UV LED Modules – Engineered for Integration. Optimized for Results.

Designed with OEMs in mind, these UV modules ensure fast curing, easy installation, and long service life, helping you accelerate innovation and reduce costs.

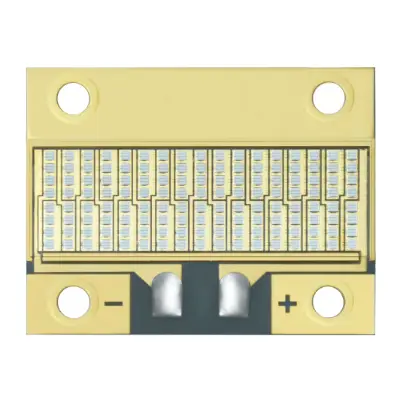

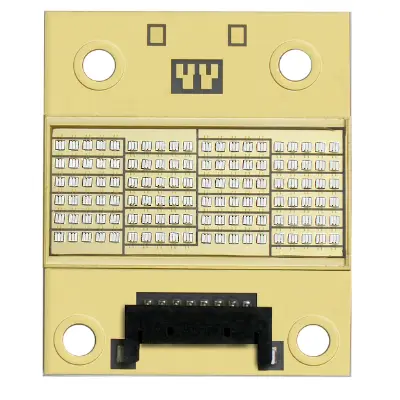

UV LED modules are high-performance ultraviolet light source components that integrate UV-emitting chips. Equipped with premium UV LED chips that provide stable, high intensity UV radiation suitable for industrial-grade applications enables such high power output. Along with those lasers guided by cameras combined with still cameras allow real time inspection.

Technical Specifications (Customizable):

-

Emission Wavelength: 365 / 385 / 395 / 405 nm

-

LED Power: 1W–100W+ (based on configuration)

-

Voltage Range: DC 3V–48V (depending on model)

-

Base Type: Aluminum substrate / COB / SMD module

-

Lifespan: >20,000 hours

-

Size & Interface: Custom dimensions

Collaborate with us to integrate advanced UV LED modules that drive precision, performance, and innovation in your systems.

Features:

-

Extreme Power Output Flexibility: At 365nm, 385nm, 395nm, or 405nm, seven different configurations can be used incurring high energy efficiency for industrial-grade applications.

-

Competitive Advanced Modular Design: OEMs and system integrators benefit directly from the compact and flexible modules that can be stacked or further expanded.

-

Effective Heat Loss Management: Utilizing aluminum substrates or graphite thermal pads facilitates appropriate functioning and increases longevity even at high power levels.

-

Energy Saving and Environment Friendly: CAPEX UV LED's provide instant start-up, longer life, and generate no ozone or harmful substances compared to traditional mercury lamps.

Applications:

