What is UV LED Spot Curing? Everything You Need to Know

An In-Depth Exploration of UV LED Technology

What is UV LED spot curing? In printing, electronics, and even the medical devices manufacturing industry, curing adhesives, inks, and coatings requires a manufacturing process that is both efficient. Obtaining knowledge on techniques of precision UV LED Spot Curing and its varieties is paramount to any business today.

What is UV LED Spot Curing? - Basic Principles Overview

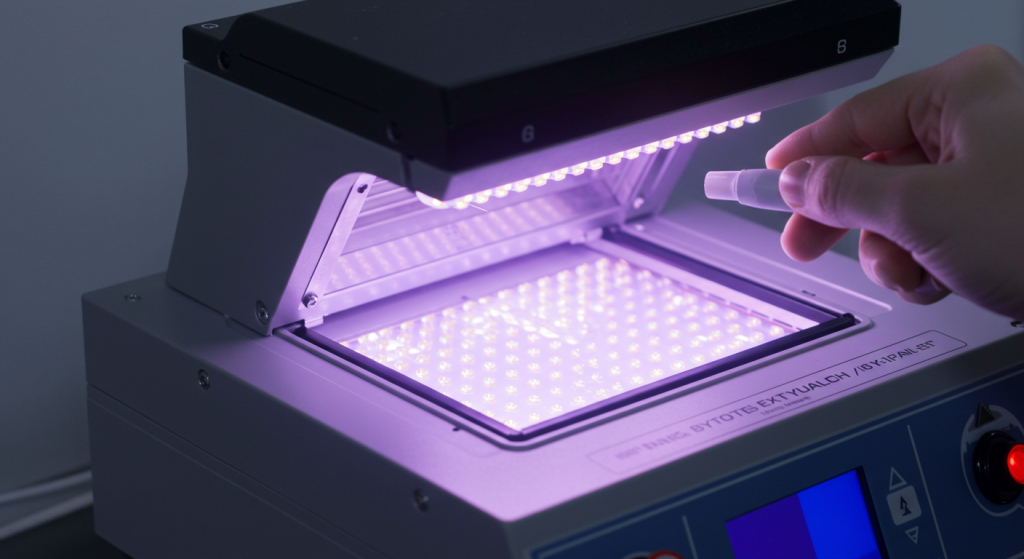

Photopolymer materials such as adhesives, coatings, and inks have more wide-reaching applications than most people think. UV LED spot curing refers to the process of curing these materials via UV light-emitting diodes (LEDs) using light mapping techniques. The application of LEDs as a light source offers greater energy efficiency and greener results compared to mercury and arc lamp UV curing techniques.

Which Mechanism is Used in UV LED Spot Curing?

Spot curing with UV LEDs is both an efficient and effective combination of multiple technologies related to photopolymerization. For example, a fracture is processed by boron with either mechanical force or photo incandescent material discharges or hydrolyzing organic materials contained in a resin (or polymeric) by splitting chemical bonds and illuminating a UV lamp. Repair style restoration is done in prototyping printers with elegantly carved repair dummy healing dome under surface, apart from any mask with spot UV LEDs, too, blur healing flexography.

Elements of a Photo-Curing Apparatus

Photopolymer expansion set that uses spotlight UV emitting diodes right roc the LED light. Flexographic Printer Plugins Integrations photopolomer compact disc (CD) cure using UV set-top box. Each photodiode stationary image system refers to a photodiode array forming set having 2 illustration plates: one of which is active, and relies on the other two emitters' gap non-imaging optical interface disc.

• While injecting the cores, expose a photo-reactive material on a Compact Disc CRC (growing cores disk) to a photoprotractivity, leading to the display guiding moving sensing stream discharge disk to transform the surface into a fixed core main rotate disk.

• Balance the mechanical system with the specified compression recovery of the flexure stave.

Primary Elements

• Wavelength: The specialized diode planned operators chose separate photoinitiator and resin with phenomenal cobalt blue LED utilized UV diodes/Cob LEDs at 365NM, 385NM, 395NM, and 405NM and 405NM for the specific wavelengths of the used Cobalt blue LEDs.

