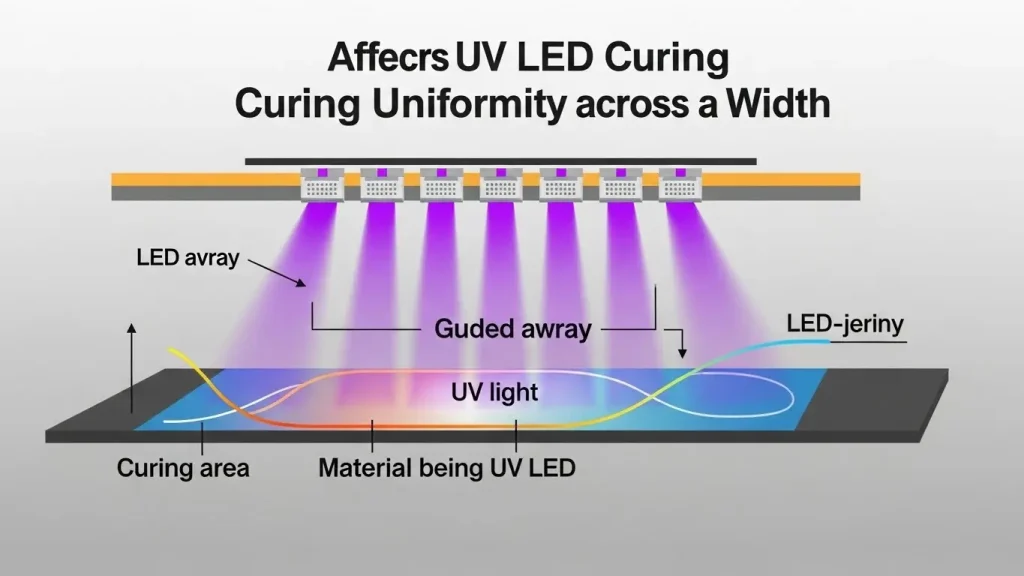

What Affects UV LED Curing Uniformity Across the Width?

In high-speed industrial manufacturing, achieving a consistent finish across the entire surface of a substrate is a critical quality requirement. Whether you are curing wide-format graphics or long electronic assemblies, the energy delivered at the far left must match the energy at the far right.

This guide examines the technical factors that influence UV LED curing uniformity across the width and how these variables impact your final product. By understanding the relationship between LED array design and process control, you can eliminate "soft spots" and ensure that every millimeter of your material reaches its intended structural strength.

What Does Uniformity Mean in UV LED Curing Across the Width?

Curing uniformity across the width refers to how evenly UV energy is delivered from one side of the curing field to the other, with consistent intensity and dose. It is a spatial measurement that ensures the photochemical reaction progresses at the same rate across the entire substrate. Without uniformity, you may experience variations in surface hardness or adhesion, leading to potential product failures in areas that received less energy.

How Does LED Module Arrangement Affect Uniformity?

The arrangement and spacing of individual LED modules directly influence uniformity because uneven overlap or gaps can create hot and cold spots across the width. If the internal diodes are placed too far apart, the intensity dips in the "valleys" between the chips, resulting in an inconsistent energy profile. High-performance systems use staggered or tightly packed arrays to ensure that the light from adjacent modules blends seamlessly at the working distance.

Why Does Intensity Distribution Matter for Uniformity?

Uniformity depends on even intensity distribution because variations in energy per unit area result in unequal dose and inconsistent cure across the part. If the center of your lamp head is significantly brighter than the edges, the peripheries of your substrate will remain tacky while the middle is fully hardened. Maintaining a flat intensity profile across the entire curing window is essential for achieving predictable results in high-speed, wide-web applications.

What Role Do Thermal and Temperature Effects Play in Uniformity?

Thermal effects such as lamp temperature and cooling strategy influence uniformity because uneven heating can change LED output and energy distribution across the width. Because LED efficiency decreases as the junction temperature rises, an array with poor thermal management may exhibit "output decay" in its hottest sections. Consistent cooling across the entire array is necessary to prevent these thermal gradients from creating localized drops in UV intensity.