-

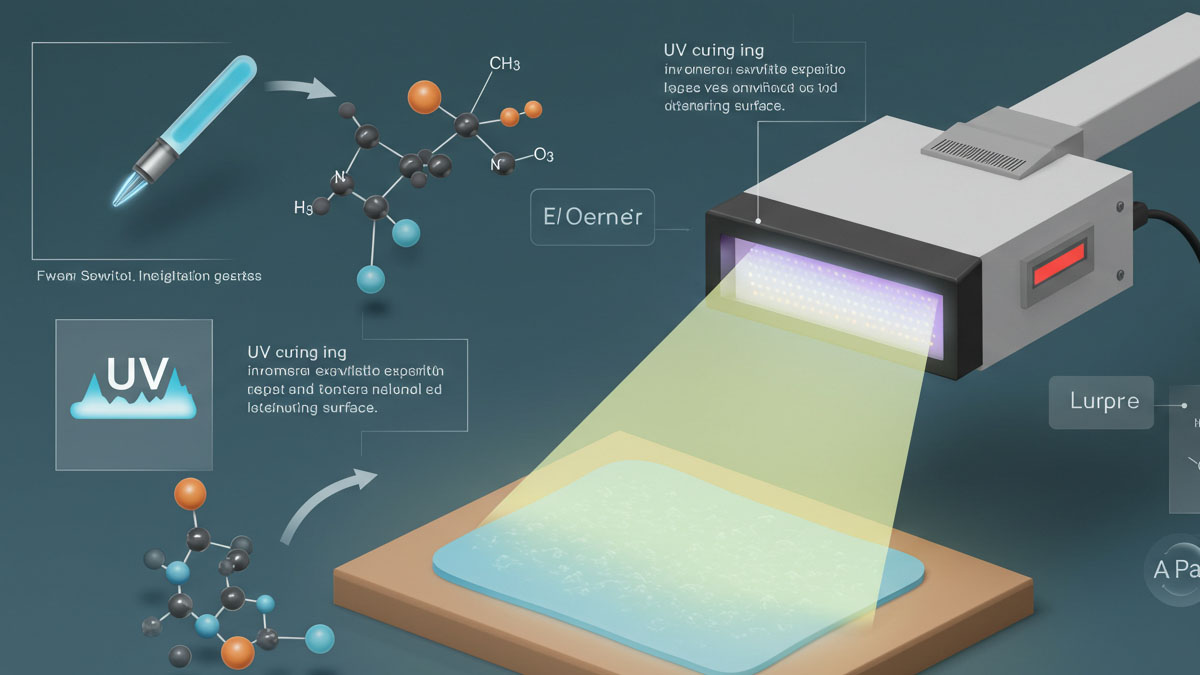

Adhesives, inks, and coatings UV curing

-

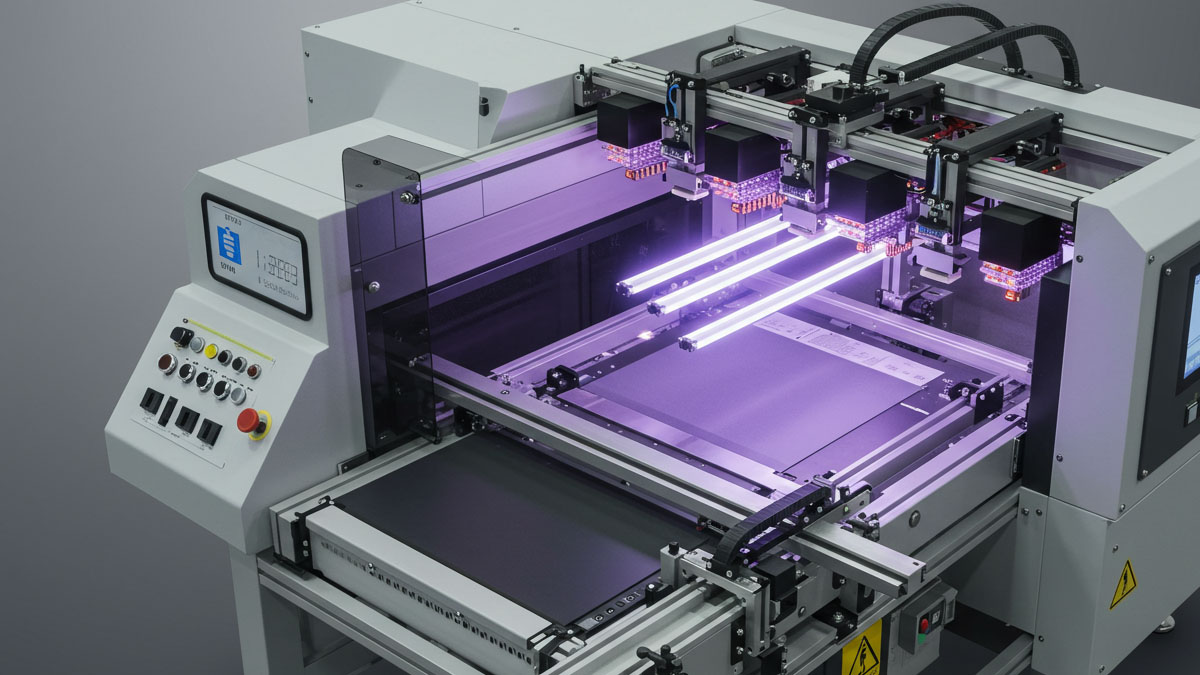

Photolithography, PCB exposure and printing

-

Sterilization and disinfection using UV light

-

Detection of fluorescence and anti-counterfeit marking and labeling.

-

Light source systems for scientific research labs and other systems.

How to Choose the Right UV LED Module

1. Choose the application of the module.

Identify the specific purpose for using the module as follows:

- For curing drugs – adhesives, inks, and coatings

- Disinfection and sterilization – water, air, and medical

- Excitation of fluorescence for diagnostics and sensors for laboratories and NDT.

- Printing or therapy via UV radiation

- Industrial visual inspection systems

Different applications may need different cooling methods, intensities, and even wavelengths.