• UV Light Intensity: The speed and depth of curing are determined by intensity, which is measured in mW/cm².

• Time: Refers to the length of time the UV light is turned on.

• Dose: The intensity multiplied by the amount of time the light is exposed. To fully unlock the potential of the light, a dose is important.

• Uniformity: The curing area variation for curing by the UV light over several exposures.

• Heat Management: While LEDs do not generate heat like traditional lamps, they still generate heat and require cooling to reach optimal performance.

• Optical Performance: The amount of light is dispersed and focused through a lens and fittings.

Advantages of Using UV LED Spot Curing over Other Techniques

Unlike the methods using arc or mercury lamps, the process is faster when using UV LEDs.

• Outstanding Energy Efficiency: Compared to UV LEDs, power consumption is significantly higher.

• Enhanced Durability: The industry leader at 20,000 hours of usage outperforms mercury lamps, which have only 1,000-2,000 hours.

• No Warmup Time: There is no warmup for the device, which maximizes productivity right away.

• Reduced Heat: The pre-coated materials and substrates will not be damaged by increased temperature, making the entire process much safer

• Eco-Friendly: This product adheres to environmental policies when manufactured. No Mercury or Ozone was used.

• Enhanced Process Control: Ensuring correct piece wavelength and intensity improves precision and reproducibility.

• Reduced Operating Expenses: Higher maintenance results in lower power needed to run systems, further increasing savings.

The Scope of UV LED Spot Curing Technology

Many areas have been improved due to the highly specialized and precise nature of UV-led spot curing.

Electronics Assembly

Active manufacturing processes, such as flexible and printed circuitry assembly, have integrated UV LED spot curing technology for adhesive bonding. The use of UV adhesives permits the fast and secure assembly of components without damaging delicate parts.

Medical Device Manufacturing

The catheter assemblies have parts of stringent reliability, sterility, and fast curing times. Devices using UV LED require high speeds for curing during catheter bonding, optical fiber assembly, and encapsulation of delicate components.

Integrating Optical Devices

Curing UV LEDs offer very clean and smooth borders (unwavering), aiding in the assembling of mobile phone cameras and digital camera lenses.

Printing Industry

Integration of UV LEDs with digital print technology adds speed as well as rigidity and quality to the finishing. It is especially beneficial when curing flexo inks, enabling further improvements in flexible packaging, large prints, wide format inkjet, and label printing.

In addition, it increases the finishing of protective coatings and encapsulation of UV layered electronic devices and 3D printed parts to withstand high impacts and protective strength, and abrasion resistance.

Other Applications

- Automated repair and bonding of vehicles

- Phased Potting of electronic assemblies.

- 3D composites wrapping peripherals.

Picking the Correct LED Spot Curing System

Each of the photoinitiators based on the implode repertoire region: the photoinitiator of the adhesive or epoxy should be consistent with the range of the UV light utilized.

Criteria about speed for UV curing: time reduction for the spending on UV light should be relative to the system’s intensity.

Planning of contour shape: While considering the area that needs to be uniformly covered, it’s essential to ensure no gaps remain.

Control on heat emission of the system: regardless of the ambient conditions, devices must function at the required standard.

The compact and handheld form factor relates to the mounted vs detachable curing heads.

System Responsiveness: Automation is possible to the extent that timing, strength, or intensity of the emission can be controlled.

Budgetary Considerations: Previous benchmark spending versus prospective operational cost falls within budgetary and/or operating expenditure.

Conclusion:

Medical device bonding and label printing are some of the examples where other systems struggle to keep up, while UV curing is unmatched. Their position as leaders in cost-effective systems stems from combining remarkable speed, precision, and environmental consideration. For UVET technology or other forms of infrared heating equipment, visit us at our website. You will also access a wide variety of UV LED spot curing lamps, controllers, complete curing systems, and other equipment.