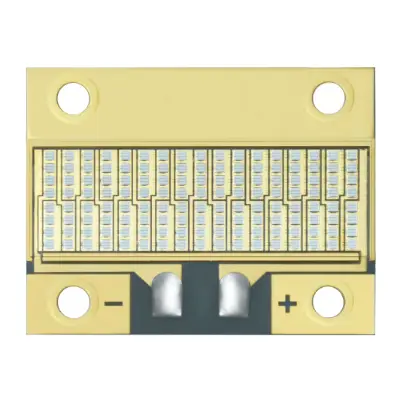

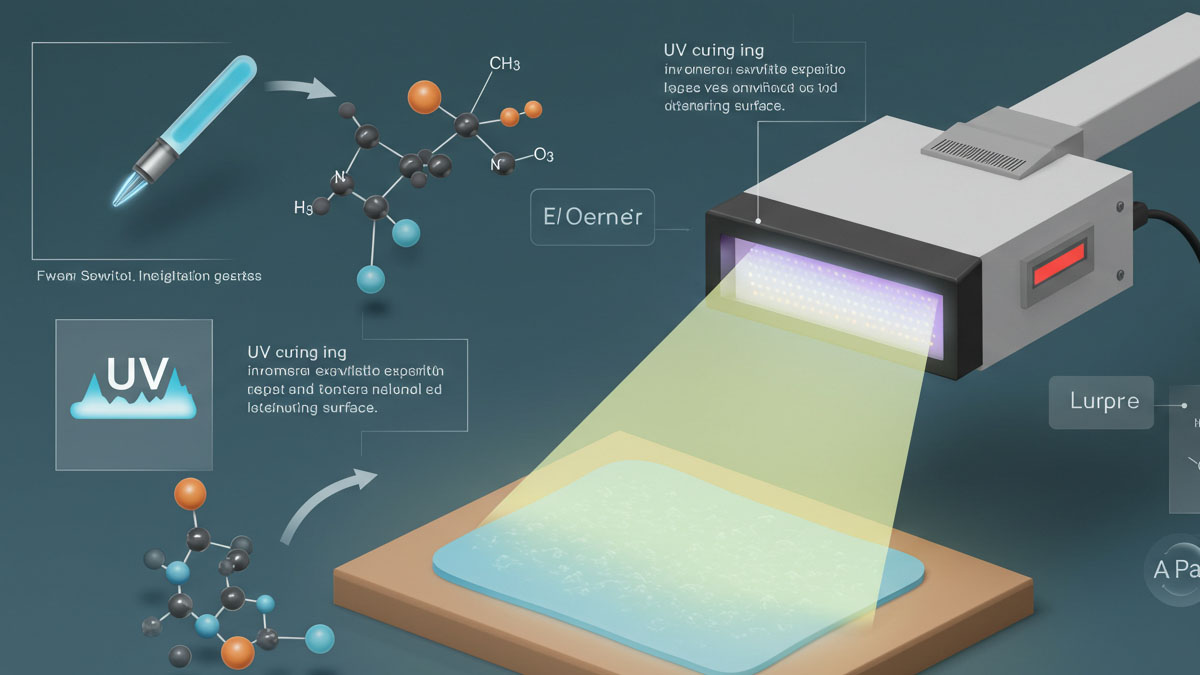

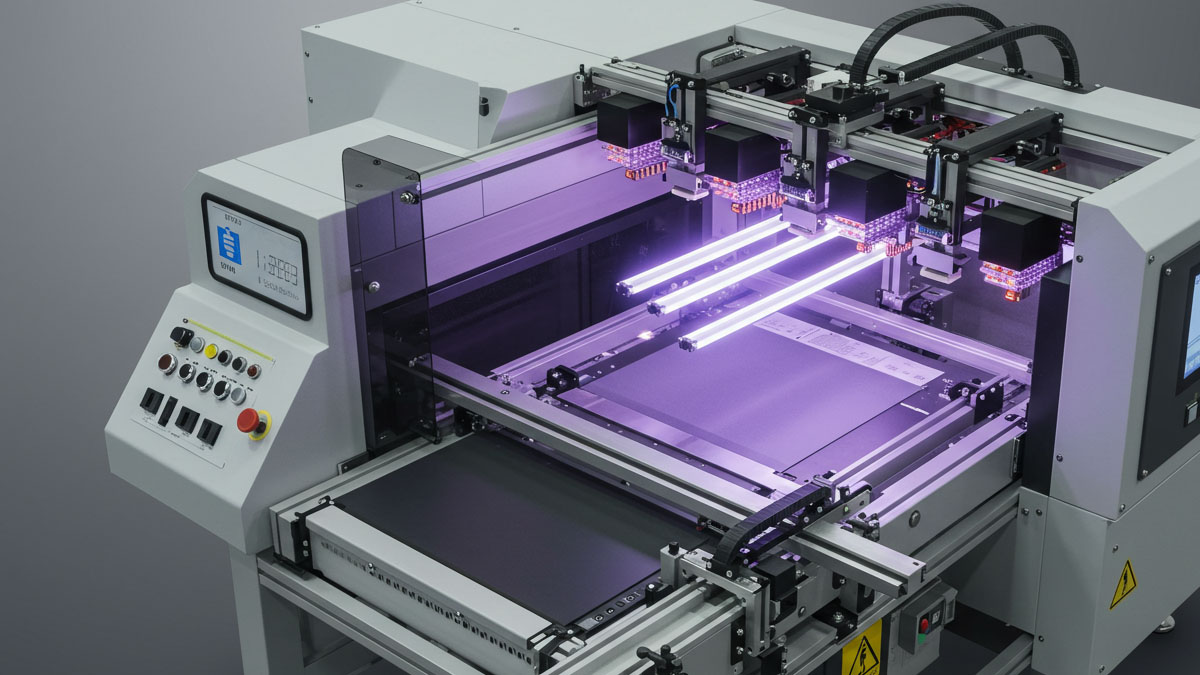

COB UV modules are applicable in over forty industries including but not limited to, curing of adhesives, inks, Ph coatings, photolithography, sterilization, and fluorescence detection. They can be used in labs or workshops needing specific industrial conditions since customized emission wavelengths of 365nm, 385nm, 395nm and 405nm are supported.

Key Features:

- High Power Density:

- Concentrating coverage boosts radiative efficiency of UV C modules, enabling faster curing or sterilizing even in limited areas.

- Thermally Superior:

- The direct mounting of LED chips on thermally conductive substrates such as aluminum or ceramic allows heat to be shed optimally, thus increasing the modules lifespan.

- Illumination Uniformity:

- Critical for advanced curing and inspection processes to ensure smooth, even UV radiation with minimized hotspots.

- Multiple Configurable Geometries:

- These include round and square, rectangular as well as other shapes which fit the fixture or installation requirements.

- Operationally Unchanged:

- Environmental and cost impacts are reduced due to low power consumption and instant-on operations.

Typical Applications:

- Curing of coatings, inks, and adhesives using ultraviolet (UV) lasers within portable or compact devices.

- Performing sterilization and disinfection on medical or laboratory equipment.

