is at a specific working distance from the lamp head.

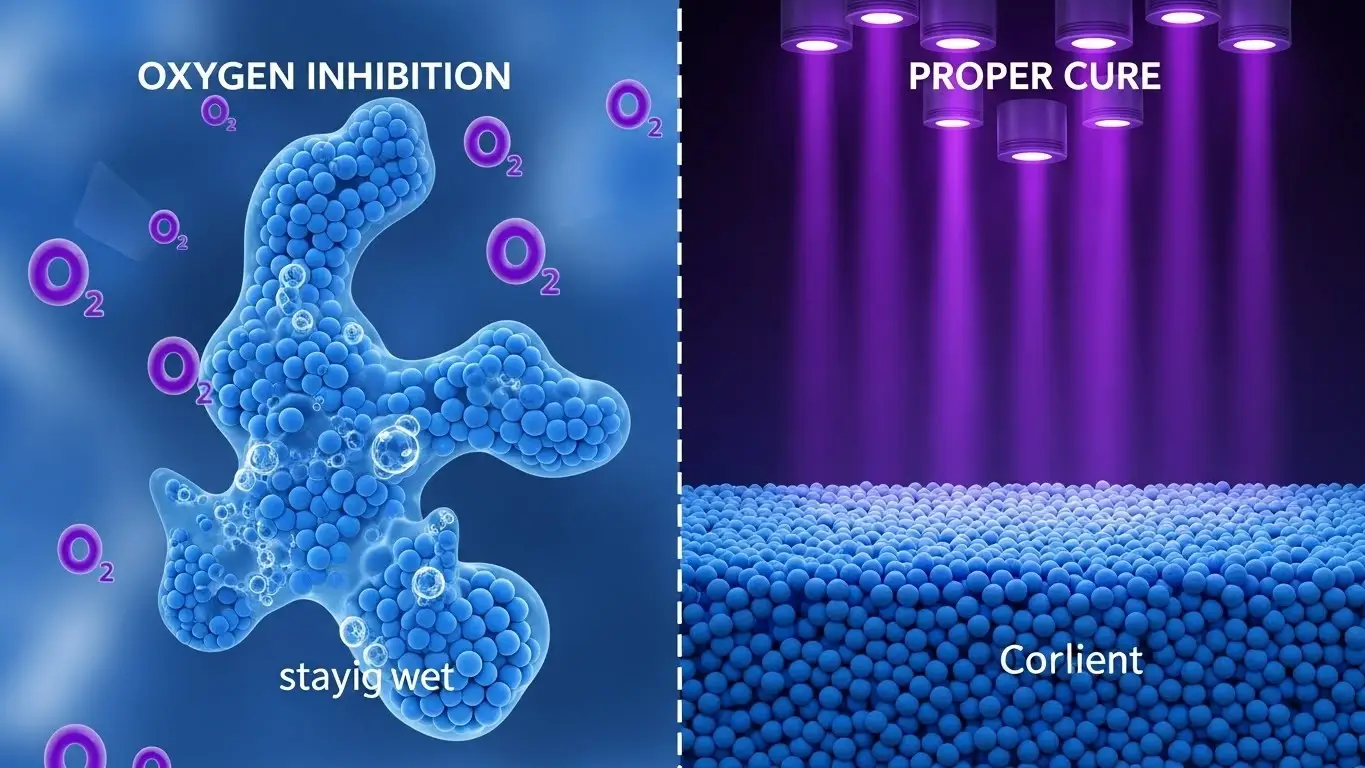

High intensity is required to overcome chemical inhibitions and ensure that the polymerization reaction starts immediately. You must distinguish this from "dose" or "energy density," which is the total amount of energy ($J/cm^2$) delivered over a period of time. While intensity triggers the cure, the dose ensures the reaction is completed through the entire thickness of your material.

Why Is Cooling Important in UV LED Systems?

Cooling is critical in UV LED curing systems because effective thermal management prevents overheating, supports stable output, and extends LED longevity. You will notice that as LED diodes get hotter, their light output efficiency drops and their peak wavelength can shift, potentially leading to incomplete cures.

Consistent cooling ensures that the diodes operate within their optimal temperature window, maintaining a steady irradiance level throughout a long production shift. Whether a system uses forced air or liquid chillers, the goal is to move heat away from the semiconductor junctions to prevent premature hardware failure and process drift.

