365 nm vs 395 nm UV LED Curing: Which Is Better and Why?

Choosing between 365 nm and 395 nm for your production line requires you to look closely at how ultraviolet energy interacts with your specific coatings. While both wavelengths fall within the UVA spectrum, they offer different results in terms of surface hardness and through-cure. This guide breaks down the technical differences and practical trade-offs of 365 nm vs 395 nm UV LED curing to help you select the light source that matches your material chemistry. By understanding these variables, you can optimize your manufacturing speed and ensure your final products meet your quality standards.

What Are the Fundamental Differences Between 365 nm and 395 nm UV LED Curing?

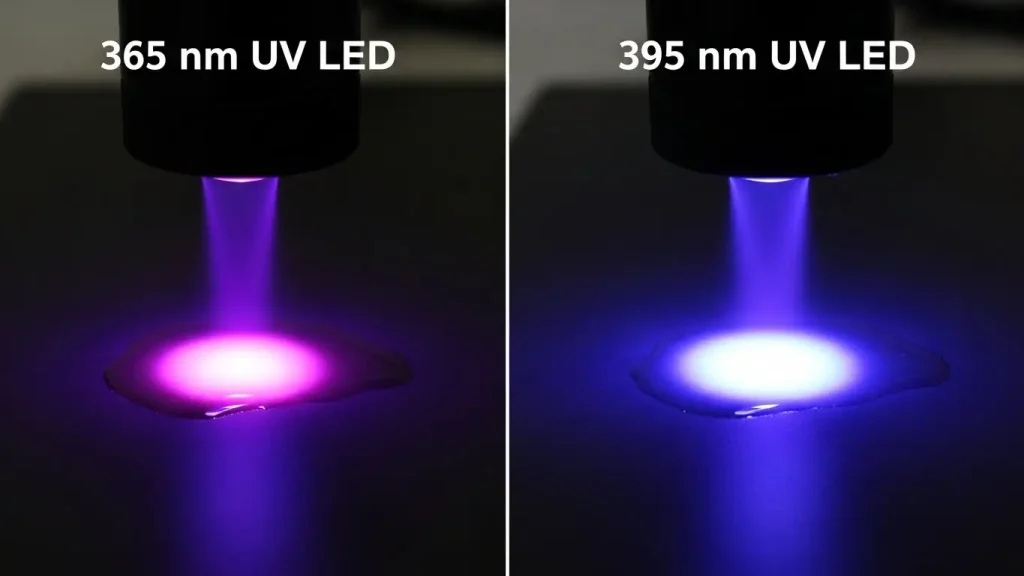

365 nm and 395 nm refer to distinct UV LED wavelengths with different energy profiles and material interactions. You will find that 365 nm light has a shorter wavelength and higher photon energy, making it very effective for surface-level chemical reactions. In contrast, 395 nm light has a longer wavelength and lower energy, which allows it to pass more easily through pigments and thicker layers. Your choice between them dictates how efficiently your lamp converts electricity into the specific energy your adhesives or inks need to harden.

How Does 365 nm UV LED Curing Perform in Practical Applications?

365 nm provides higher energy and deeper penetration, which influences how it interacts with certain photoinitiators and substrates. You often use this wavelength when working with clear adhesives or coatings that require a fast, high-intensity surface cure. It is particularly effective for legacy chemistries that were originally formulated for traditional mercury lamps. Because of its higher energy per photon, it can initiate polymerization in materials that might stay liquid or tacky under longer wavelengths.

How Does 395 nm UV LED Curing Perform in Practical Applications?

395 nm offers balanced performance with good energy distribution and is often suitable for a wide range of materials. You see this wavelength used most frequently in high-speed digital printing and label manufacturing because many modern inks are optimized for it. It is excellent at traveling through dense pigments, such as dark blacks or opaque whites, which often block shorter UV waves. This makes it a reliable choice for achieving a consistent "through-cure" in multi-layered or heavily filled coatings.

What Materials and Photoinitiators Favor 365 nm or 395 nm Curing?

Material photoinitiator chemistry is a key factor in choosing between 365 nm and 395 nm UV LED curing. You must align your lamp's peak output with the "absorption peak" of the photoinitiators in your resin. If your material is designed for 365 nm, using a 395 nm lamp will likely result in a failed cure because the energy is not absorbed.

- 365 nm Favor: Clear resins, thin-film medical adhesives, and traditional mercury-based coatings.

- 395 nm Favor: Opaque inks, thick industrial glues, and modern LED-specific wood finishes.

- Verification: Always check your material's Technical Data Sheet (TDS) for the recommended curing wavelength.

