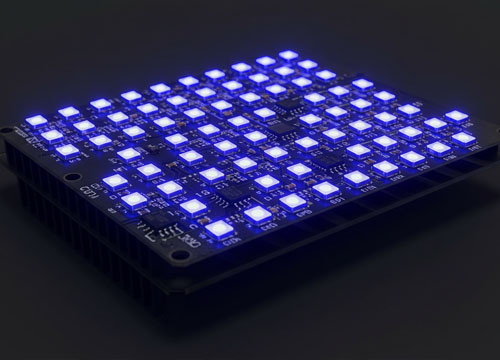

Array LED UV Modules- Engineered for Coverage. Designed for Control

With precision optics and multi-LED arrays, these modules ensure uniform UV output and wavelength stability—supporting demanding industrial workflows.

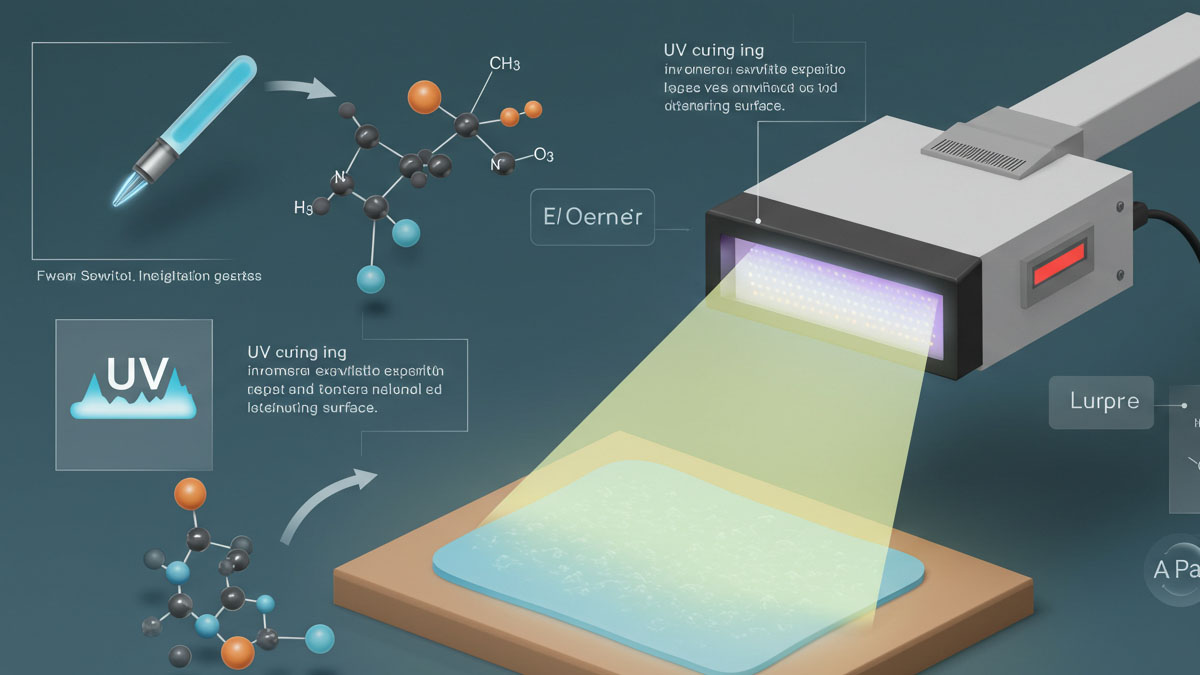

Array LED UV modules incorporate several high-power UV LEDs configured in a regular grid, providing large-area ultraviolet output with high intensity. These modules are suitable for industrial curing, printing, coating drying, sterilizing, semiconductor photolithography, and can be enabled with custom emission wavelengths of 365nm, 385nm, 395nm, 405nm, or tailored to specific dimensions, power, and interface requirements for diverse automated systems and production lines.

Technical Specifications

-

Wavelengths: 365 / 385 / 395 / 405 nm

-

LED Count: 4 to 400+ LEDs

-

Power Range: 10W – 1000W+

-

Input Voltage: DC 12V–48V / AC 100–240V

-

On/Off switch / Dimming / Communication control

-

Cooling Method: Air-cooled or water-cooled

-

Lifespan: >20,000 hours

-

Module Size: Customizable to application requirements

Partner with us to develop high-performance Array LED UV Modules that enable precision, speed, and scalable integration for your applications

Features

High Blanking Ratio: Very low light spill outside the illuminated area ensures sharp edges on cured exposure.

Multi-Wavelength Options: Available in 365nm, 385nm, 395nm, 405nm, or mixed designed for specific response curves of materials to be processed.

Modular and Scalable Design: Supports daisy-chaining or side-by-side installation for user-defined illumination rectangles.

Smart Control Interface: Supports PWM dimming, communication via RS485/RS232, and PLC interfacing for automated systems in industrial applications.

Efficient Cooling Systems: Actively cooled via air or water for dependable long-term use.