2. Select the appropriate wavelength.

- Wavelengths 265 – 280 nm will be effective for sterilization and tissue disinfection while having germicidal impact.

- For therapeutic use, 300 – 320 nm will suffice for UVB as well as certain biochemical applications.

- Wavelength of 365nm is effective for UV curing and reclamation, inspections, and fluorescence detection and is classified under UVA.

- Between 395 and 405 nm can be used for cost effective general illumination and curing purposes.

Always ensure to your choice is based on your target photoreactive or fluorescence material.

3. Verification of Output Power and Intensity

Evaluated in mW/cm² or total radiant flux (in mW or W).

The curing time is directly proportional to the power output, as is the strength of the fluorescence observed.

Decide if you require:

- Spot modules (focused beam)

- Flood modules (wide area coverage)

- Linear modules (found in conveyors or lines)

4. Assessment of Thermal Management

UV LEDs generate significant heat. Look for:

- Integrated fan or water-cooled modules

- Low thermal resistance (aluminum MCPCB or ceramic)

These modules will suffer degraded performance and a reduced lifespan due to poor heat dissipation.

5. Compatibility with Power Supply and Drivers

- Check for the correct voltage and current requirements such as 12V or 24V constant current/voltage.

- For each module, ensure that the power supply is aligned with the specifications.

- Some modules have integrated drivers while others need external one(s) to be fully functional.

6. Configuration and Installation

- The equipment or fixture should accommodate the size and shape (round, strip, square).

- Some modules are equipped as plug-and-play while the others require PCB mounting.

- Consider the IP rating where the equipment is placed if it’s dusty or humid.

7. Service life and Dependability

- A UV lamp should last 10,000 to 50,000 hours.

- Quality modules provide LM-80 and/or MTTF results.

- Find the ESD protection of the device; it can be crucial in sensitive environments.

8. Additional functionalities

- Optics: shape the beam using Lens, Collimator, or reflector

- Ability to dim and PWM control.

- Calibration of the wavelength/ binning or grouping of the same wavelengths.

- Sensors with status indicators or reporting functions.

2. Choose the Right Wavelength

| Wavelength | Application |

|---|---|

| 265–280 nm (UV-C) | Sterilization, disinfection, germicidal effects |

| 300–320 nm (UV-B) | Phototherapy, biochemical applications |

| 365 nm (UV-A) | UV curing, inspection, fluorescence detection |

| 395–405 nm | General lighting, cost-effective curing |

⚠️ Choose based on the photo-reactive material or fluorescence target you're working with.

3. Check Output Power & Intensity

-

Measured in mW/cm² or total radiant flux (mW or W)

-

Higher power = faster curing or stronger fluorescence

-

Consider whether you need:

-

Spot modules (focused beam)

-

Flood modules (large-area coverage)

-

Linear modules (used in conveyors or lines)

-

4. Evaluate Thermal Management

UV LEDs generate significant heat. Look for:

-

Built-in heat sinks or active cooling (fan or water-cooled modules)

-

Low thermal resistance substrates (e.g., aluminum MCPCB or ceramic)

🧊 Poor thermal control will reduce lifespan and performance.

5. Power Supply & Driver Compatibility

-

Confirm voltage and current requirements (e.g., 12V, 24V constant current or constant voltage)

-

Make sure your power supply matches the module specs

-

Some modules include integrated drivers; others require external ones

6. Form Factor and Mounting

-

Size and shape (e.g., round, square, strip) should fit your equipment or fixture

-

Some modules are PCB-mounted, while others are enclosed for plug-and-play

-

Consider IP rating if used in humid or dusty environments

7. Lifespan & Reliability

-

Look for rated lifespans of 10,000–50,000 hours

-

High-quality modules will list LM-80 test results or MTTF

-

Check if the module is ESD protected (especially important in sensitive environments)

8. Optional Features

-

Optics: Lens, reflector, or collimator to shape the beam

-

Dimming or PWM control

-

Wavelength calibration or binning

-

Integrated sensors or status indicators

🧪 Summary Checklist

| Feature | Recommendation |

|---|---|

| Wavelength | 265–280 nm (sterilization), 365 nm (curing/inspection) |

| UV Output Power | Sufficient for your application's curing/sensing needs |

| Thermal Management | Active cooling or efficient heat sink |

| Electrical Input | Match voltage/current, choose reliable driver |

| Mounting/Form Factor | Fit your equipment or product integration |

| Lifespan | 10,000+ hours with proven reliability |

| Optional Features | Optics, dimming, waterproofing as needed |