What Production Trade-Offs Exist Between 365 nm and 395 nm Wavelengths?

Choosing between 365 nm and 395 nm involves practical trade-offs related to depth of cure, speed, and material impact. You may find that 365 nm gives you a harder surface finish but struggles to reach the bottom of a thick layer. Conversely, 395 nm might provide a stronger structural bond at the substrate level but could leave the surface slightly soft if the dosage is too low. You must also consider that shorter wavelengths can sometimes be more aggressive on certain heat-sensitive plastics, even in an LED setup.

How Should You Evaluate Wavelength Choice for Your Specific Materials?

Evaluating wavelength involves matching spectral response to material behavior and verifying results with testing. You should start by consulting your material supplier to see if they offer a version of your ink specifically tuned for a certain nanometer range. Once you have a candidate wavelength, run test samples at your actual production line speed to ensure the bond meets your hardness and adhesion requirements.

- Check Spectral Absorption: Identify the peak absorption of your material's photoinitiators.

- Test for Depth: Ensure the light reaches the substrate through the entire coating thickness.

- Validate Surface Hardness: Check for any residual tackiness after exposure.

- Measure Energy Dosage: Use a radiometer to confirm your lamp provides enough energy at your required speed.

What Are the Key Takeaways on 365 nm vs 395 nm UV LED Curing?

The "better" wavelength is entirely dependent on your material's chemical formulation and the thickness of the coating. You get a harder surface with 365 nm for clear parts, while 395 nm is usually superior for pigmented and thick-film industrial applications.

- 365 nm is high-energy and great for surface hardness and clear adhesives.

- 395 nm is the mainstream choice for pigmented inks and through-cure.

- Success depends on matching the lamp to your specific photoinitiator.

- Testing at production speed is the only way to verify a successful wavelength choice.

How Do UV LED Wavelengths Differ Across the Spectrum?

You need to understand the wider context of the UVA band to make an informed decision. You can explore the technical differences between various frequencies on our UV LED curing wavelengths page. This helps you visualize where 365 nm and 395 nm sit in the broader industrial landscape.

What Are Typical Uses for 385 nm UV LED Curing Relative to 365 nm and 395 nm?

Sometimes the best answer lies in the middle of the common choices. You can learn about the balanced performance of 385 nm UV LED curing and the specific hardware like the 385 nm UV LED curing light. This wavelength often serves as a versatile bridge between surface and depth curing.

What About 405 nm in the Context of 365 nm vs 395 nm Decisions?

If you are working with very specific resins, such as those used in 3D printing or certain medical glues, you might consider longer waves. Read about 405 nm UV LED curing to see if a near-visible wavelength fits your material better than standard UV options.

How Does Photoinitiator Matching Improve Cure With Specific Wavelengths?

Aligning your light to your chemistry is the most important part of your technical evaluation. You can find out more about photoinitiator matching for UV LED wavelengths to ensure your bond reaches its full strength. This alignment reduces waste and improves your overall quality.

How Does Wavelength Affect Depth of Cure?

Understanding how light travels through your coating can help you avoid sticky spots on your parts. Check our guide on UV LED wavelength and cure depth for more technical details. This information is vital for engineers designing high-speed automated lines.

What Criteria Should You Follow to Choose a UV LED Wavelength?

You should follow a structured checklist when evaluating your light source to avoid costly mistakes. We have created a guide to help you choose a UV LED wavelength based on your specific job needs. This ensures you account for material, speed, and safety factors.

What Should You Know About 395 nm UV LED Curing Lamps?

As the most common industrial choice, this wavelength has specific equipment requirements. Look at our insights on the 395 nm UV LED curing lamp to see how it fits into modern production cells. It is a proven tool for many printing and assembly tasks.

What Should You Know About 365 nm UV LED Curing Lights?

Choosing a shorter wavelength often means selecting specific types of high-energy hardware. Explore the 365 nm UV LED curing light options to see how they deliver the "punch" needed for clear coatings. This frequency remains a cornerstone of precision manufacturing.

Final Thoughts on 365 nm vs 395 nm Selection

Finalizing your wavelength choice is about ensuring the technical alignment between your equipment and your chemistry. While 365 nm offers the high energy required for traditional adhesives and surface hardness, the 395 nm wavelength has become the standard for modern, pigmented coatings and high-speed production. Your goal should be to eliminate the guesswork by testing your specific materials under both sources. By focusing on the absorption needs of your photoinitiators and the physical thickness of your coatings, you can build a curing process that is both reliable and highly efficient. The right wavelength is the one that achieves a perfect cure without compromise.