Water-Cooled UV LED Curing System: When You Need It

In high-demand industrial manufacturing, managing the heat generated by high-intensity light sources is a fundamental engineering challenge. While UV LEDs are more efficient than traditional mercury lamps, they still produce significant thermal energy that must be moved away from the semiconductor junctions to prevent performance drift.

This guide explores the technical requirements of a water-cooled UV LED curing system, identifying the specific production scenarios where liquid cooling becomes a necessity. By understanding how liquid thermal management supports consistent irradiance and long-term diode health, you can make a data-driven decision for your manufacturing line.

What Is a Water-Cooled UV LED Curing System?

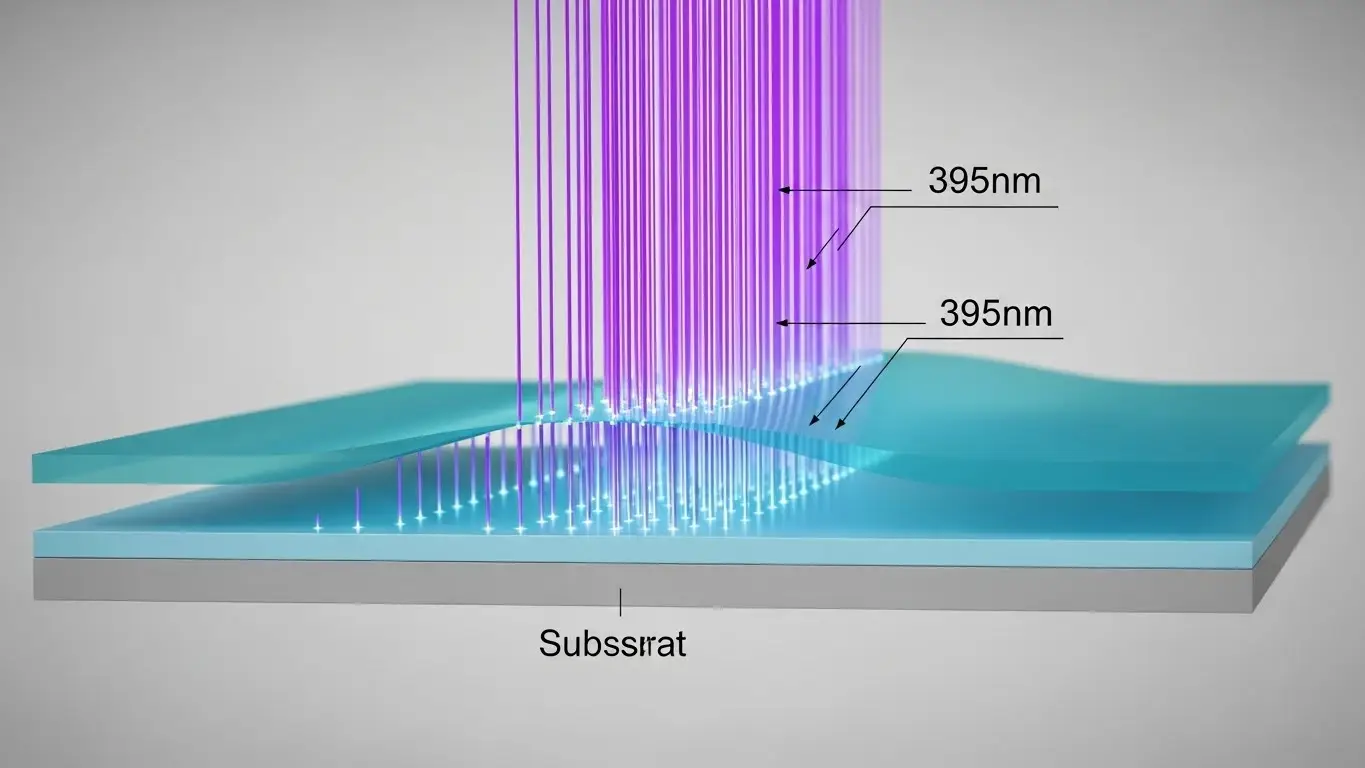

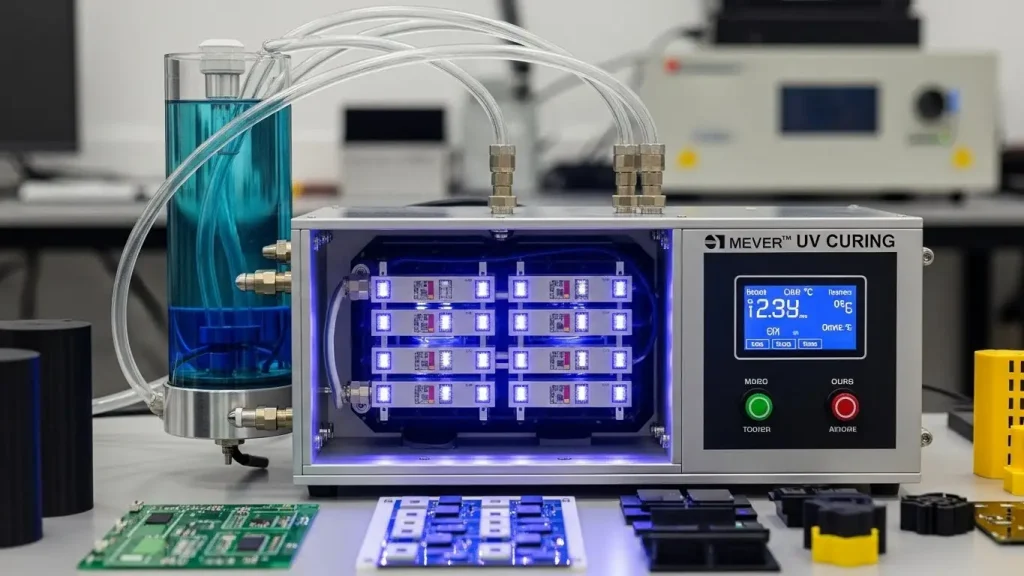

A water-cooled UV LED curing system uses circulating liquid to remove heat from the LED modules, enabling more stable thermal control and consistent output in demanding environments. This architecture typically features a closed-loop chiller connected to the lamp head via flexible hoses that carry a coolant—usually a mixture of water and corrosion inhibitors.

As the coolant passes through precision-engineered channels directly behind the LED array, it absorbs thermal energy much more effectively than air. This allows the system to maintain a lower and more uniform operating temperature, which is critical for high-density diode configurations.

Why Is Effective Cooling Important for UV LED Curing?