How Do System Footprint and Form Factor Influence Selection?

Footprint and form factor describe the physical size and layout of a UV LED curing system and affect how easily it integrates into a production line or workspace. You must consider the dimensions of the lamp head and the power supply unit (PSU) to ensure they fit within your existing machine enclosures. A compact form factor is essential for applications with limited space, such as robotic arm mounting or narrow-web printing presses. Modular designs allow you to daisy-chain multiple lamp heads together, providing the flexibility to scale your curing area as your production requirements grow.

Power, intensity, cooling, and footprint are interrelated system attributes where higher power and intensity typically increase cooling needs and may affect footprint and integration. If you specify a system with extreme irradiance for a high-speed line, you will likely require a larger cooling system, such as a water chiller, which adds to the overall facility footprint.

Conversely, an air-cooled system might have a smaller total footprint but could be limited in its maximum intensity output to prevent thermal damage. Balancing these four specifications is the key to selecting a system that provides the necessary curing energy without exceeding your physical or environmental constraints.

What Practical Considerations Should You Use When Comparing UV LED Systems?

Practical comparisons of UV LED curing systems involve evaluating power and intensity in the context of material requirements, cooling strategy, and physical constraints. You should not compare systems based on a single "peak" number, but rather on how they perform under your specific operating conditions.

- Operational Intensity: Measure the irradiance at your actual working distance, not just at the lamp window.

- Thermal Stability: Evaluate how much the light output drops after the lamp has reached a steady operating temperature.

- Integration Ease: Check if the lamp head connectors and cable lengths suit your conveyor or robotic layout.

- Maintenance Requirements: Consider the accessibility of air filters or the complexity of maintaining a water-cooling loop.

- Total Cost of Ownership: Weigh the initial price against long-term energy savings and the expected 20,000+ hour lifespan of the LEDs.

What Are Common Misconceptions About UV LED Curing Specs?

Common misconceptions about UV LED curing specs include overemphasizing single numbers like power rating without considering intensity distribution and thermal management. You might assume that a "20-watt" lamp always cures better than a "10-watt" lamp, but if the 20-watt unit has poor optics, it may deliver less usable energy to your part. Another myth is that LED systems produce "no heat"; while they lack infrared radiation, the diodes themselves generate significant internal heat that must be managed to prevent output decay. Finally, many users confuse peak irradiance with total dose, leading to processes that are "tacky" on top or liquid underneath because the conveyor speed was not matched to the lamp’s output.

What Are the Key Takeaways on UV LED Curing System Specifications?

Successfully specifying a UV LED system requires an integrated understanding of how electrical power, light intensity, and thermal management work together. You get the best results when you prioritize the technical alignment between these specs and your specific material and throughput needs.

- Intensity ($W/cm^2$) triggers the cure; Dose ($J/cm^2$) completes it.

- Effective cooling is the only way to ensure stable light output and long diode life.

- The system's physical footprint must be balanced against its intensity and cooling requirements.

- Always validate system performance at your actual production working distance and speed.

How Do Air-Cooled and Water-Cooled UV LED Systems Compare?

Choosing between cooling methods impacts your system's intensity ceiling and facility requirements. You can read a detailed comparison of air-cooled vs water-cooled UV LED systems to see which fits your maintenance capabilities and production environment.

What Should You Know About Water-Cooled UV LED Curing Systems?

For high-intensity applications, liquid cooling is often necessary. Explore the design and benefits of a water-cooled UV LED curing system to understand the plumbing and chiller needs for your line.

What Should You Know About Air-Cooled UV LED Curing Lights?

If you need a simpler, more compact setup, air cooling might be the answer. Check our guide on air-cooled UV LED curing lights to learn about their typical use cases and integration advantages.

How Is UV LED Intensity Defined and Why It Matters?

Understanding the difference between irradiance and total energy is vital for process control. You can find a technical breakdown of UV LED curing intensity to help you calibrate your measurement tools and standards.

What Is UV LED Dose and How Is It Calculated?

Dose is the most critical factor for ensuring a complete through-cure. Use our resources for UV LED curing dose calculation to match your conveyor speed precisely to your lamp's output.