How Does System Design and Power Scaling Influence Uniformity?

Overall system design and how power is scaled in larger curing systems affect uniformity because broader curing widths require careful balance of output across modules. As the curing field grows, maintaining a consistent electrical drive current to every diode bank becomes more complex. Modular system architectures are often used to provide independent power control to different sections of the width, ensuring that the energy profile remains stable over large areas.

What Practical Considerations Can Improve Uniformity?

Improving uniformity typically involves optimizing module alignment, managing intensity balance, controlling operating temperature, and ensuring maintenance keeps the system predictable. You can achieve a more stable process by following a structured verification routine:

- Regularly map the curing field using a multi-channel radiometer to detect intensity dips.

- Verify that the lamp head is perfectly parallel to the conveyor or substrate surface.

- Clean individual LED lenses to ensure that dust or overspray is not blocking the light.

- Monitor the cooling system to ensure that temperature remains uniform across the entire array.

What Are Common Misconceptions About Uniformity Across the Width?

Common misconceptions about uniformity include assuming that simply increasing power or speed alone will fix uneven cure without addressing spatial intensity and thermal balance. More power often just intensifies existing "hot spots," potentially over-curing some areas while others still remain under the required threshold. Another myth is that "wider lamps are always more uniform," whereas the complexity of maintaining a flat profile actually increases as the curing field expands.

What Are the Key Takeaways on UV LED Curing Uniformity Across the Width?

Achieving uniform results across a wide curing field is a technical product of physical array design, stable thermal management, and precise process verification. Consistent results are only possible when the energy profile is flat across the entire substrate width.

- Uniformity ensures consistent surface hardness and bond strength across the part.

- Module spacing and overlap are the primary drivers of the spatial energy profile.

- Stable thermal management prevents localized output decay.

- Regular radiometer mapping is the only way to verify that your system is meeting spec.

How Do System Specifications Influence Uniformity in UV LED Curing?

System architecture dictates the baseline energy distribution. You can learn how broader specs relate to even delivery in our guide on UV LED curing system specs.

How Does Lamp Temperature Affect Output Consistency Across the Width?

Thermal gradients can cause the light output to shift or weaken. Explore the relationship between lamp temperature and uniformity for more technical details.

How Does System Maintenance Impact Uniformity?

Dirt or aging can create uneven energy pockets across your lamp head. Follow our maintenance guide to keep your output consistent.

How Do Water-Cooled Systems Influence Uniformity?

Liquid cooling provides the most stable thermal environment for wide arrays. Check out the benefits of a water-cooled UV LED curing system for high-precision tasks.

How Do Air-Cooled UV LED Systems Behave in Terms of Uniformity?

Air-cooled units are more susceptible to internal temperature variations. Read about air-cooled UV LED curing lights to see how they handle heat distribution.

What Are the Differences Between Air-Cooled vs Water-Cooled Systems for Uniformity?

The cooling method you choose directly impacts your energy stability. See a side-by-side look at air-cooled vs water-cooled UV LED strategies.

What Defines a High-Power UV LED Curing System in Relation to Uniformity?

High-power requirements make maintaining uniformity even more challenging. Learn about high-power UV LED curing systems and their design considerations.

How Does Intensity Distribution Affect Uniformity Across the Width?

The spatial profile of your lamp is the most important variable for even curing. Review how UV LED intensity is measured and balanced.

Final Thoughts

Finalizing your approach to uniformity is a step toward eliminating the hidden defects that plague high-volume production lines. While it is easy to focus on peak intensity, the true indicator of a reliable process is how well that intensity is maintained across the entire width of your product. By prioritizing array design and robust cooling, you can build a curing cycle that remains stable even as your production speeds increase. The best curing system is one where the energy delivery is so consistent that the location of the part on the conveyor becomes irrelevant to its final quality.