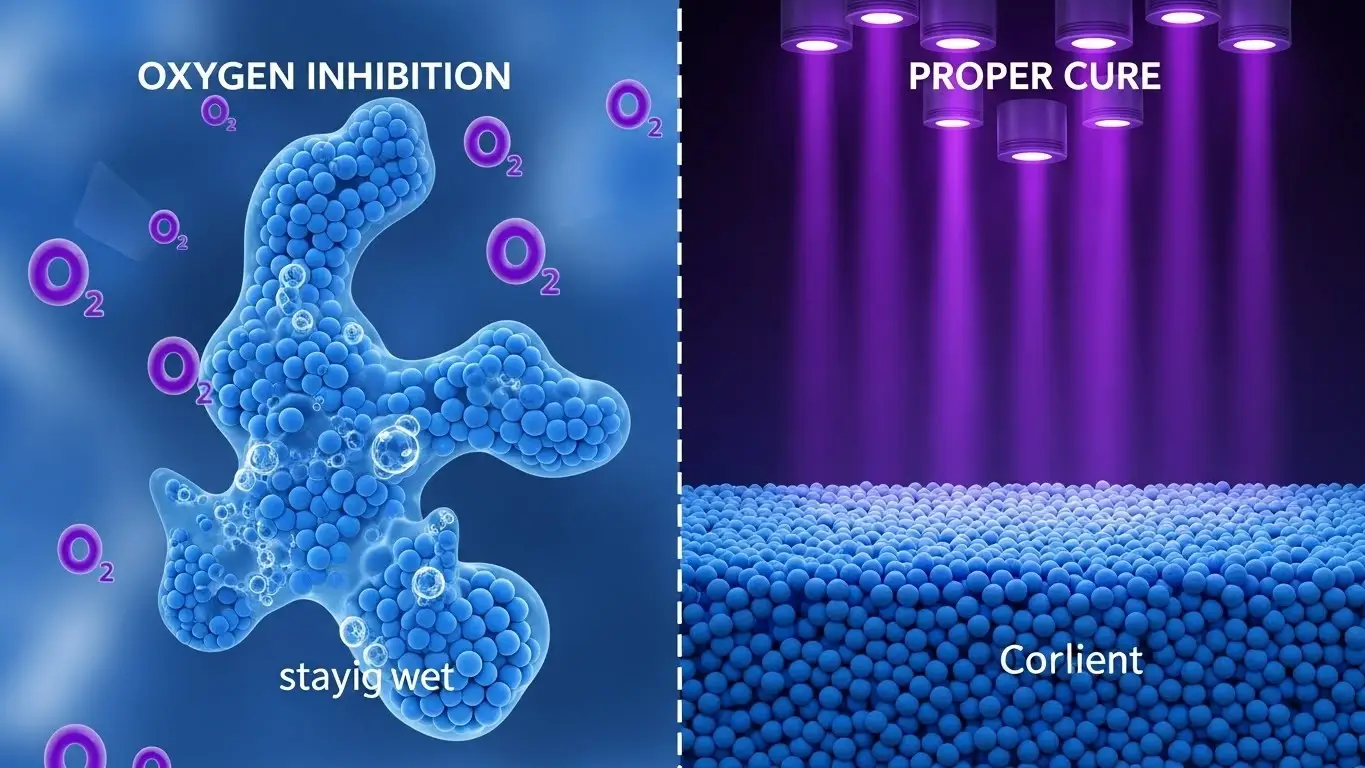

Effective cooling is essential for UV LED curing because heat buildup can reduce output stability, shorten LED life, and compromise uniform energy delivery over time. You will find that as the temperature of an LED chip rises, its efficiency in converting electricity to UV light drops, leading to a phenomenon known as thermal decay. Proper thermal management ensures that the peak wavelength of the light remains stable, which is vital for maintaining a perfect match with your material's photoinitiators. Without consistent cooling, your curing process could become unpredictable, resulting in variations in surface hardness or bond strength throughout a production shift.

When Should You Consider a Water-Cooled System?

You should consider a water-cooled system when operating at high power, extended duty cycles, or in environments where air cooling may struggle to keep temperatures controlled under load. If your production line requires peak irradiance levels exceeding 12–16 180°C, the heat generated often surpasses the dissipation capacity of standard fans and heat sinks. Continuous 24/7 manufacturing operations also favor water cooling because it provides a more stable thermal equilibrium over long periods. Additionally, if your facility is prone to high ambient temperatures or contains airborne dust that could clog air filters, a sealed liquid system offers a much more reliable thermal management solution.

How Does Water Cooling Affect Performance?

Water cooling improves performance by dissipating heat more efficiently, helping maintain consistent intensity, uniform energy distribution across the field, and reliable dose delivery over longer runs. Because liquid has a higher thermal capacity than air, it can keep the LED junction temperatures significantly lower even during high-output tasks. This superior thermal control translates directly into a flatter intensity profile across the curing width, ensuring that the edges of your substrate receive the same energy as the center. For high-speed processes where the curing window is only a fraction of a second, this stability is the difference between a successful bond and a production failure.

What Are the Practical Trade-Offs of Choosing Water Cooling?