Typical Applications:

-

-

Quick curing of UV inks, coatings, and adhesives

-

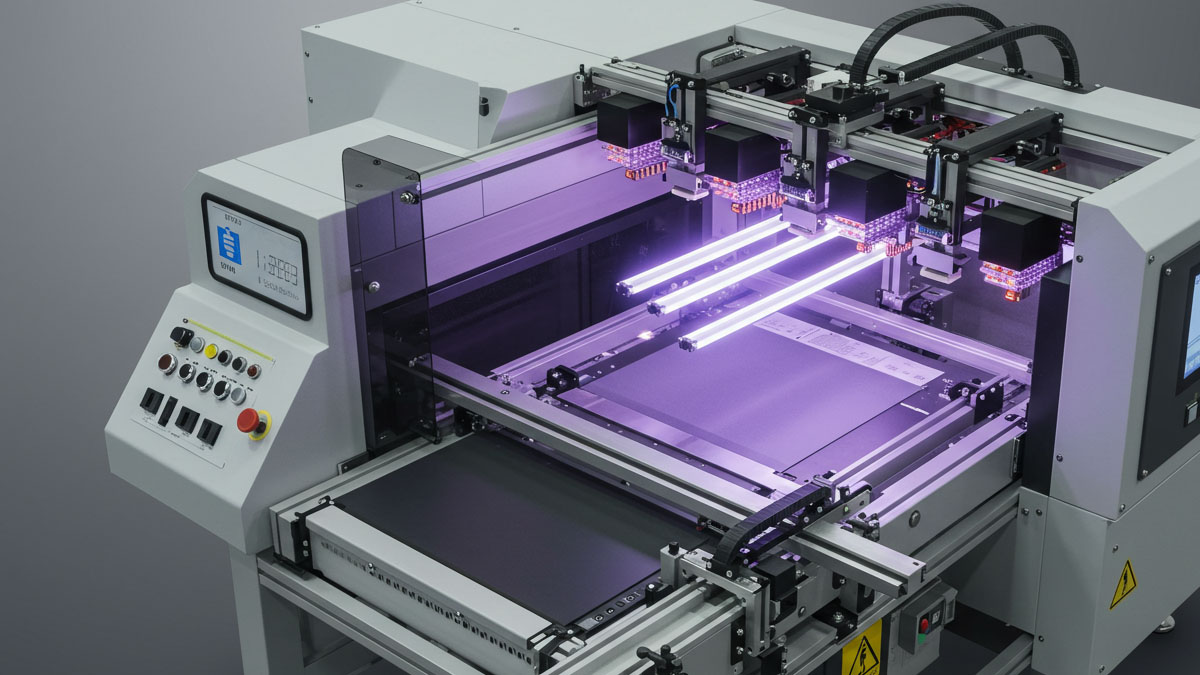

PCB exposure and drying processes

-

Shallow and deep photolithography as well as semiconductor processing

-

Medical surface sterilization and equipment disinfection

-

UV source for flexographic, screen, or inkjet printing

-

How to Choose the Right Array LED UV Module

-

Define the Application

Determine the most suitable use case from the following:

-

UV Curing: inks, coatings, adhesives in industrial and commercial printing, PCB coating, and packaging.

-

Disinfection/Sterilization: air, water, or surfaces cleansing.

-

Fluorescence Excitation: biological imaging or quality control inspection.

-

Photolithography: semiconductor or PCB exposure.

-

Machine vision/sorting systems.

All these processes have different requirements for wavelength selection, power and cooling systems, and…

-

The Right Wavelength

| Wavelength | Ideal For |

|---|---|

| 265–280 nm (UV-C) | Germicidal / Disinfection (air, water, surfaces) |

| 300–320 nm (UV-B) | Phototherapy, lab use |

| 365 nm (UV-A) | UV curing, industrial inspection, NDT |

| 395–405 nm | Low-cost curing, scorpion/stain detection |

365 nm is the most common for industrial curing and precision inspection.

Only UV-C 265–280 nm lamps are permitted for sterilization.

-

Measurement of Total Radiant Power as an Output

Optical power settings can be set to high (W or mW/cm²) to enable quicker and deeper curing along with stronger fluorescence.

Make sure to check for uniform intensity across the array to confirm consistent performance.

For curing, typical targets are:

-

Greater than 1,000 mW/cm² for high-speed production lines for laser-processed products.

-

300 – 800 mW/cm² for general or slower curing applications.

-

Spatial Characteristics and Geometric Configuration of the Radiation Source

-

Linear Arrays: Suitable for curing by conveyor and for strip inspection.

-

Matrix Arrays: Suitable for broad area curing and panel exposure.

Make certain that the active emitting area conforms with your part or inspection surface.

If scalability is required, consider modular stacking.

-

Thermal Management System

-

Passive cooling is applicable for low-power modules (limited range).

-

Active air-cooled is common in mid-power applications.

-

Water cooled is best for high intensity continuous duty cycle operation.

Look for aluminum MCPCB, heat sinks or components with integrated fans.

-

Electrical Interface

Confirm:

-

Input voltage (12V, 24V, or 48V DC)

-

Current draw requirements

-

Need for constant current driver

-

Included drivers versus need for external control units

-

Control and Integration

Look for:

-

PWM dimming or other forms of dimming control

-

Trigger/sync inputs for automation

-

Digital interfaces like RS485, CAN or MODBUS in higher-level systems

-

Product Robustness and Lifetime

High output power UV LEDs from reputable manufacturers should have:

-

10,000–50,000 hours lifespan

-

LM-80 testing or MTTF data

-

Dust, humidity, or water resistant enclosures with an IP rating.

-

Additional Options

Changeable optics such as:

-

Lenses, diffusers, reflectors

-

UV-pass filters for blocking non-target wavelengths

-

Calibration for uniformity or spectral binning over-calibration

-

Protection against overheating and diagnostics on-board

Summary Checklist

| Feature | Recommendation |

|---|---|

| Wavelength | 265–280 nm (sterilization), 365 nm (curing/inspection) |

| Output Power | ≥300–1000 mW/cm² for curing or high visibility |

| Cooling System | Active (air/water) for medium to high-power use |

| Array Type | Linear (for lines) or Matrix (for large areas) |

| Input/Driver | Match voltage and current specs; CC driver preferred |

| Control Interface | PWM, digital control, or trigger sync |

| Durability | Long lifespan, IP-rated if needed |

| Integration | Optics, mounting brackets, smart features |