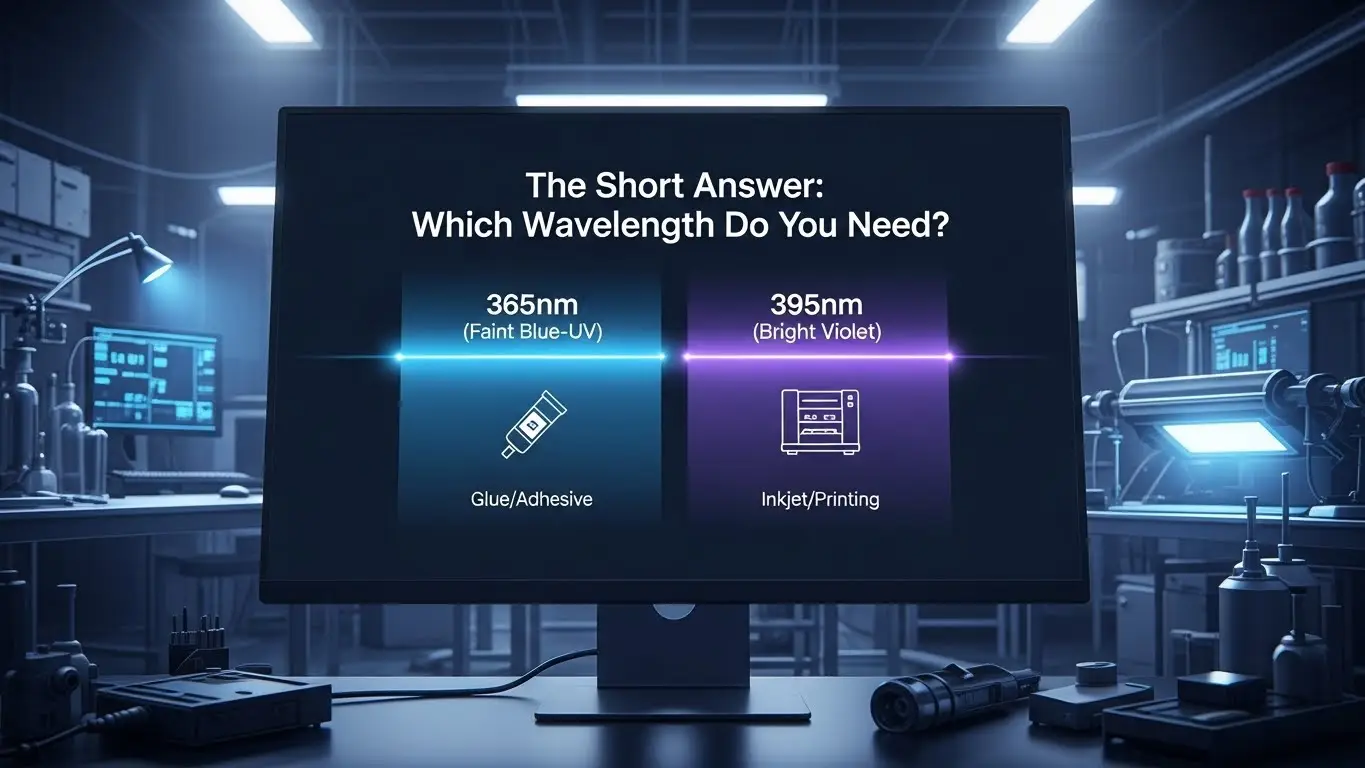

How Does Wavelength Affect Cure Depth and Uniformity?

System specs like intensity interact directly with the light's frequency. Review how UV LED wavelength affects cure depth to ensure your power is being delivered at the right frequency for your material.

How Does Lamp Temperature Relate to System Performance?

Thermal drift can ruin a perfectly calibrated process. Learn about the relationship between lamp temperature and UV output to see why monitoring your cooling system is essential for quality.

What Should You Know About System Maintenance for UV LED Curing Light?

Even solid-state systems require some care to stay within spec. Read about UV LED curing system maintenance to keep your lenses clean and your cooling systems running at peak efficiency.

Final Thoughts

Selecting a UV LED curing system is a process of balancing conflicting technical needs to find the "sweet spot" for your manufacturing line. While high intensity and power are attractive, they are only effective if supported by robust cooling and a form factor that allows for proper integration.

By focusing on how these specifications interact in a real-world production environment, you can build a curing process that is both high-performing and incredibly reliable. Your goal is to move beyond the numbers on a data sheet and understand how the system's specs will behave under the stress of a full production shift.