Choosing water cooling involves trade-offs such as additional system complexity, potential space and plumbing needs, and more involved maintenance planning. You must accommodate a separate chiller unit on your shop floor and ensure that the plumbing is routed safely to avoid interference with robotic movements or conveyor paths. While the lamp head itself is often more compact than an air-cooled equivalent because it lacks bulky fans, the overall system footprint is larger due to the external cooling hardware. Furthermore, the initial capital investment for a liquid-cooled setup is generally higher than for a self-contained air-cooled system.

How Should You Evaluate Whether Water Cooling Fits Your Needs?

Evaluating water cooling involves reviewing production speed, duty cycle, ambient conditions, thermal load, and uniformity requirements in the context of your process goals. You should perform a technical audit of your line using the following criteria:

- Intensity Demand: Does your material require high irradiance to trigger its photoinitiators?

- Duty Cycle: Will the lamps be active for more than 70% of a production shift?

- Environmental Stress: Is the ambient factory temperature consistently high?

- Substrate Sensitivity: Does your product require the lowest possible radiant heat transfer from the lamp head?

- Process Consistency: Is any intensity drift over a shift unacceptable for your quality standards?

How Does Water Cooling Influence System Maintenance?

Water-cooled systems affect maintenance routines because they require monitoring coolant quality, pumps, and thermal interfaces to ensure consistent heat removal and uptime. You will need to check fluid levels and clarity monthly to ensure that no biological growth or sediment is restricting the narrow flow channels in the lamp head. Periodic inspections of the hoses and connectors are necessary to prevent leaks that could damage other electronics on the line. Additionally, the chiller's heat exchanger must be kept clean to maintain its efficiency, much like the filters on an air-cooled unit, but with the added complexity of managing a liquid circuit.

What Are the Key Takeaways on Water-Cooled UV LED Curing Systems?

A water-cooled system is a strategic investment for manufacturers who prioritize process stability and high-output performance. It is the technically superior choice for high-intensity, continuous industrial applications where thermal drift must be eliminated.

- Essential for high intensities and demanding duty cycles.

- Provides the best thermal stability, ensuring a consistent UV dose over time.

- Allows for a more compact lamp head design for tight integration.

- Requires a commitment to liquid circuit maintenance and chiller management.

What Specifications in a UV LED System Relate to Cooling Needs?

System power and irradiance directly dictate the thermal load. You can learn how to interpret UV LED curing system specs to determine your cooling requirements.

How Do Water-Cooled UV LED Systems Work?

Understanding the physics of heat transfer helps in process design. Explore the details of UV LED water cooling to see how the liquid circuit manages diode heat.

How Do Air-Cooled and Water-Cooled Systems Compare?

Choosing the right strategy depends on your intensity ceiling. See a side-by-side look at air-cooled vs water-cooled UV LED systems for more context.

How Does Intensity Impact Thermal Load?

Higher brightness always leads to higher internal heat. Review the relationship between UV LED curing intensity and heat generation for your application.

How Does Dose Calculation Tie Into Operating Heat?

The longer the lamp is on, the more heat accumulates. Use our guide to UV LED dose calculation to help manage your system's duty cycle.

How Does Uniformity Interact With Thermal Stability?

Uneven cooling can create localized intensity drops. Read about UV LED curing uniformity to see why thermal management is critical for a flat energy profile.

Why Does Lamp Temperature Matter for Water-Cooled Systems?

Monitoring your equipment protects your long-term investment. Explore how UV LED lamp temperature affects both output and diode lifespan.

How Does Water Cooling Affect System Maintenance Routines?

Liquid systems require a different upkeep schedule than air-cooled units. Follow our UV LED curing system maintenance checklist for liquid-cooled hardware.

Final Thoughts

Selecting a water-cooled UV LED curing system is a technical transition from general assembly to high-precision, high-volume manufacturing. While air-cooled systems offer simplicity, they cannot match the thermal rigidity and intensity capacity of a liquid-chilled array. By ensuring your cooling strategy is matched to your production duty cycles and material needs, you eliminate the primary cause of process drift and equipment failure. A well-maintained water-cooled system provides the predictable, stable environment necessary for the most demanding industrial bonding and coating tasks.