What is a UV LED Oven and how does it work?

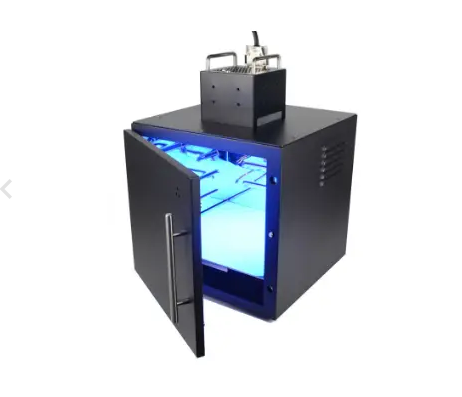

An ultraviolet curing system (also known as an LED UV curing oven or UV LED oven) is a highly developed ultraviolet curing system that applies semiconductor diodes to produce certain UV wavelengths, typically 365nm, 385nm, 395nm, and 405nm, to initiate the crosslinking process of the polymer. This reaction quickly hardens or cures materials with UV-reactive resins, producing strong and durable finishes.

Key Technical Components

UV LED Arrays: Intense-driven LED arrays that are designed to produce a uniform UV light.

Thermal Control System: This is a system that has closed-loop temperature regulation to achieve constant temperature during curing.

Digital Control Interface: Provides the options of fine-tuning the UV curing intensity, exposure time, and calibration of power density.

Cooling System: LED chip cooling technology makes sure that the cooling does not overheat the system, and the LED has a long lifespan.

Reflective Chamber Design: Geared towards the uniformity of optical power in the curing area.

This ultraviolet curing oven is driven by an LED, so it provides accuracy and predictability in all its processes- ideal in the application of UV LED curing, high-performance in both industries and laboratories.

The benefits of UV LED Curing Ovens

The benefits of the UV LED curing technology span all areas of industrial processing.

1. Instant, Fast Curing

The fast-curing UV LED oven is a process that provides almost immediate polymerization with the exposure of high-intensity ultraviolet rays and shortens the production cycle time to a considerable degree.

2. Environmentally-friendly and energy efficient

LED UV curing ovens also use low power and produce low heat in comparison to mercury-based systems. Their UV LED technology, which is energy-saving, facilitates sustainable operations with reduced carbon footprints.

3. Precision and Consistency

These ovens have real-time intensity control and UV irradiance control, which guarantees the output performance of each batch of UV on a consistent basis- important in high-precision bonding.

4. Longer LED Lifespan

The LED modules have a long lifetime of more than 20,000 hours and require minimal maintenance to maintain uninterrupted uptime, as well as provide maintenance-free curing technology.

5. Compact and Scalable Design

They are offered in 3 versions, as bench-top, portable, or multi-zone UV LED curing ovens, and can be easily installed in R&D laboratories as well as mass production lines to provide scalable UV curing options.

Applications of UV LED Ovens

The UV LED curing oven has a broad area of application and offers good performance of UV curing in different industrial and research setups.

Optical Components Manufacturing

With the use of the oven, optical things like lenses, prisms, filters, and fiber assemblies can be bonded, sealed, and coated. Even distribution of UV light means curing without thermal damage.

Adhesive Bonding

Adhesives UV LED ovens find application in electronics, automotive, and medical device assembly, where high adhesion and fast curing are important.

Coating applications in industries

The UV LED coating oven works best with automotive coatings, plastic finishes, and metallic finishes, and ensures perfect curing with increased durability of the surface.

Printing and Inks

UV LED ink ovens used in the printing industry allow immediate curing of the UV-reactive inks and enhance the quality of the print and speed of production.

PCB and Electronics Production

Electronic UV ovens are used to provide safe, low-temperature UV curing, which is necessary when using heat-sensitive components. PCB ovens are important in the microelectronics assembly process.

3D Printing and Resins

In 3D printing, resin curing by UV LED ovens creates a smooth and high-detailed, dimensionally stable component.

Medical Device Fabrication

In the case of medical-grade adhesives and coatings, UV LED curing chambers offer a contamination-free chamber in line with medical requirements.

UV LED Ovens in Laboratory Research

UV LED area curing lamps and curing ovens are essential in materials science and optical research, as well as in controlled experiments.

Their applications include curing glues, adhesives, and coating and electronic materials- increasing durability and reliability in prototypes.

Key Applications in Labs:

Performance Test: Test the behavior of materials under UV radiation and curing.

Reproducible Results: Have repeatability to validate the experiment.

Safe Environment: A clean and stable working environment that is free of any risks- a significant improvement of mercury UV systems.

Optics UV LED oven in laboratory materials investigation facilitates the accuracy of testing the adhesion strength, kinetics of polymers sensitive to UV, and reaction of photo switchable initiators to varied UV intensity.

Wavelength of UV LED and the science of curing

UV Wavelength Options

The common wavelengths of curing are:

- 365 nm - Deep penetration of thick coating.

- 385 nm - Adhesive balanced energy.

- 395 nm - high-speed curing standard.

- 405 nm - Photo-initiator compatibility is optimum.

Photoinitiators are activated by these wavelengths and cause polymerization and crosslinking reactions. This is an ultraviolet curing process that allows instant conversion of UV-reactive resins to solid polymers.

Curing speed and depth depend on the photopolymerization kinetics and energy dose measurement. The UV LED heat management system is able to avoid heat stress and preserve the integrity of the product.

Automation and Integration of Industry

UV LED ovens are used in intelligent manufacturing operations where automated production lines, robotics, and PLC systems are incorporated into the ongoing production process.

The automated UV LED curing machine guarantees:

- Uniform exposure

- Precise process timing

- Real-time UV power feedback

- Temperature stability

These intelligent UV LED curing systems are establishing a new standard in automation in the industry with the help of IoT-based monitoring and AI-assisted calibration.

Calibration and Maintenance

- With the right UV LED oven maintenance and calibration, one is guaranteed of long-term operation and safety.

- Check the intensity and uniformity of UV LEDs on a regular basis.

- Calibrate temperature using by built-in sensors.

- Maintain clean optical surfaces to maintain the same irradiance.

- Precision setting update control software.

- Maintenance-free UV LED oven model of UVNDT makes maintenance easy and maximizes productivity.

Conclusion

UV LED Oven is the leader of ultraviolet curing innovation, integrating efficiency, accuracy, and longevity. It is much better than the traditional methods of curing as it is fast-curing, has low heat output, and superior control systems. Since optical bonding and adhesive curing are now a practical solution, as well as the coatings and 3D printing, UV LED ovens can now be considered an indispensable tool of both modern industry and research laboratories. With the shift of industries into smart manufacturing and production based on eco-friendly processing, UV LED curing technology will stay at the top. In order to know more about the advanced curing solution or to seek specifications, please visit UVET - your reliable supplier of next-generation UV LED curing systems.