- Photolithographic techniques using tight spatial and temporal dimensional apertures.

- Fluorescence processes for diagnostics and quality assessments.

- Industrial inspection systems which are compact.

How to Select the Best COB UV Modules?

-

Fit To Application:

Assess if the application utilizes high-peak irradiance handheld UV devices requiring high spatial uniformity and precision for measurement. -

Selection of Wavelength:

Based on the curing chemistry, sterilization criteria, and expected response from fluorescence, select from 365nm, 385nm, 395nm or 405nm. -

Power and Intensity:

Confirm outputs in mW/cm² meets your process throughput and precision depth requirements. -

Design based on Heat Transfer:

Ensure the module utilizes advanced substrates and cooling designs for continuous or intermittent operation cycles demanding high thermal management. -

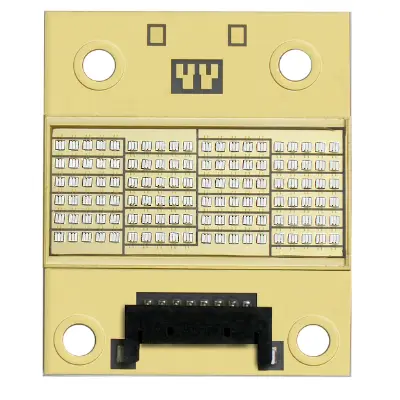

Electrical Compatibility:

Check rated voltage and current, integrated drivers, and if external drivers are needed. -

Mechanical Integration:

Consider IP ratings for environmental sealing and the dimensioning of the module for the intended equipment. -

Dependability:

Seek out pertinent to your operational parameters lifetime documentation, thermal cycle testing, and electrostatic discharge shielding micrometric filters. -

Further Specifications:

For increased flexibility regarding use, integration, and optimization, the opto-mechanical interfaces, feedback systems, and closed-loop control algorithms are customizable.